3D printed consumer products have their own category in the 2019 3D Printing Industry Awards.

Be it Invisalign, i.e, 3D printed clear braces or Blamey Saunders’ hearing aids, manufacturers of consumer goods are increasingly turning to 3D printing. The technology has been integrated into many areas, not only to elevate the design of such products but to accelerate and optimize mass production.

The following shows the latest 3D printed consumer goods across fashion, beauty, sports, music and automotive, each suitable for nomination the upcoming 3D Printing Industry Awards. Or, you can select a 3D printed product that has yet to be highlighted.

Carbon and Riddell’s SpeedFlex Precision Diamond helmets

Earlier this year, Carbon, the Silicon Valley-based company behind Digital Light Synthesis (DLS) 3D printing technology, unveiled its latest system: the Carbon L1 printer as well as a partnership with American football equipment provider Riddell.

As the first company to work with the L1 printer, Riddell is using the system to 3D print Precision-Fit linings for its SpeedFlex Precision Diamond helmet.

The helmet is designed to absorb impact and provide excellent comfort for the athlete, thus, each lattice, generated by the Carbon Lattice Engine, is made up of over 140,000 individual struts. Also, a full lining for the helmet is composed of seven individually 3D printed parts.

Select players of the NFL used the Riddell SpeedFlex Precision Diamond helmets during the 2018 season. The helmets are commercially available from Riddell on a limited basis at the elite level from $409.99 (varsity) and $324.99 (youth).

Also within sports, in November 2018, Callaway Golf Company, a golfing equipment manufacturer, signed a consultancy agreement with GE Additive AddWorks to explore the potential of 3D printing for golfing equipment.

Brad Rice, Callaway Director, R&D Advanced Engineering, explained, “Callaway needs to learn how to use this tool [additive manufacturing] well, because it is inevitable that 3D printing of production parts is going to happen—it is the production method of the future.”

3D printed bicycle frames from Reynold

Last year, Reynolds, a UK manufacturer of bicycle frames and components, began using metal 3D printing technology to develop a range of customizable stainless steel and titanium frame-parts. This is intended to streamline production processes for frame builders in the cycling industry.

For a quote on 3D printed brackets, dropouts, and custom frames, visit the company’s website.

Chanel’s 3D printed mascara brush

In the fashion industry, last year, Chanel, began mass producing the 3D printed Volume Révolution mascara brush, made in collaboration with Erpro Group. Said to be the first of its kind, this brush was created using selective laser sintering (SLS), on industrial systems which produced up to 50,000 a day.

3D printing has allowed for microcavities in the core of the brush which holds a larger amount of mascara than previous brushes. Also, the brush’s individual strands feature a granular texture, increasing their surface area and the ability of the mascara to adhere to eyelashes.

At a cost of £28.00, the Volume Révolution mascara brush is available in 3 colors from Chanel and European beauty retailers such as Boots, and Debenhams.

Within bespoke accessories, Narbon, a Spanish 3D printing company, launched a service called 3DMemories, which creates 3D printed ceramic jewelry with ashes from a loved one.

The customer is required to send a portion of ashes in an urn to Narbon’s lab in Madrid. Following this, they are mixed with a variety of materials, including porcelain, and then 3D printed into a piece of jewelry. The jewelry is then packaged and shipped back to the customer.

Design a custom ring, bracelet, emblem and more here. The price of 3DMemories jewelry is disclosed upon the design request.

Formlabs and Gillette create custom 3D printed razor handles

In October 2018, Formlabs, a Boston 3D printer developer and manufacturer, partnered with Gillette, the shaving supply and razor brand of Procter and Gamble, to produce custom 3D printed razor handles.

Through this project, the partners are aiming to give consumers razors that best suit their grooming preference, budget, look, color, and style.

The Razor Maker handles are available in 48 3D printed designs sorted into one of three different levels of 3D printing, i.e. partially printed ($19), fully printed ($25), or with a chrome effect ($45). Design and order them at Razor Maker: powered by Gillette.

Additive manufacturing customizes cars with Mini Yours

MINI, a British automotive marque of BMW launched a service early last year which uses 3D printers for the mass-customization of its cars. Using the MINI Yours app, customers can add names and symbols to inserts for their car’s side scuttles or dashboard trims.

The custom-designed components are then 3D printed on-demand by MINI and colored either in “Aspen White”, “Chili Red”, “Jet Black”, “Melting Silver” or “White Silver”. The custom service is available for current MINI 3-door, MINI 5-door, and the MINI convertible cars. In addition, all of the 3D printed parts can be installed by the customers.

MINI customers can personalize their car’s side scuttles and cockpit facia for €145.00, as well as the LED door sills at a cost of €290.00, and LED door projector for €119.00. Get started on the MINI Yours platform here.

MINI Yours was shortlisted for a 2018 3D Printing Industry Award.

MINI also integrated Belgian personalization software provider Twikit’s customization software to provide mass customization services using 3D printing.

Carbon and Adidas running shoes

In 2017, Adidas announced a partnership with Carbon for shoes with 3D printed midsoles called the Futurecraft 4D. Last year, the partners unveiled the AlphaEDGE 4D LTD running shoes featuring the midsoles produced using Carbon’s DLS technology.

The Futurecraft 4D midsoles are made of UV-curable resin and polyurethane mixture, arranged in complex lattice structures. An initial batch of shoes with the Futurecraft 4D midsoles was available from $300. A further 5,000 pairs were released later in the year, by which time second-hand prices exceeded $20,000.

Following this, last month, Adidas unveiled a new iteration of its Y-3 4D Runner, also made in collaboration with Carbon. The latest Y-3 4D Runner is available from £449.00 on the Adidas Y-3 store.

Similarly, Reebok and BASF teamed up to create its first line shoes known as the Liquid Factory. In 2016, a limited run of 300 shoes with 3D printed outsoles was released at $189.50. The shoes were reportedly sold out in a matter of hours. Last year, the partners announced the production of the shoes. The price of the latest Liquid Factory show is yet to be disclosed.

Staying on footwear, Canadian custom footwear manufacturer Wiivv, and Dr. Scholl’s, a foot care brand owned by the pharmaceutical company Bayer, partnered last month to create customized 3D printed insoles.

Currently, the soles are available in full length and three-quarter sizes. Both sizes are now available to buy for $99.

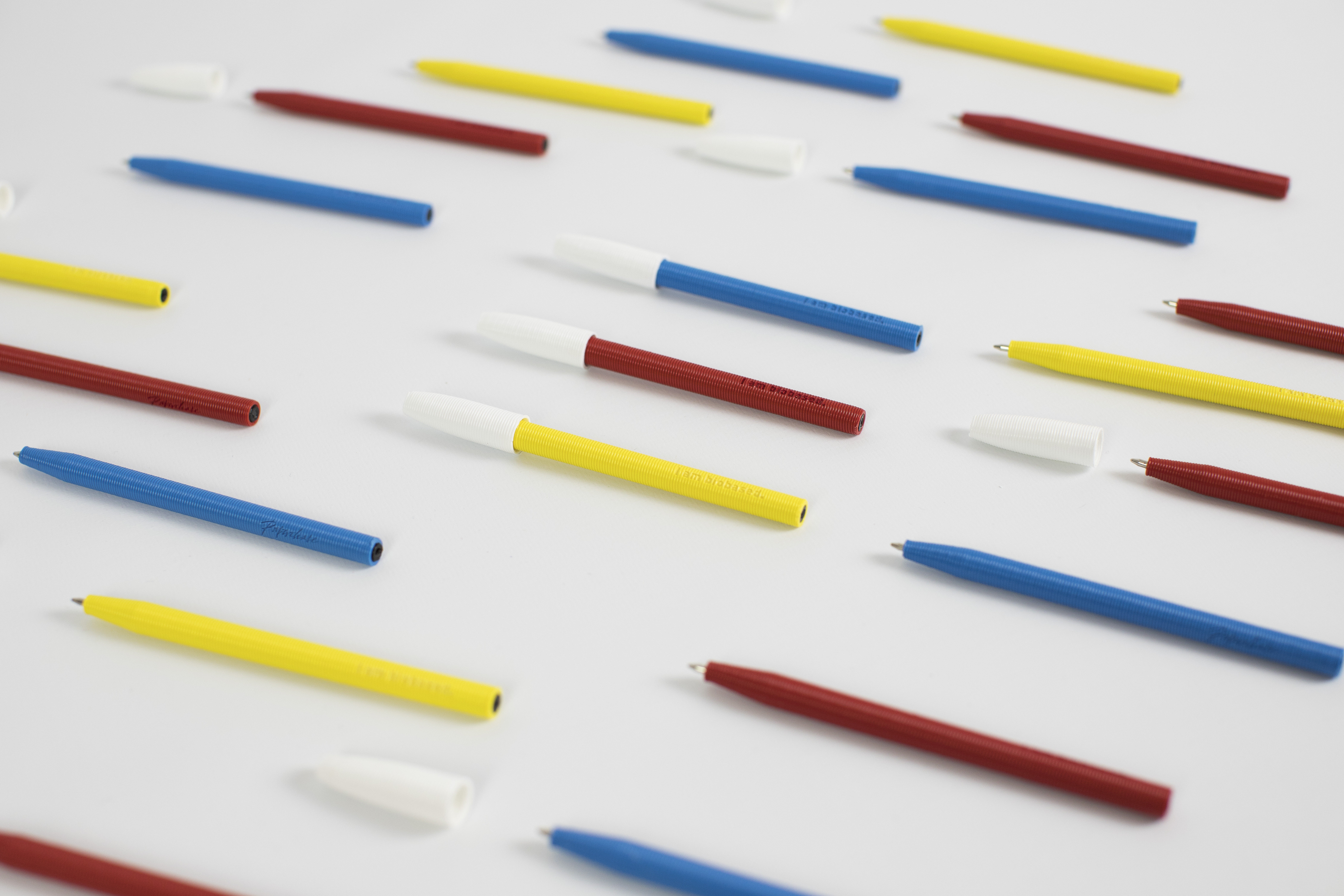

3D printed biodegradable stationery

Last month, Batch.Works, a London-based 3D printing service bureau, debuted its collaboration with international stationery store Paperchase to create a collection of 3D printed biodegradable paperclips, pen pots, and ballpoint pens. This selection of stationery is made from bioplastic and included in Paperchase’s Conscious Living collection.

Batch.Works additively manufactured 30,000 pieces of stationery within two months with Ultimaker 3D printers, then used an Epilog Laser system to engrave text on the parts.

Purchase the 3D printed pens from £3.00, 3D printed paper clips at £0.80, and a 3D printed 3-tray pen pot set for £15.00 from Paperchase now.

3D printed eye-wear

Recently, MOREL, a French eyewear brand, and INITIAL, a Seynod-based 3D printing service bureau, unveiled a range of glasses with 3D printed frames.

This line of eyewear is made in three different models using polyamide-based nylon and SLS. The side arms are made of a titanium alloy known as beta-titanium, one of the most common materials used in orthodontics. The glasses weigh 10g.

The glasses are presented in three different colors: Blue, Burgundy, and Black. The price is yet to be disclosed.

3D printed violins

For the musicians, 3Dvarius, a French manufacturer of 3D printed instruments, released its range of 4 and 5 string violins in October 2018, called The Line. The violins are 3D printed using stereolithography (SLA) and are available for purchase from €1149.00.

3D printed e-commerce service & showerheads

In April 2018, Voodoo Manufacturing, a New York-based 3D printing bureau, launched a new service, Fulfilled by Voodoo (FBV). This service connects directly to e-commerce storefronts in order for businesses to outsource all aspects of manufacturing, including 3D printing, assembly, and shipping.

Through FBV, Zooheads, a brand of Voodoo Manufacturing, is selling its 3D printed animal shower-heads. These shower-heads are 3D printed using FFF in a variety of colors from an eco-friendly PLA in 24-hours.

Purchase a shower-head from $29.95 here. Also, use the Fulfilled by Voodoo on-demand service here.

Don’t forget to nominations for the “Consumer product of the year” as well as other categories for the 2019 3D Printing Industry Awards.

Never be out of the loop on 3D printing. Subscribe to our newsletter, follow us on Twitter and like us on Facebook.

We also have a host of new jobs available on our 3D Printing Jobs page. Check it out for the best in additive manufacturing careers.

Featured image shows Clear Aligners being 3D printed via SLA. Photo via Youtube/Align Technologies, Inc.