In this edition of our 3D printing news digest – Sliced, we look at the expanding Asian market, a customized chest implant and the latest events from across the world. Read on for more from GE Additive, Roboze, KLM, Arkema, Additive Industries, Farsoon, Jabil, prizes for start-ups – and more.

The expanding Asian market

At the 2018 World Congress on Powder Metallurgy (PIM), held in Beijing, 10 Chinese companies came together to announce the expansion of their operations to meet demand in Metal Injection Moulding (MIM).

Among the companies who participated in the event was the Tianjin Zhujin Technology Development, an alloy powder producer for MIM. It recently expanded to brings its production to 30,000 tonnes.

Arkema, a French chemical producer, has announced the opening of a 3D printing service facility in Exton, Pennsylvania. The research in this center will be focused on photopolymer 3D printing.

The Exton facility will be an addition to an existing Arkema’s additive manufacturing center in King of Prussia, Pennsylvania, for filament extrusion technologies.

Furthermore, Sumeet Jain, Arkema’s Global Director of 3D printing said that the company will open a powder bed fusion facility in Mobile, Alabama. Jain further said that Arkema will expand its 3D printing capabilities to Asia by 2019.

Additive Industries, a Netherland-based metal 3D printing specialist, has announced that it will open its Process & Application Development Center in Singapore. The center will act as a hub for the development of additive manufacturing in the region. Earlier this the Dutch company also relocated its Eindhoven headquarter to a new factory, bringing its headquarter, Development and System Assembly, and Test Operations into one place.

Callaway Golf Company, a golfing equipment manufacturer, has signed a consultancy agreement with GE Additive AddWorks to explore the potential of 3D printing for golfing equipment.

Brad Rice, Callaways Director, R&D Advanced Engineering, said, “Callaway needs to learn how to use this tool [additive manufacturing] well, because it is inevitable that 3D printing of production parts is going to happen—it is the production method of the future.”

Jabil, a U.S-based manufacturing company, is participating in an evaluation program for Chinese 3D printer manufacturer, Farsoon. Jabil is testing the capabilities of HT1001P Polymer Laser Sintering (PLS) system. The machine is part of the Continuous Additive Manufacturing Solution (CAMS).

3D in the supermarket

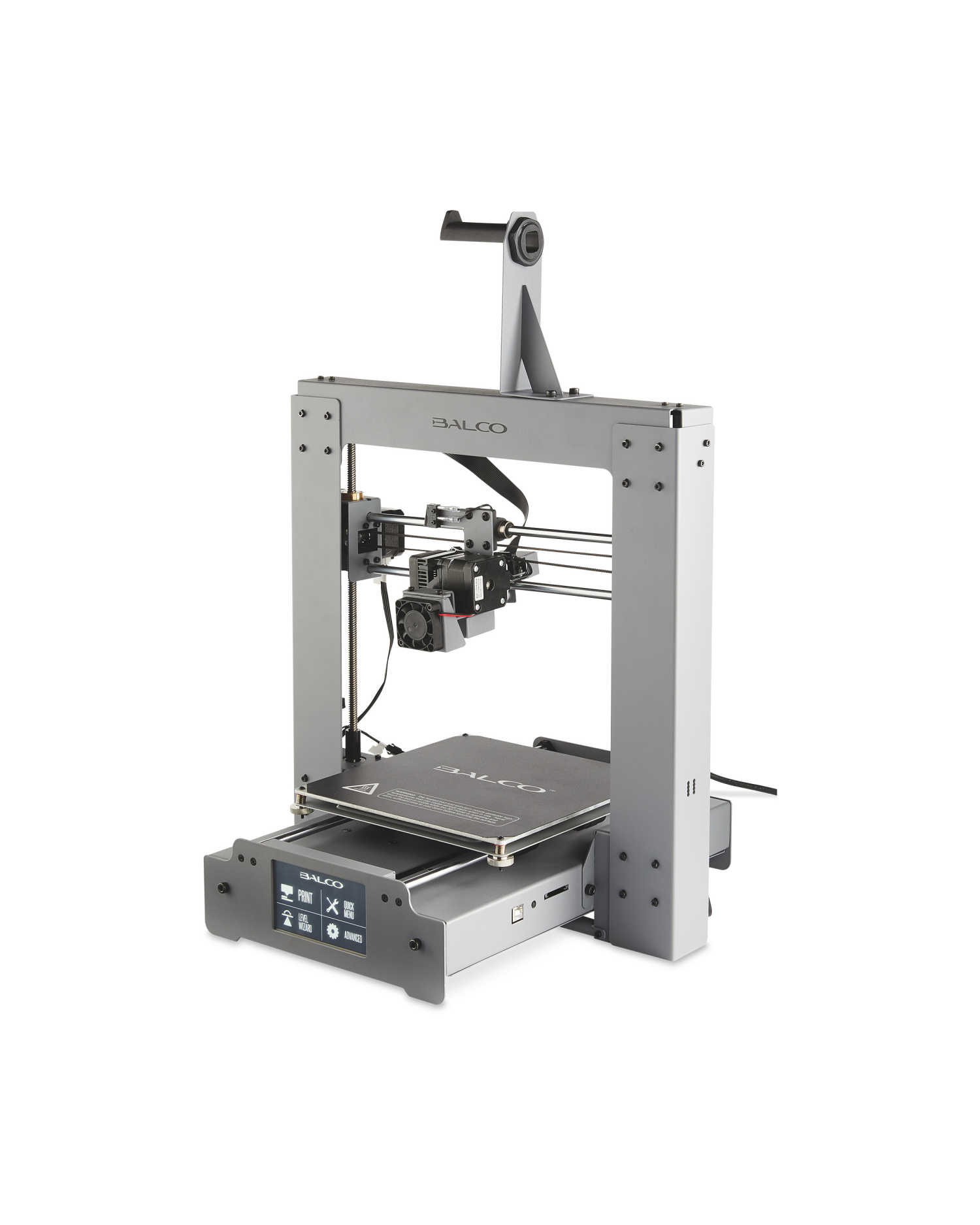

The German supermarket Aldi has brought the Balco Desktop FFF/FDM printer back in British stores. The single extruder Balco printer is equipped with a touchscreen LCD and can 3D print models between 20 x 20 x 18 cm with a layer resolution of 0.1 – 0.4 mm. The DIY kit can be bought for £299 and comes with a 100 meters PLA filament.

Twindom, a 3D scanning service provider, is offering personalized 3D printed portraits using Kodak full body 3D scanners. This service is available at New York and San Francisco Bloomingdale’s stores. The full body 3D scanning booth was launched by Kodak and Twindom earlier this year.

Design automation

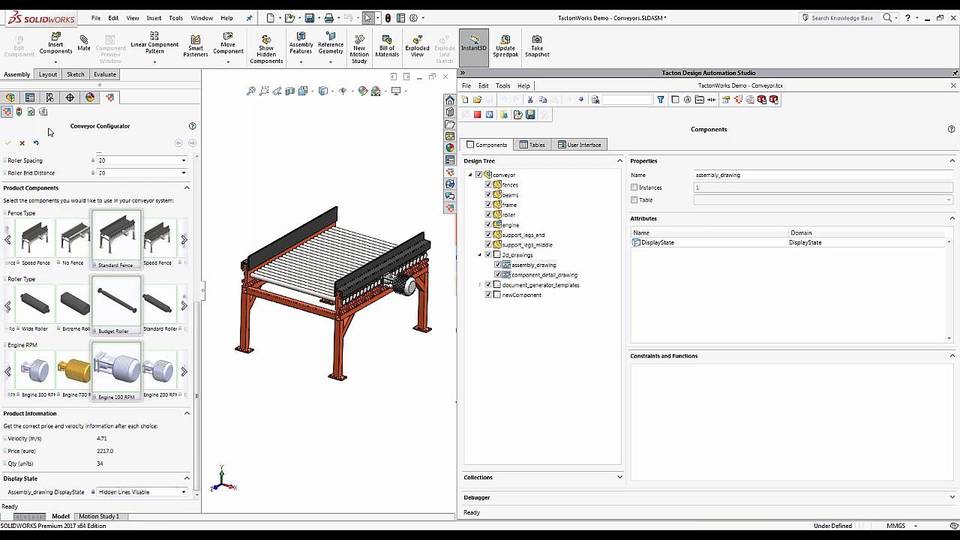

Tacton, a design automation and Configure Price Quote company, has received Autodesk Inventor certification. Tacton’s Design Automation software accelerates the process of design-making and provides quotations within the CAD tool.

Mathias Storm, Product Manager at Tacton said “We’re proud to once again receive the Autodesk Certified App logo and provide total integration with Autodesk Inventor. Together, we’re helping manufacturers get up to speed with Industry 4.0.”

Customizing healthcare

Anatomik Modeling, a Toulouse-based provider of custom-made implants, has designed a customized implant for chest using 3D technologies. The Anatomik Modeling’s team used 3D scanners made by Artec 3D, a Luxembourg-based 3D scanner manufacturer, and customized the 3D model using Geomagic Freeform software, a design software by 3D Systems. The prototype was then made with CNC machining.

Structo, a Singapore-based 3D printer manufacturer known for Mask Stereolithography (MSLA) printers, has appointed Doug Statham as Vice President of Global Sales. Doug Statham has worked in the dental industry for over 20 years. He was previously EnvisionTEC’s Director of Dental Channel.

Advancing prototyping capabilities

KLM, the flag carrier airline of the Netherlands, has acquired a Leapfrog Bolt Pro 3D printer. The Bolt Pro is equipped with a dual extruder which gives the option of printing a single object in two different materials. With a nozzle temperature of up to 360C, the Bolt Pro can print industrial-grade plastics. KLM is using the printer for prototyping aircraft parts. The 3D Printing Industry review of the Leapfrog Bolt Pro is here.

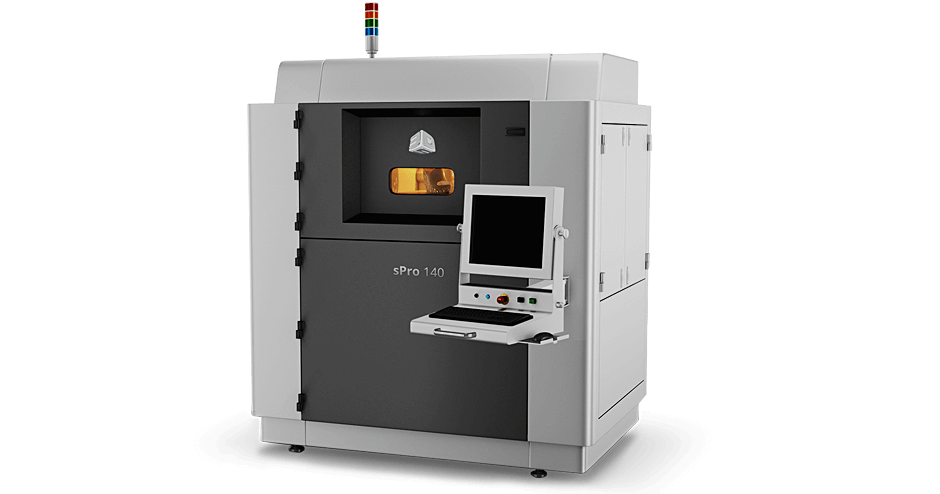

ARRK Europe, a product development company, has acquired a sPro 140 machine from 3D Systems. The SLS 3D has a large build volume and can produce parts of up to 550 mm in length. The machine was installed at ARRK’s prototyping center in Gloucester.

Ergonomic keyboard for a soft touch

Researchers at the Russ College of Engineering and Technology, Ohio University, have made a plastic and rubber composite to 3D print keyboard switches. According the study, the keyboard design can be improved with a 3D printed key switch which puts less stress on the fingers. The research paper was titled 3D Printed Composite Keyboard Switches, and co-authored by Alec Peery and Dušan Sormaz.

Adding more materials to the additive

Arkema’s business line Sartomer Europe introduced new materials, including UV resins and PEKK-based Graphistrength CM17-20 at this years formnext.

The latest UV resins include:

– N3D I-2105, an impact resistant material, can be used to produce functional parts

– N3D F-2115, a flexible material whose elongation modulation can be controlled to achieve the desired level of tear resistance

– N3D P-2125 offers good mechanical properties, ideal for prototyping

Bernstein Innovation, a German 3D printing materials company, has added the TPU70A to its materials portfolio. The TPU70A is a polyamide powder for laser sintering processes. It is used for parts which require strength and flexibility such as hoses and car bumpers.

Start-up of the year awards

Alessio Lorusso, CEO of Roboze, an Italian 3D printer manufacturer, has won an award from consulting firm Ernst & Young. The award was given at The Entrepreneur of the Year 2018 organized by Ernst & Young, one of one of the “Big Four” accounting firms.

Roboze is known for the ARGO 500 and manufacturing 3D printer for companies like CTC, a subsidiary of Airbus.

Rapid.Tech+FabCon 3D, an additive manufacturing exhibition organizer, has announced that registration for its Start-Up Award 2019 is open. Participation in the awards is free of charge and the prize money is worth €14,000. Registration closes on March 30, 2019.

Exploring nature through 3D printing

A Dutch architect company, Felixx Landscape Architects and Planners, has planted trees in 3D printed 2.6 m tall pots. The strip of planted trees covers 11 km.

The tree project is part of a research to understand the suitability and applicability of bio-based materials. The flask-like structures will be further tested over the next 2 years.

For more news on 3D printing subscribe to our 3D printing newsletter, and follow us on Facebook and Twitter.

Looking for a job? visit our 3D Printing Jobs.

Featured image shows Sliced logo over the 3D printed tree pots by Felixx Landscape Architects and Planners. Original image via Felixx.