Roboze, the Italian manufacturers of industrial 3D printers for high-performance engineering plastics, will provide machines to CTC GmbH, an Airbus Company.

At 3D Printing Industry we’ve followed Roboze for some time now. As leading industry analysts have noted, the use of advanced engineering materials and the ascent of the “plastic pyramid” is a notable development in additive manufacturing.

CTC focuses on the testing and evaluation of next generation industrial print technology and materials and is examining future applications in the aviation industry.

3D printing with techno-polymers PEEK, PEI

CTC GmbH and Roboze will work together on assessing with use of the Roboze machines to meet aircraft process and material requirements. According to a statement from the 3D printer manufacturer, CTC will feedback needs and boundaries for the 3D printing of advanced techno-polymers, including PEEK, PEI, to enable Roboze’s development of future products for the Airbus Group’s needs.

CTC GmbH, is a leading center in Germany for research and development for the design and manufacturing of complex components based on CFRP (carbon fiber reinforced polymers). The company are investigating ramping-up of production and support for serial production. CTC GmbH is also working on the next generation of 3D printing technology for the manufacture of composite parts.

3D printing driving future production

“In CTC we have always worked on consolidating the current production of aircraft components in composites and, above all, on anticipating future ones. 3D printing of engineering-grade plastics is one of them,” said Dipl.-Ing. Johannes Born, project manager leading the Additive Layer Manufacturing topics at CTC. Along with M.Sc. Sascha Backhaus, project manager in the Industrial Systems Department of CTC and expert for mechatronics and digitalisation, Born highlights the importance of these projects driven by 3D printing system and technology suppliers.

We were looking for an ideal solution to support our needs in terms of precision, technology and materials that offer high performance and high temperatures. By acquiring the new Roboze One + 400, CTC will assess its capabilities in order to accelerate the design and production of small series using advanced materials such as PEEK and PEI, thus enabling functional testing of real parts that might go into production in the coming years.

Developing future applications

With the introduction of the Roboze One + 400, and its capacity to print in 13 technical materials including PEEK, PEI and CarbonPA, Roboze say they are “revolutionizing the industry and the concept of additive manufacturing, enabling its customers to test in real conditions parts and assemblies before mass production, or to print short runs using high performance materials.”

The CEO of Roboze, Alessio Lorusso said, “We are excited to collaborate closely with the Airbus group and in particular with CTC and with high level engineers such as Mr. Born and Mr. Backhaus. We spoke extensively about the current needs of the group, which should be the goal for Roboze’s products now and in the future. We also had the opportunity to exchange ideas and opinions on the future applications that we can develop together.”

For all the latest 3D printing news, subscribe to our newsletter and follow our active social media channels.

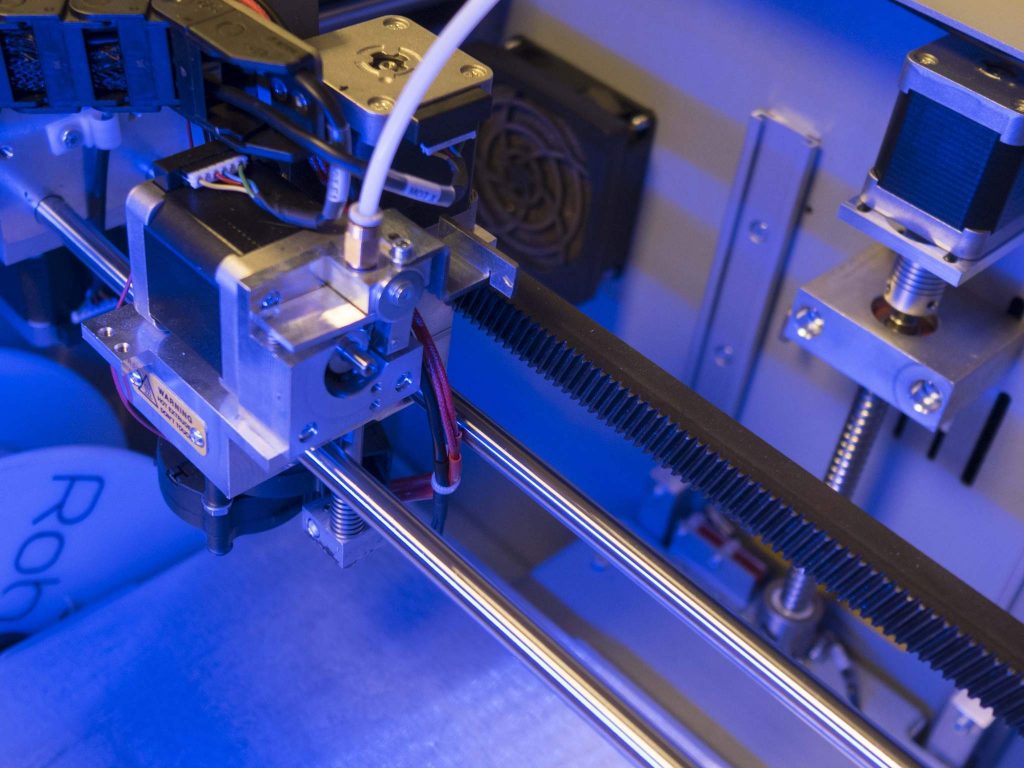

Featured image shows Roboze during Formnext 2016. Photo by Michael Petch.