3D Printing Industry is reporting live from RAPID + TCT 2018, to bring you the insider story on all of the latest 3D printers and trends in additive manufacturing.

In this article we have gathered together a first look of exhibits from the show floor, and presentations that set the pace for the day’s events.

3D printing high temperature metals

3D printing metal in high temperature environments, was the unifying theme of several announcements on day one of RAPID 2018. GE Additive released the Arcam EBM Spectra H additive manufacturing system for industrial 3D printing.

Arconic, an American company specializing in lightweight metals engineering and manufacturing, also announced that it is directing efforts to producing the materials necessary for high temperature applications.

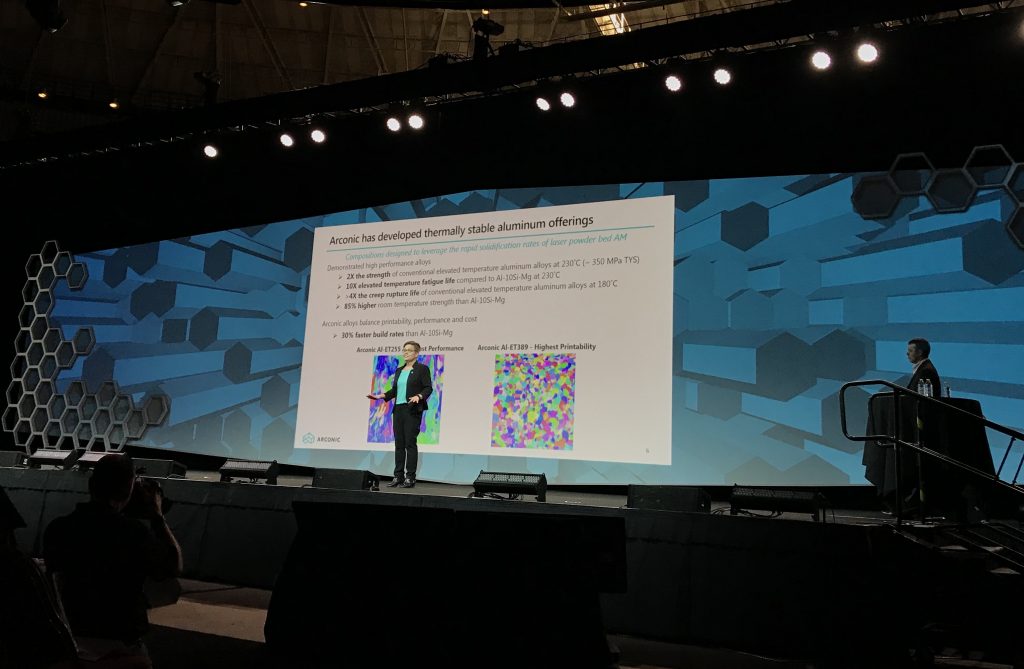

As the sponsor of the morning keynote presentations Arconic representatives Shawn Sullivan, Director of R&D, Materials and Surface Technology, and Dr. Lynne Karabin, alloys development lead, discussed the company’s efforts to produce aluminum alloys tailored specifically for additive manufacturing.

Karabin explained that often the problem with 3D printing metal alloys is that companies are looking to work with existing aluminum materials that aren’t optimized for the process. Instead, Arconic have developed high performance aluminum alloys, not substituting the conventional stock. These materials can work at elevated temperatures at 200°C and above. At room temperature, the printed parts also demonstrated 85% higher strength than its conventional counterparts.

New polymer systems

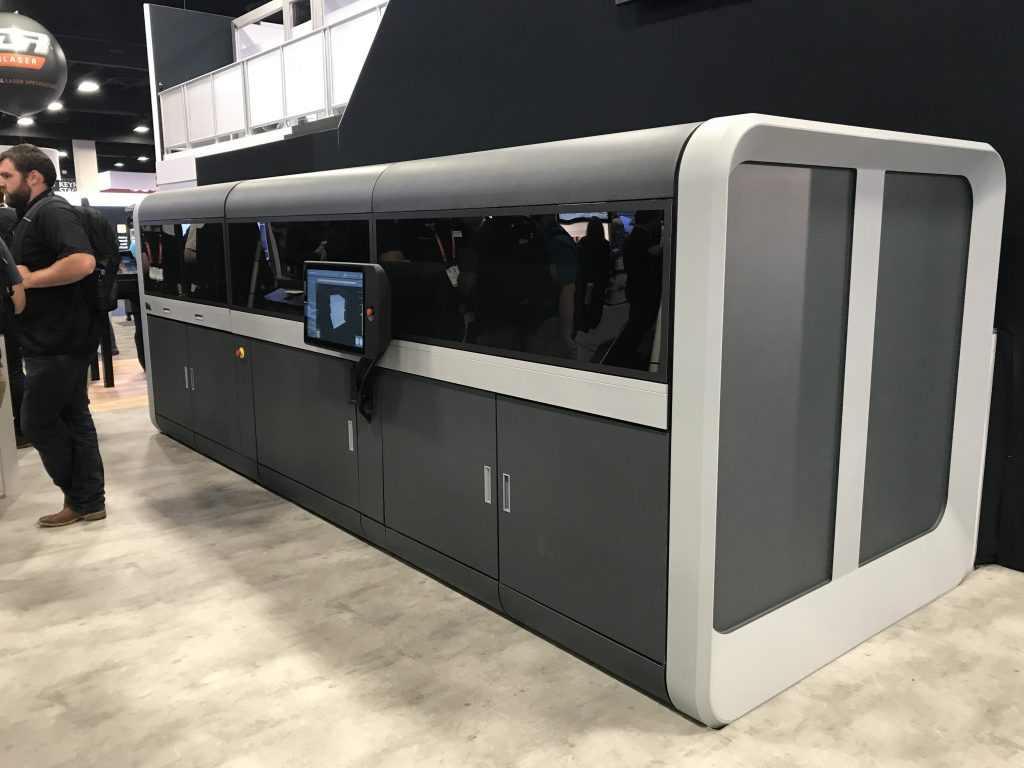

Tipped for release summer 2018 the HT1001P is a new polymer additive manufacturing machine from China headquartered, global 3D printer supplier Farsoon Technologies. The HT1001P is part of Farsoon’s Continuous Additive Manufacturing Solution (CAMS) with closed loop powder management, and a large build volume of 1000 x 5000 x 450 mm.

Recently, Farsoon has announced a number of partnerships to expand its global enterprise. In March of this year, the company signed a materials supply agreement with Swiss listed technology group Oerlikon in the hope of expanding additive solutions across China.

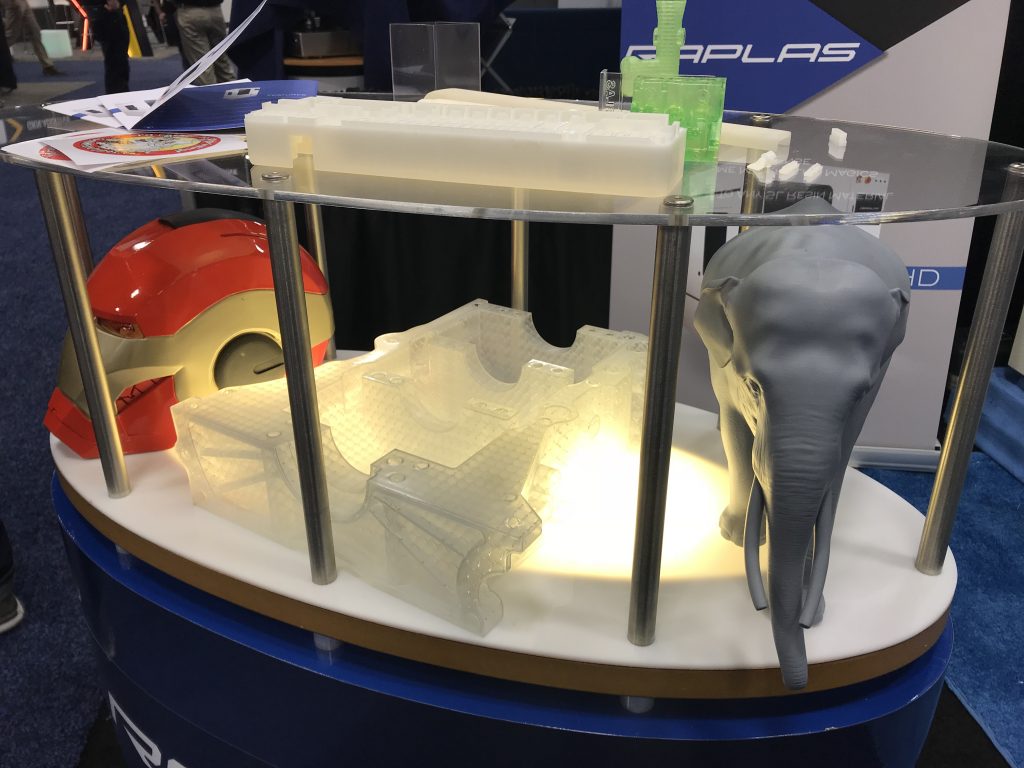

Custom Prototypes Inc., headquartered in Toronto, Ontario is debuting the RPS Gen 2. high resolution resin 3D printing system from RAPLAS America. The system is powered by Materialise Magics software, and features a build volume of 450 x 450 x 350 mm (for the RPS 2 450) or 700 x 700 x 450 mm (on the RPS-2 700).

3D Currax, a developer of 3D scanning technologies and 3D printers has also been tipped as “One to watch” by RAPID + TCT advisor Todd Grimm who is President of T. A. Grimm & associates.

“3D Currax has been privately developing technology that will advance production of mainstream products with a key focus on a process that can make optimal parts for their intended use,” commented Grimm at this year’s RAPID event.

“[It] took the combination of advanced additive manufacturing, custom robotics, AI, machine learning and development of key proprietary technology. In the end, they have designed an end-to-end system that makes finished 3D printed parts with no human interaction needed.”

3D printing for full scale production

In a poll taken by RAPID + TCT organizers SME, 61% of keynote attendees said that 3D printing for full scale production is the biggest potential opportunity in additive manufacturing, and a number of exhibits are keen to follow suit.

Award winning startup company Desktop Metal is exhibiting an in-operation Production System, tailored for the needs of enterprise customers.

In a catch up at RAPID with Desktop Metal CTO Jonah Myerberg he told me how an interaction with traditional subtractive technologies is key to the company’s ability to thrive in this industry.

Speaking in relation to the repeatability of Desktop Metal’s process, Myerberg says, “It took metal injection holding 30 years to figure this out, and we’re leveraging that knowledge in our technology.”

One other way of integrating additive in a traditional industry, is through hybrid manufacturing.

At Rapid + TCT 2018 Mazak is exhibiting the VC-500 AM HYBRID Mulit-Tasking Machine complete with full 5-axis capability and additive manufacturing technology.

In the coming year, Joe Wilker, Advanced Multi-Tasking Manager at Mazak tells me that the company will be expanding it’s additive profile to include automatically interchangeable printheads for a variety of metal additive methods including EBM and friction stir welding.

We’ll be reporting from RAPID all week, so say hello and let us know your thoughts about this years show.

For more of the latest additive insights from RAPID + TCT 2018 subscribe to our daily 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing. The 3D Printing Jobs board is live.

Vote now the leading industrial additive manufacturing systems in the 2018 3D Printing Industry Awards.

Featured image shows the keynote theater at RAPID + TCT 2018. Photo by Beau Jackson