A new collaboration between Swiss listed technology group Oerlikon (SWX:OERL) and industrial 3D printing solutions company Farsoon Technologies is seeking to increase adoption of additive manufacturing in China.

Under the terms of the agreement, Oerlikon will become the primary metal powder supplier and global partner for Farsoon 3D printers, delivering a convenient material and hardware solution to customers.

Dr. Xiaoshu Xu, founder of Farsoon and former technical director of selective laser sintering (SLS) company DTM Corporation (now 3D Systems), stated, “We look forward to working with a company known for its excellence and quality in the metal powder industry,”

“Partnering with Oerlikon as one of our preferred material suppliers can guarantee our customers a high level of material quality for their current and future applications.”

China’s additive manufacturing strategy

With an investment exceeding 20 billion Renminbi (US$3 billion) by 2020, the Chinese government has committed to an Additive Manufacturing Industry Development Action Plan to encourage widespread adoption of 3D printing across the nation.

In addition, a recent forecast by the International Data Corporation predicts that the Asia Pacific region (excluding Japan) will spend $3.6 billion on 3D printing over the next three years with a five-year compound annual growth rate (CAGR) of 22.4%.

To meet the growing market, Farsoon and Oerlikon will develop a new business model for additive manufacturing in China, creating an open platform system for all metal AM systems and encourage innovation.

New 3D printer materials

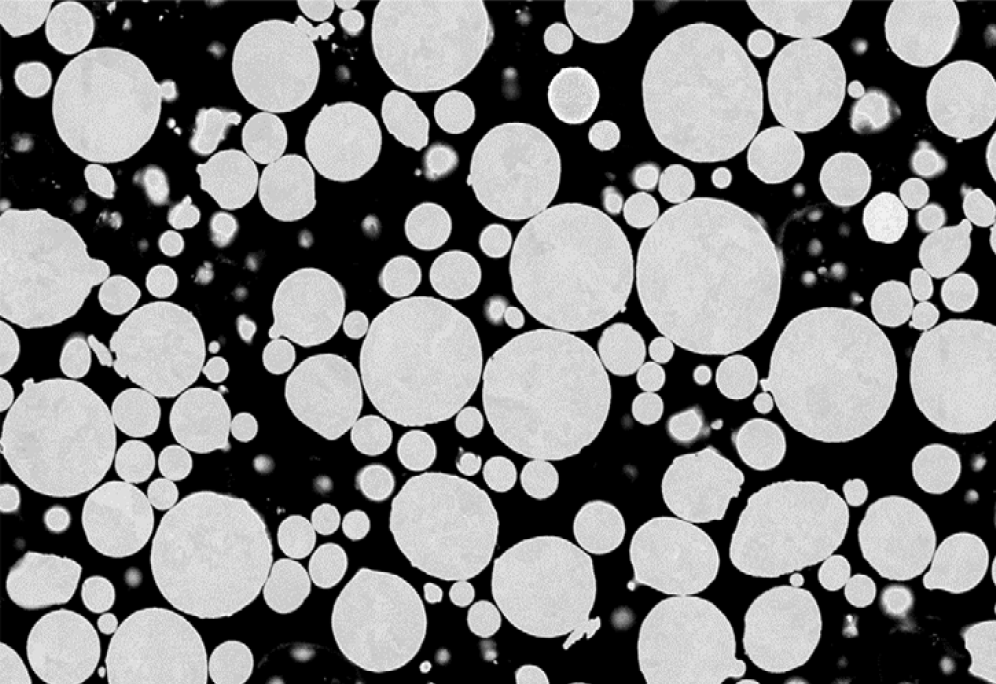

As part of the partnership, Farsoon will be qualifying Oerlikon’s MetcoAdd powders for use across its metal 3D printer range. Further, the two companies will work together to develop new custom alloys for the machines and conduct research and development projects in the region.

Florian Mauerer, Head of Additive Manufacturing Business Unit at Oerlikon, comments, “For new technologies, such as AM, partnerships and the development of new business models are key to unlocking their potential,”

“Working together with Farsoon, a fast growing AM machine manufacturer with a well-established presence in China, can set a new standard in the AM industry to bring integrated quality products and services to customers.”

For updates on the latest 3D printing partnerships subscribe to the most widely read newsletter in the industry, follow us on Twitter, and like us on Facebook.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your design now to win a 3D printer.

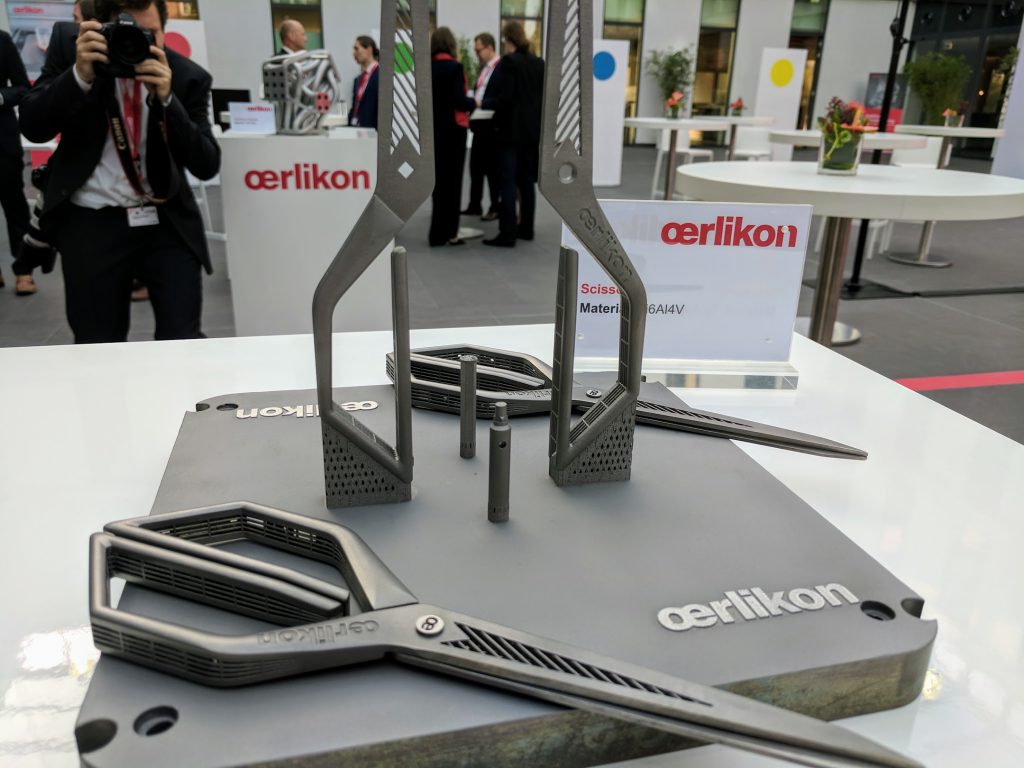

Featured image shows a custom mechanical part 3D printed by a Farsoon 3D printer. Photo via Farsoon Technologies