Industrial 3D printing solutions company Farsoon Technologies has entered into a collaboration with UK-based post processing specialist Additive Manufacturing Technologies (AMT).

The agreement was announced at this week’s TCT Asia conference currently taking place in Shanghai, China.

Joseph Crabtree, CEO of AMT, comments, “AMT is delighted to enter into this agreement to supply our post processing technology and solutions to Farsoon Technology,”

“The development of Farsoon’s continuous additive manufacturing is ground breaking and our involvement in assisting the delivery of this technology is very exciting.”

Automated post processing

Overcoming one of the biggest, and costly, challenges of 3D printing, AMT has developed an automated post processing system for polymer 3D printed parts.

The patent pending PostPro3D technology works on Multi Jet Fusion (MJF), Laser Sintered (LS), High Speed Sintered (HSS) and FDM made objects. It includes de-powdering and smoothing processes, that are otherwise labor intensive and expensive for manufacturers.

In 2017, 3D Printing Industry listed AMT as a UK “3D printing startup to watch” for 2018. Also last year, the company also received a £624,000 ($782,000) grant from government-run manufacturing accelerator Innovate UK to develop the technology.

Farsoon and AMT

Motivated to provide its customers with a complete additive manufacturing solution, this new collaboration from Farsoon will focus on the post processing stage of production.

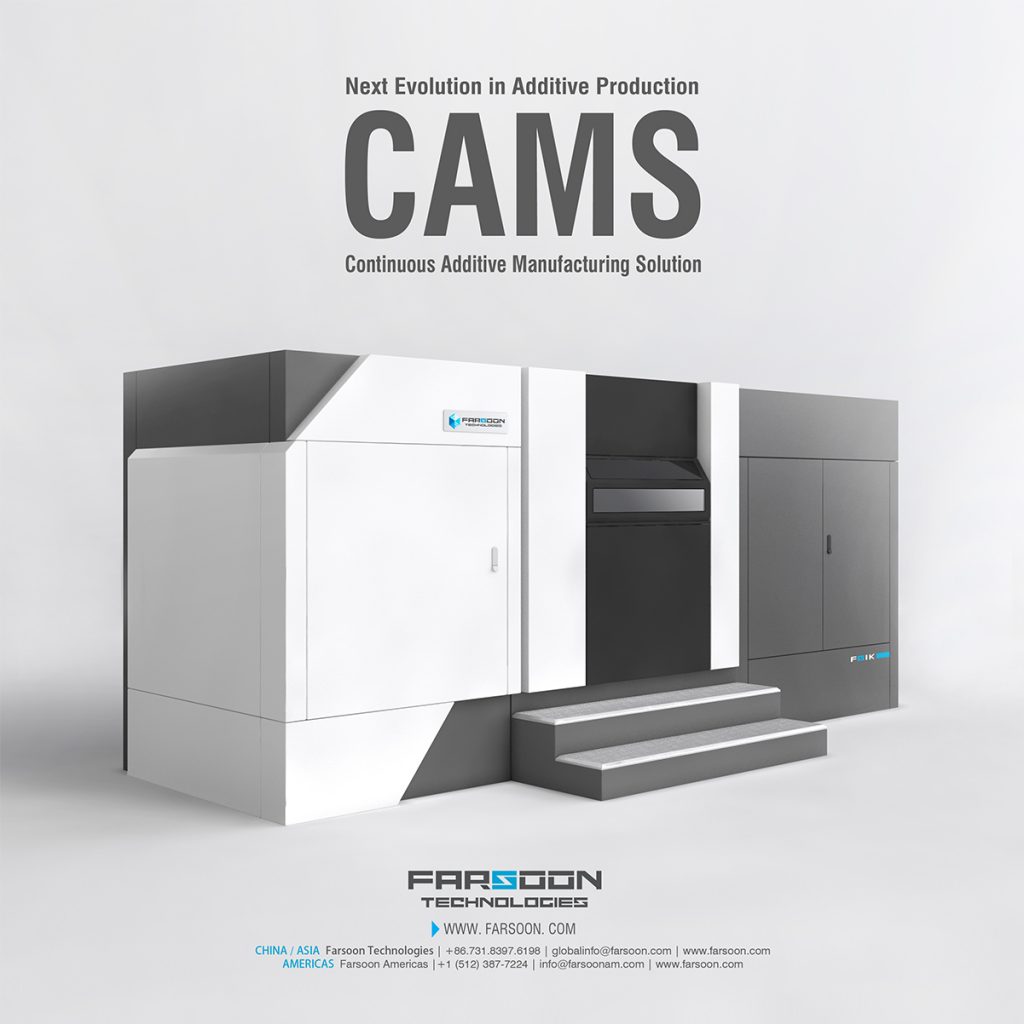

In the terms of the agreement, AMT will develop effective post processing solutions for Farsoon’s existing 3D printers and forthcoming Continuous Additive Manufacturing Solution (CAMS) systems.

A complete additive manufacturing solution

This week, Farsoon has also confirmed a metal 3D printer materials collaboration with Swiss listed technology group Oerlikon, to help promote the use of additive throughout China.

With materials, hardware, proprietary software and post-processing combined, Farsoon will be able to offer its customers a complete, streamlined 3D printing system for integration into new and existing manufacturing processes, helping move the technology toward serial production.

Don Xu, Farsoon Technologies Director of Global Business, concludes, “We are very excited to be working with AMT to provide an end to end solution for additive,”

“We have seen a definite movement both in China as well as globally of the additive industry moving towards manufacturing and coupled with that an increased demand for more streamlined post processing solutions,”

“AMT’s expertise in this field combined with Farsoon’s expertise in additive create a strong team with truly innovative solutions.”

For updates on the latest 3D printing business deals and technologies subscribe to the most widely read newsletter in the industry, follow us on Twitter, and like us on Facebook.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your design now to win a 3D printer.

Featured image shows an example of 3D prints that have used AMT’s PostPro3D PUSh process. Photo via Innovate UK.