This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

John E. Barnes is Vice President of Advanced Manufacturing and Strategy at Arconic Titanium & Engineered Products. Arconic (NYSE:ARNC) is a global technology, engineering and advanced manufacturing leader.

Making the Future Take Flight by John E. Barnes

The next five years for 3D printing are going to feel relatively more like hours than years as the industry takes off an an unprecedented rate. Analysts forecast the global aero 3D printing market will grow at an astounding 55% CAGR during the period 2016-2020 (TechNavio). And while it used to be said that the only people making money in 3D printing were the conference organizers, conference trends are another area where we can see AM heating up. For example, attendance at this year’s Additive Manufacturing User Group (AMUG) doubled from just two years ago and registration closed a week before the event. In 2017, RAPID is expected to be the biggest AM show ever, and Formnext will expand to a fourth day and double its exhibition space.

The incredible growth in AM is being driven by two factors. Industry’s desire to move to more affordable, lighter and multifunctional components continues to push one end of the additive manufacturing (AM) world. Simultaneously others are working to make the process more robust and repeatable. These are hugely positive signs that the technology is making an impact across multiple fields.

Where is AM headed?

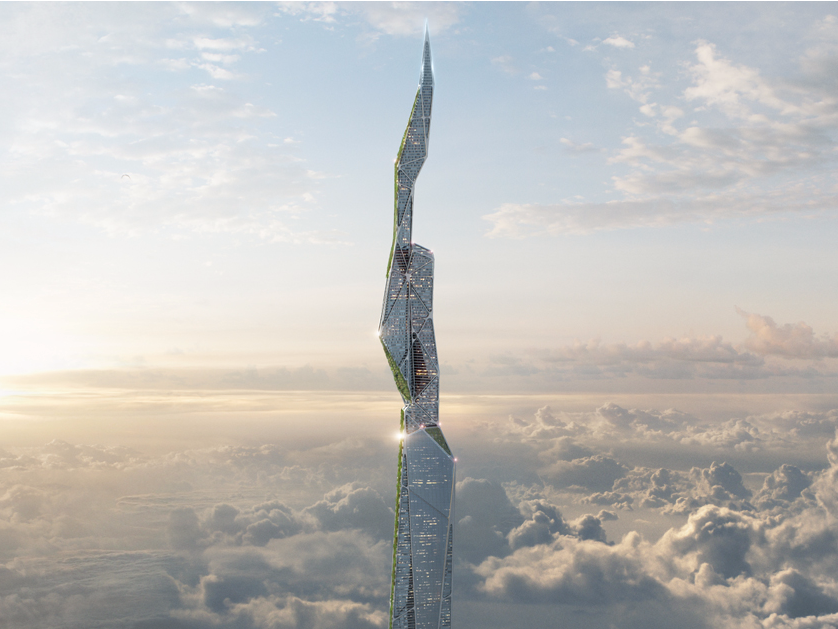

At Arconic we are focused on the industrialization of metal 3D printing for the large-scale production of aerospace parts. Primarily, this means tuning the equipment and process parameters to produce the same part, the same way, thousands of times. We of course will balance the equation with deep materials know-how and decades of aerospace qualification experience. We see the digital component of the technology expanding as well. This will include everything from advanced analytical methods and engineering to create robust build files in less time, to cybersecurity protection of IP, to anti-counterfeiting and enhanced quality control measures. We foresee AM equipment becoming increasingly more automated, more productive and more integrated in a factory as a system of systems.

3D printing overall will become more integrated. Design teams will accelerate their knowledge which will in turn push the envelope of lightweight and multifunctional design. For example, a student graduating high school this year may have already designed a 3d printed part during a class at school. As people integrate, communicate and collaborate, we will see more industrial integration as well. In addition to prototyping and direct 3D printing, hybrid AM processes, such as Arconic’s proprietary Ampliforge™ process, will enable greater efficiency by combining additive processes with legacy processes such as forging, for better and more predictable results. The future is taking off now.

The Challenges.

3D printing is revolutionary and yet it faces many of the same challenges of any new manufacturing technology. It has to do everything better than present methods and be more affordable. Yet, 3D printing is more complex than any manufacturing technology to come before it.

The materials world must deliver a 45-micron particle to a precise spot on a powder bed waiting for an energy beam to hit it. The powder must be the highest of quality in terms of chemistry, but also in terms of size, flow and spreadability performance. After it’s melted, the grain structure, the mechanical performance and the chemistry must come together to support the customer requirements.

The AM equipment must be capable of being a high-performance computer, high speed camera, intelligence gathering device, foundry, clean room and an electronics marvel all at the same time. And it has to get better every year.

The possibilities unlocked by additive manufacturing technology are nearly infinite.

When you combine the layer-by-layer manufacturing approach with the design flexibility it enables, 3D printing has the power to change the way we make virtually every product, in every industry. The “ink” in 3D printing is effectively infinite and in the next five years we will see existing materials become standard, and new materials emerge that are designed specifically for AM.

The world of 3D printing is multi-faceted and there are infinite areas within it to work. A former head of the famed innovation group Skunk Works™ was quoted once as saying, “Anything is possible as long as you keep it simple.”

I believe that innovation will come through focus on solving the issues and making constant, steady progress which is defined by customer requirements. The key to making this happen in the shortest timeframe is partnering.

Partner with your suppliers and partner with your customers. At Arconic, we see this as vital to success as there is no room for ignorance when a part has to fly at 30,000 feet. We partner with our customers and our suppliers to make sure we understand every step of the process and to ensure we can meet their requirements. We are also active in the open consortia and collaboration space, and at the university level, because this is where innovative AM approaches percolate.

If we want to accelerate the adoption, we have to bring in diverse minds to think creatively. We want to be Additive Ambassadors.

AM is taking off—and Arconic is committed to helping it soar.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information. For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels.

Don’t forget that you can vote now in the 1st annual 3D Printing Industry Awards.

More information about Arconic is available here.

#futureof3Dprinting