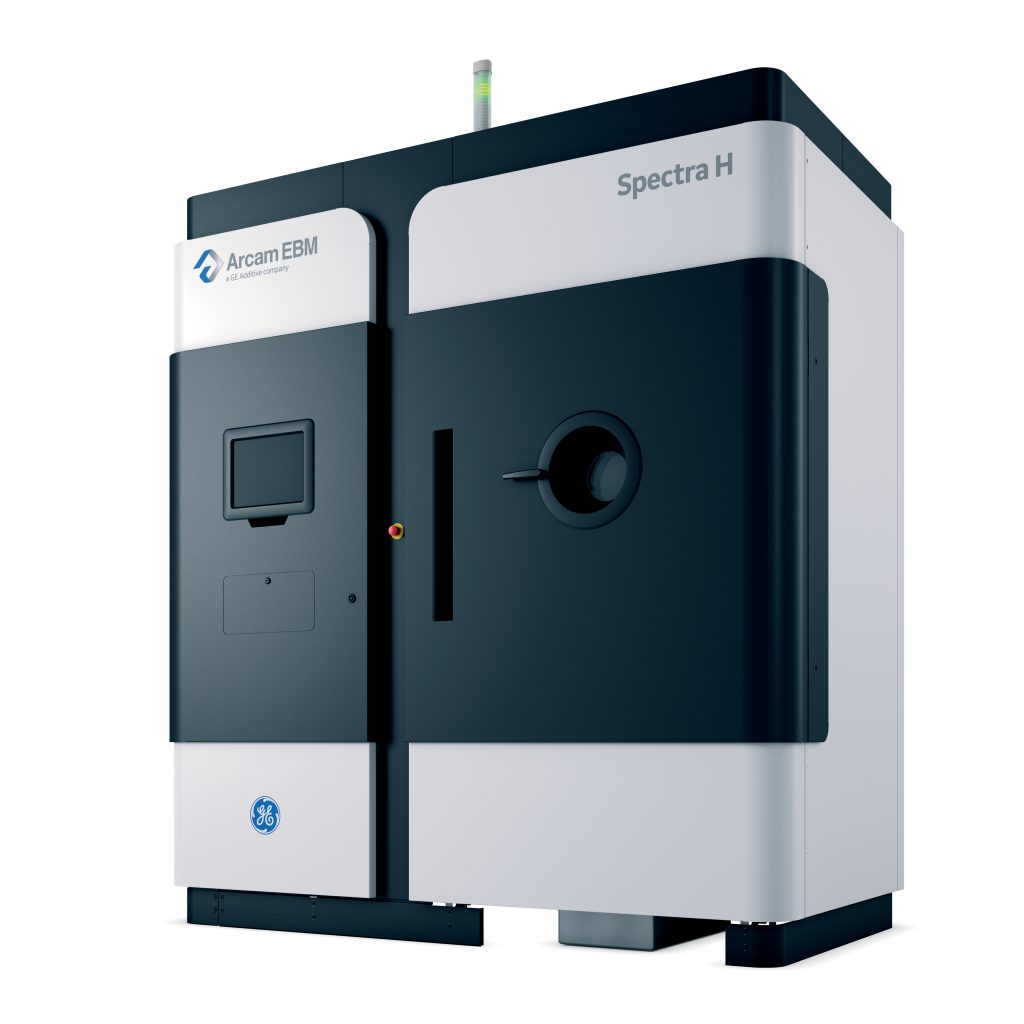

GE Additive has announced a new additive manufacturing system, the Arcam EBM Spectra H.

The industrial metal 3D printer has been developed to work with high temperature materials including TiAL and nickel Alloy 718. Improvements on the current Arcam range of metal 3D printers will boost productivity and throughput on this high-end line of electron beam powered machines.

Jason Oliver President and CEO, GE Additive said, “This new system shows our commitment to developing industry-leading additive machines, materials, and services. We remain focused on accelerating innovation across sectors and helping the world work smarter, faster and more efficiently.”

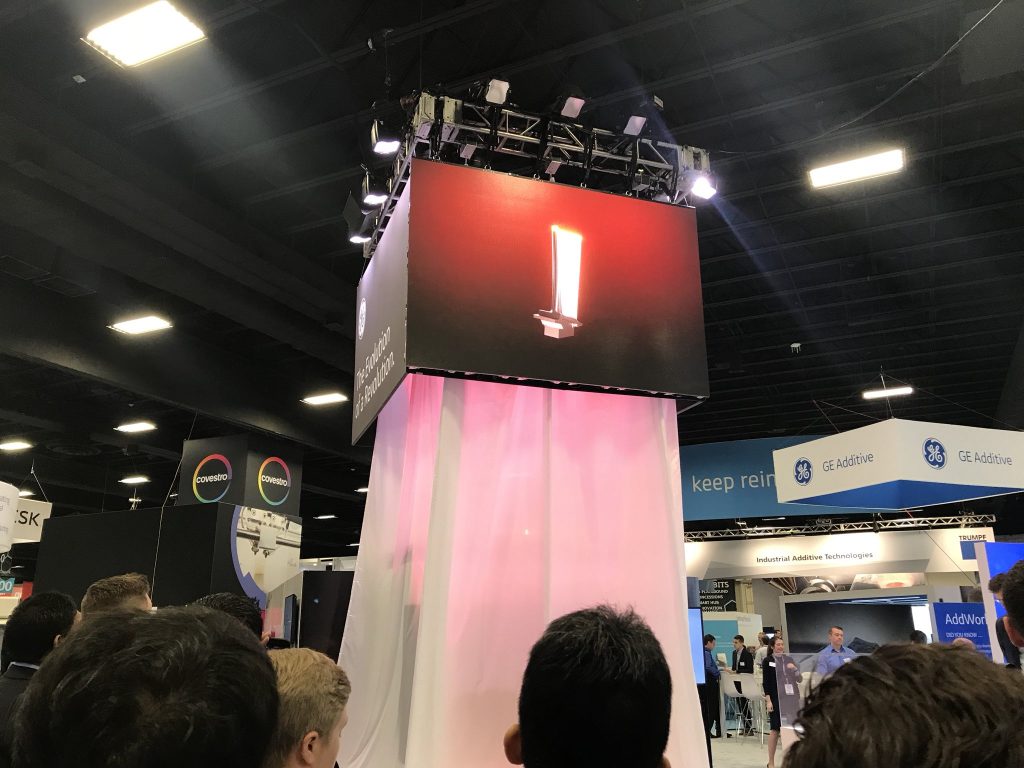

GE Additive says the Arcam EBM Spectra H has a 50% increase in build speed, combined with a 39% larger build volume. The metal 3D printer took center stage today at RAPID as the assembled crowd saw the unveiling of the new machine, while the Spectra H is available for pre-order at the show, delivery will not be until Q4 2018.

The industrialisation of 3D printing

The Arcam EBM Spectra H forms part of GE Additives vision for the industrialisation of 3D printing. A spokesperson said, “As manufacturers make significant steps towards serial production, they require larger, faster, industrialized solutions and machines that are capable of handling high heat and crack prone materials, such as titanium aluminide (TiAl).

Today, electron beam melting remains the only commercial additive manufacturing method able to support TiAl production requirements.

At launch the metal 3D printer will work with the materials TiAl and Alloy 718, with further Ni-super alloys available from 2019. The GE Additive materials science team is also investigating the use of a “wider range high heat materials, including; nickel superalloys, tungsten, CoCr, stainless steel and metal matrix composites.”

Karl Lindblom, general manager, Arcam EBM said, “It’s great to be able to show the Spectra H here at RAPID and get feedback from across the industry.”

We have created what we think is an amazing system that demonstrates how Arcam continues to push the possibilities of EBM technology. Spectra H is the result of really hard work by a cross-functional team from across the GE Additive family, supported by insights and feedback from a handful of internal and external customers.

Features of the Arcam EBM Spectra H include:

- A 6kW HV-unit means that all pre- and post-heating steps take half the time compared with current EBM machines

- Increased build volume from 200x200x380mm to Ø250x430mm

- Auto beam calibration

- Development of an automated, self-dosing sieve and hopper filling station process.

Innovations in calibration and increase in build speed

While the build speed of the 3D printer has increased by up to 50%, GE Additive says that further improvements are expected to raise this figure.

Enhancements to heat management with a moveable heat shield are designed to keep heat in the build area. A new layering procedure decreases heating requirements and will save an estimated five hours on builds using the full height of the chamber.

Using Arcam xQam auto calibration has resulted in better position and focus accuracy, reducing the need for manual calibration. This cuts down a calibration process of 3-4 hours to only 15 minutes. GE Additive say this particular innovation will also be incorporated on all Qplus Arcam systems.

“For materials management and powder handling there are also improvements. Powder weight is controlled inside the hopper filling station and simplified set-up is possible with automatic powder hoppers. These are “self-closing when lifted and self-opening when mounted in the Machine,” according to a spokesperson. Furthermore, only one powder distribution set up for each material only while, “Calibration of the fetch position only needs to take place during a material change, no longer before machine start.”

“The operator is protected from the powder. A dust tight environment in all steps of the process maintains powder batch integrity. Removal of unwanted particles is handled by a thorough process; a cyclone for small and low-density particles, a sieve for coarse particles and magnetic traps. Selection of PRS materials in contact with powder. Protection plates in the blasting cabinet are the same material as the powder. “

For all the latest news from RAPID, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Find talent for a project, or advance your career in 3D printing. The 3D Printing Jobs board is live.

Vote now the leading industrial additive manufacturing systems in the 2018 3D Printing Industry Awards.

Featured image shows the first look at the GE Additive Arcam Spectra. Photo by Beau Jackson.