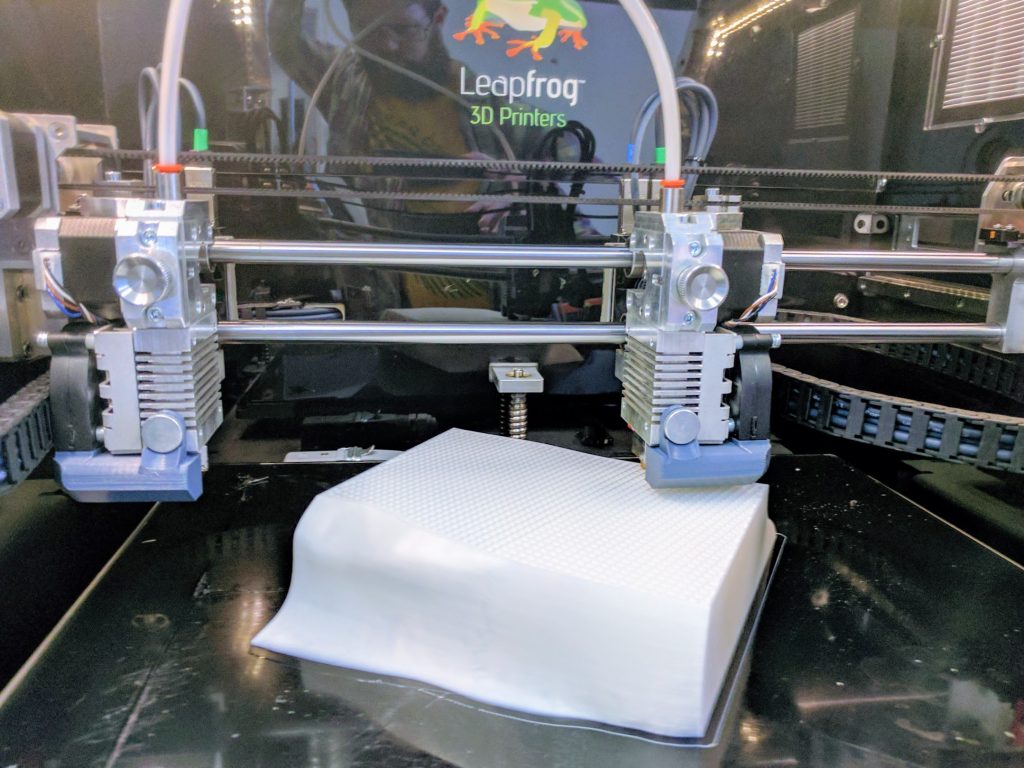

The Bolt Pro is the latest FFF 3D printer from Netherlands-based machine manufacturer Leapfrog. Fitted with independent dual extruders and an interchangeable print bed, the Bolt Pro is designed for user-friendly, professional 3D printing.

Recently, 3D Printing Industry put the Leapfrog Bolt Pro 3D printer through its paces in house.

Designed with the end user in mind

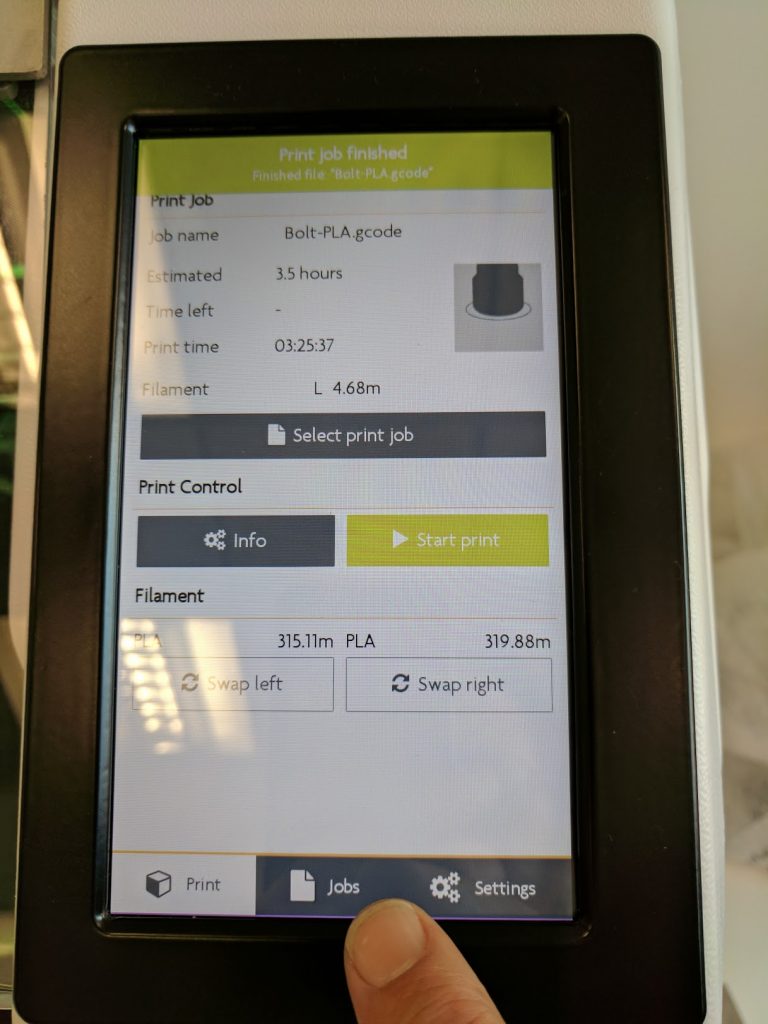

From the start it is clear that a lot of effort has gone into the user experience of the Bolt Pro.The integrated touchscreen gives a walkthrough on initial set-up, a useful feature for first time users familiarizing themselves with the technology. The interface is generally user friendly too, though it could benefit from a visible mouse pointer to indicate the user’s selection.

After manual bed leveling, the calibrated setting held well due to Leapfrog’s trademark high quality lead screws, included in all releases since the Creatr. Automatic bed levelling is also a feature the team are currently working on, which is due to be released in further generations.

Wi-fi connectivity proved stable, though the Leapfrog Bolt Pro also comes with the handy option to connect via ethernet cable if necessary. Working with the provided slicing profile on Simplify3D proved effective, giving good “out of the box” results and requiring no further tweaking.

The onboard camera is well positioned for monitoring print status, and demonstrated minimal lagging throughout all tests. Additionally, the magnet door closing mechanism is an improvement on the first Bolt, and filament storage is easily accessible, adding to the overall ease of use.

Print performance

Bolt Pro build size amounts to 320 x 330 x 205 mm (D x W x H) serving its purpose as an industrial-use machine. However, full use of the chamber could be further optimized along the Z axis to cater for taller 3D prints.

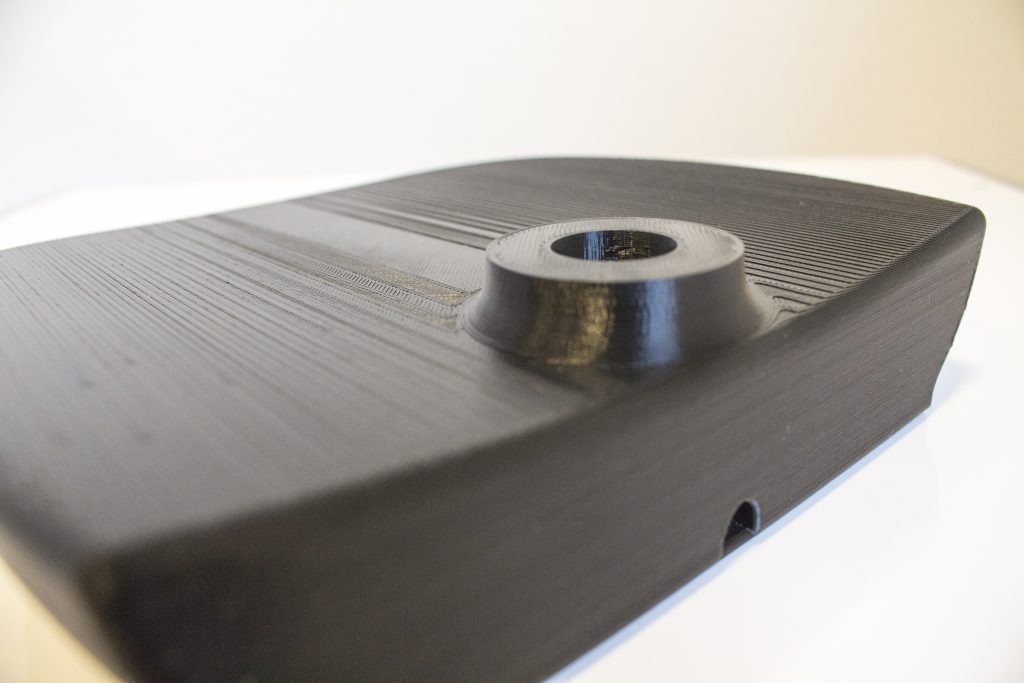

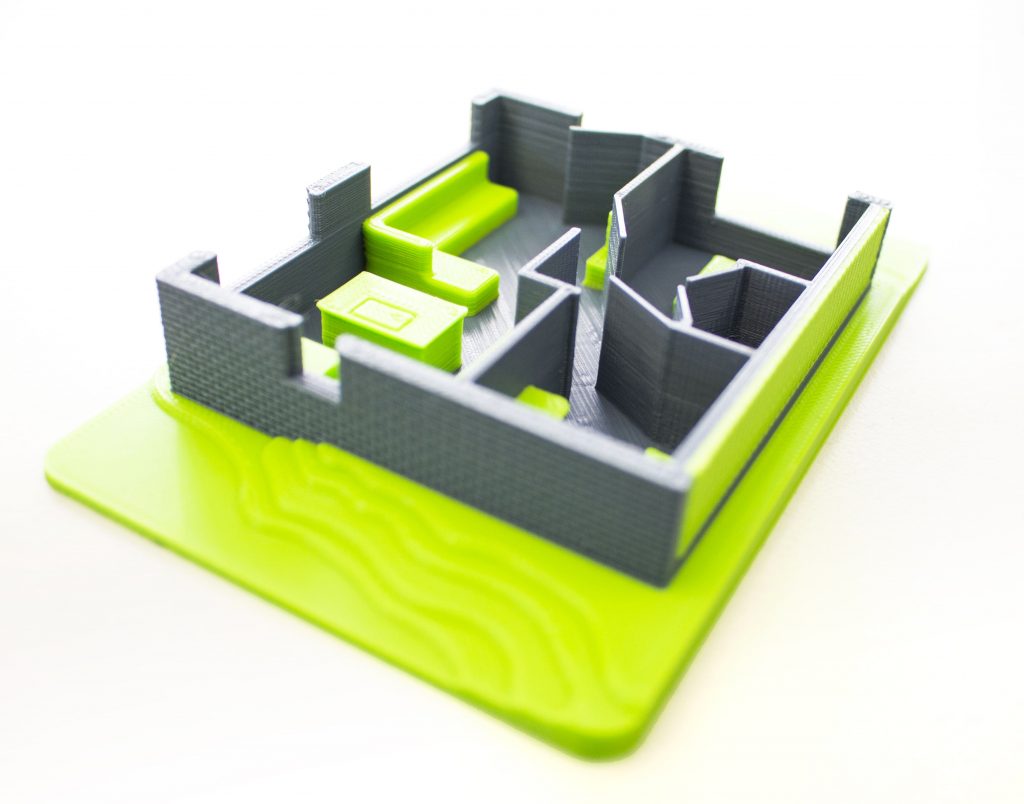

First, print quality was tested in a single color object using PLA, giving acceptable results. Next, quality of the dual extrusion system was tested, again using two spools of flexible PLA. In these two-color tests a degree of bleeding could be observed between the materials.

Dual-extrusion ability to meet the sample benchmark test sent by Leapfrog was average. With the included Leapfrog 3D SPRAY, prints demonstrated good bed adhesion avoiding any issues with the all important first layer.

The max temperature achievable by a Bolt Pro hotend is 270 °C for standard printing, and 360 °C for high temperature polymers. Operating temperature is typically between 15 and 30 °C (59 and 86 °F), and the bed can be heated to 90 °C (194 °F). In-built head maintenance is a valuable function for high volume users running a variety of settings. It also gives users the ability to manual select temperatures and exchange printheads, making the Bolt Pro an overall versatile machine.

More information about the Leapfrog Bolt Pro is available here.

Full technical specifications

Physical dimensions: 723 x 831 x 801 mm (28.5 x 32.7 x 31.5 inch) D x W x H

Printer weight: 61 kg (134 lbs)

Input voltage range: 88 – 264VAC

Input frequency: 47 – 63 Hz

Power consumption: 600W

Operating temperature: 15 to 30 °C (59 to 86 °F)

Build size single extruder: 320 x 330 x 205 mm (12.6 x 13.0 x 8.1 inch) D x W x H

Build size dual extruder: 320 x 300 x 205 mm (12.6 x 11.8 x 8.1 inch) D x W x H

Build size replicator/mirror mode: 320 x 164 x 205 mm (12.6 x 6.5 x 8.1 inch) D x W x H

Build volume: 21.6 L (4.8 gall.)

Heated bed max temp: 90 °C (194 °F)

Closed chamber: Yes

Hot end Max temp: 270 / 360 °C, 518 / 680 °F (standard / high temp)

Number of extruders: 2

Extruder size(s): 0.35 mm – 02 inch

Filament size: 1.75 mm – 02 inch

Layer thickness: 0.05 to 0.35 mm

Advised printing speed (DW): 6000 mm/min 100mm/s

Max. travel speed (DW): 15000mm/min 250 mm/s

Stepper motors: 1.8° Step angle with 1/32 micro stepping

Positioning accuracy (DW): 0.008 mm – 04 inch

Positioning accuracy (H): 0.010 mm – 04 inch

Body/frame construction: Aluminium Framework

Heated bed construction: High grade glass

Semi – automatic printbed Z – levelling: Yes

Ethernet connection: Yes

Wifi: Yes

Internal operating system: Linux

USB standalone format: .Gcode format

Printing modes: Single, Dual Material, Replicator mode, Mirror mode

Open system print materials (** experimental): PLA, ABS, HIPS, Flex, Nylon, Hybrid, Woodfill, PVA**, Carbon**, other**

For more 3D printing news, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

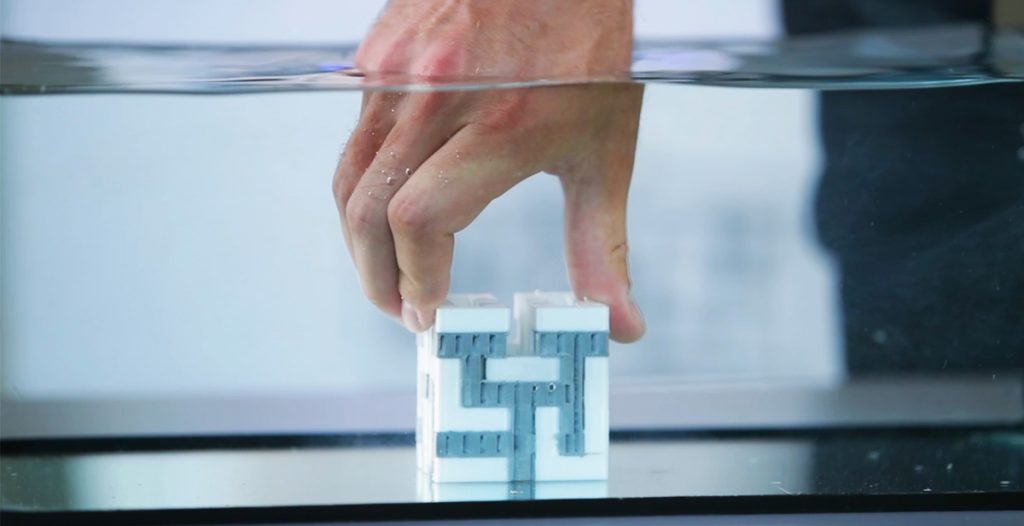

Featured image shows a photo of the Leapfrog Bolt Pro 3D printer. Photo by Michael Petch.