GE Additive has signed a memorandum of understanding (MoU) to develop additive manufacturing capabilities in the Korean aerospace industry. The agreement has been set up between GE Additive and two other entities, Korea Aerospace Industries Association (KAIA) and the Incheon Industry-Academy Collaboration Institute (IIACI).

Oh-jung Kwon, Vice Chairman of KAIA, said, “We hope that the agreement with GE Additive will serve as an opportunity for domestic aerospace companies to expand their capabilities in manufacturing aircraft parts and expand into the global market.”

South Korea’s aerospace AM project

Established in 1992, KAIA is an association of Korean aerospace-related companies. In addition to developing the nation’s aerospace industry, the association is also responsible for related policy-making including budget recommendations.

The second Korean partner in the MoU, the IIACI, is a collaboration between national universities and industry specialists. Through certifications, training and internship programs, the institute promotes the growth of the aerospace industry in South Korea.

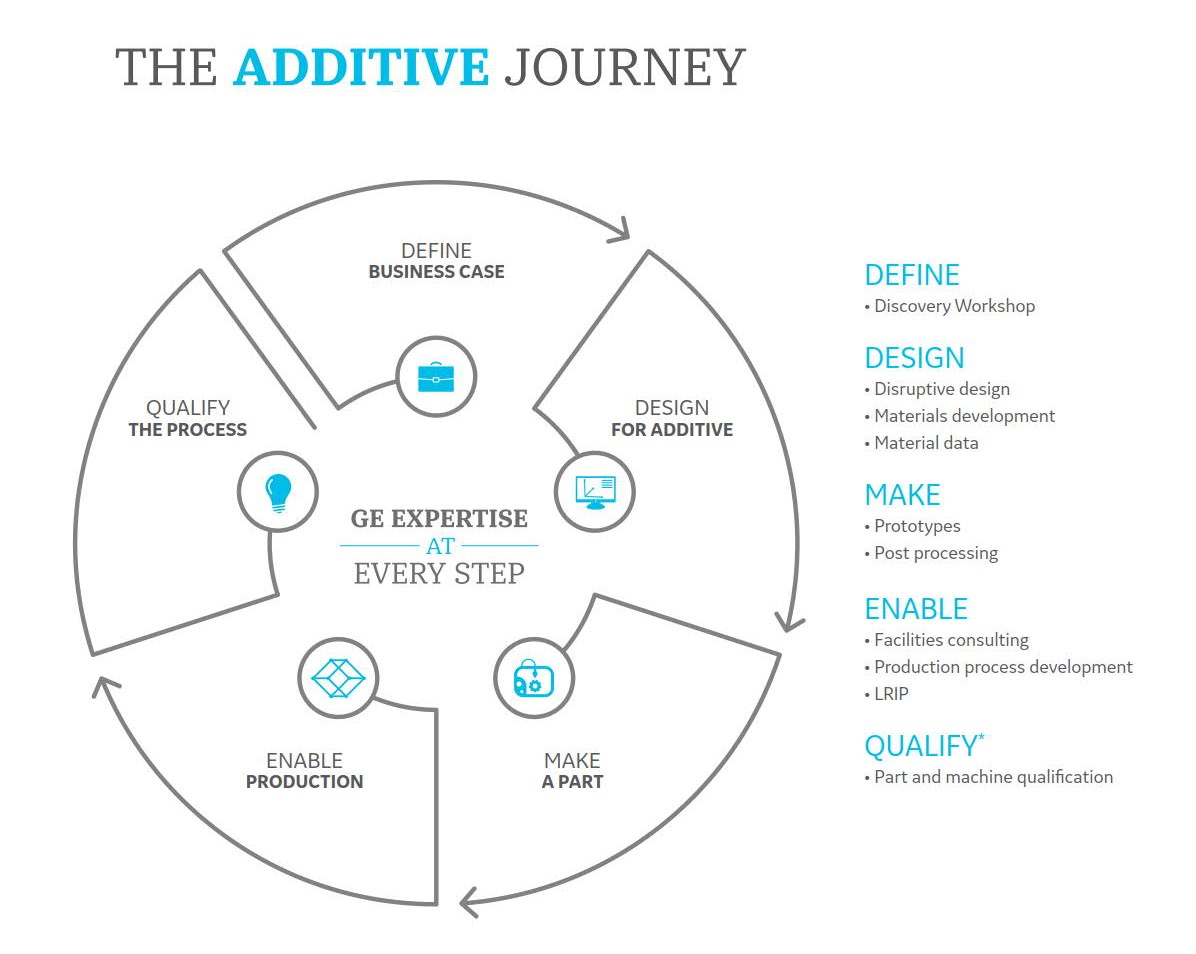

Under terms of the agreement, GE Additive will provide its AM consultation service package known as AddWorks. The consultation team of AddWorks provides the following step by step guide for industrial 3D printing:

– Define business case: defining AM, building a team, identifying funding opportunities

– Design for additive: training for AM design, conversion of designs, choosing the ideal materials and post-processing techniques

– Make a part: printing location, support structure recommendation, infrastructure for high volume 3D printing, certification

– Enable production: setting up a facility, scaling production, environmental, health, and safety (EHS) issues, material handling requirements

– Qualify the process: certifying the 3D printed parts, requirements of the target industry

GE Additive will also recommend the KAIA members for its Manufacturing Partner Network.

3D printing in South Korea

In recent years South Korea’s 3D printing industry has gained a boost from the government, and industry partners setting up facilities there.

Last year, South Korea’s Ministry of Science, ICT and Future Planning announced that it will spend $37 million USD to promote 3D printing across the country.

It was also reported that German 3D printer manufacturer, EOS and Z3DFAB, a South Korean metal 3D printing specialist, will build an AM facility in South Korea, to promote 3D printing services.

Subscribe to our 3D printing newsletter to receive news updates from the industry. Join us on Facebook and Twitter.

Our 3D printing job site is waiting for you to start an exciting career.

Featured image shows the KAI T-50 Golden Eagle, South Korea’s supersonic trainer and light combat aircraft. Image via KAIA