The Organ.Aut 3D bioprinter, tipped to be the first of its kind to make it aboard the International Space Station (ISS), has been incinerated in a failed launch of the Soyuz MS-10 spaceflight.

Luckily, both cosmonauts aboard the vehicle survived the accident in an emergency escape capsule, but the rest of the cargo disintegrated upon return to Earth.

3D Bioprinting Solutions, headquartered in Moscow, Russia, is the company behind the Organ.Aut system. According to Yousef Hesuani, the company’s co-founder and managing director:

“Organ.Aut and cosmonauts have a duplicate [of the printer], it will be ready to fly to the ISS in the near future,”

“The current crew has already confirmed its readiness for undergoing the remote training, so we will be ready to send the scientific equipment in any case.”

3D bioprinted thyroids and Fabion

3D Bioprinting Solutions is an arm of INVITRO, the largest private medical company in Russia. It was founded by Hesuani and INVITRO Chairman of the Board of Directors, Alexander Ostrovsky in 2013.

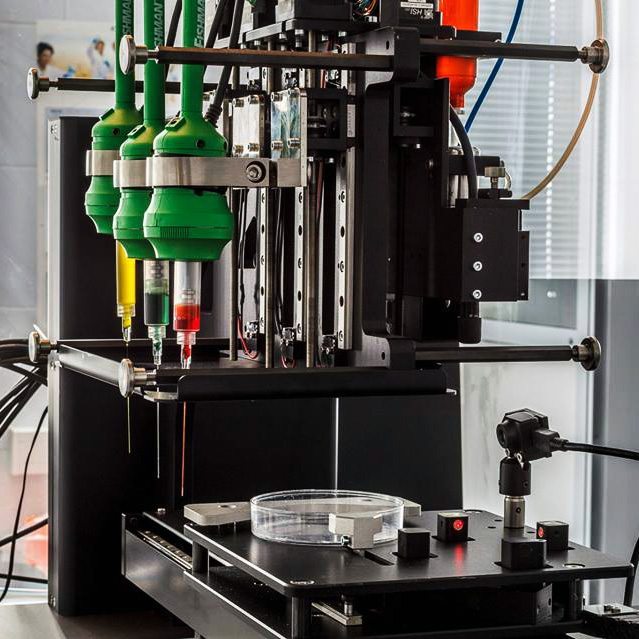

The following year, the company announced the successful development of its first 3D bioprinter, Fabion, believed by the team to be “one of the most multifunctional bioprinters in the world in terms of printing possibilities with different materials.”

Then, in 2015 Vladimir Mironov, 3D Bioprinting Solutions’ Head of Research, presented the successful implantation of a Fabion-printed mouse thyroid at the Biofabrication conference in Utrecht.

Working with spheroids

As shown in an demonstration video from 3D Bioprinting Solutions, Fabion, like the Kenzan method, seems to fabricate tissues from cell-containing spheroids.

The bioprinter relies on a gelatinous (possibly hydrogel) bed, to hold deposited spheres of biological matter in place. After each printed layer, the supportive gel is replenished to hold the next layer of spheres and so on until the desired shape is created.

When incubated, these cells fuse together, then gel is cleaned away leaving a sample of purely biological tissue.

Though little is known about the low-gravity Organ.Aut 3D bioprinter, it is likely that this system uses the same/similar technology as its predecessor, Fabion.

A 3D space race

The Soyuz MS-10 launch site, Baikonur Cosmodrome in Kazakhstan, will remain closed to any further launches until Roscosmos and NASA can pinpoint the cause of this flight’s failure. Though a necessary procedure, this delay could strip the Organ.Aut system of its title as “first 3D bioprinter aboard the ISS.”

The next 3D bioprinter scheduled for launch to the ISS is NASA’s 3D BioFabrication Facility (BFF) developed by nScrypt and Techshot. The BFF is scheduled for launch aboard the SpaceX CRS-17 commercial resupply service in February 2019.

In July 2018 Pennsylvania-headquartered Allevi and U.S. microgravity 3D printer developer Made In Space announced a partnership to develop the Allevi ZeroG – their answer to a low-gravity 3D bioprinter for the ISS.

Made In Space has had its initial Additive Manufacturing Facility (AMF) installed aboard the station station since 2014.

Keep up with the latest in additive manufacturing and aerospace by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or searching for new talent? Explore and post new 3D Printing Jobs for opportunities and talent across engineering, marketing, sales and more.

Featured image shows the ejected escape capsule of the failed Soyuz MS-10 spaceflight hurtling toward Earth. Photo by Bill Ingalls/NASA