Researchers at Kyoto University in Japan have successfully implanted 3D printed cells into the thighs of lab rats. The 3D bioprinting used is the Kenzan method, where cells are placed onto an arrangement of neatly packed needles and left to culture.

The Kenzan method

“Kenzan” is the Japanese word meaning “needle array”. The method has been commercialized by the Japanese 3D bioprinting corporation Cyfuse Biomedical K.K. in the Regenova 3D bioprinter.

The Regenova started developement in collaboration with plant systems and mechatronics developers Shibuya Kogyo Co. (TYO:6340) in August 2010. In September of the same year, the companies were commissioned by the Japanese New Energy and Industrial Technology Development Organization (NEDO) to start with cartilage research.

By December 2012, the collaboration had successfully developed the Kenzan method into the Regenova 3D bioprinter, and has since been looking into further applications for the technology.

Pick and place

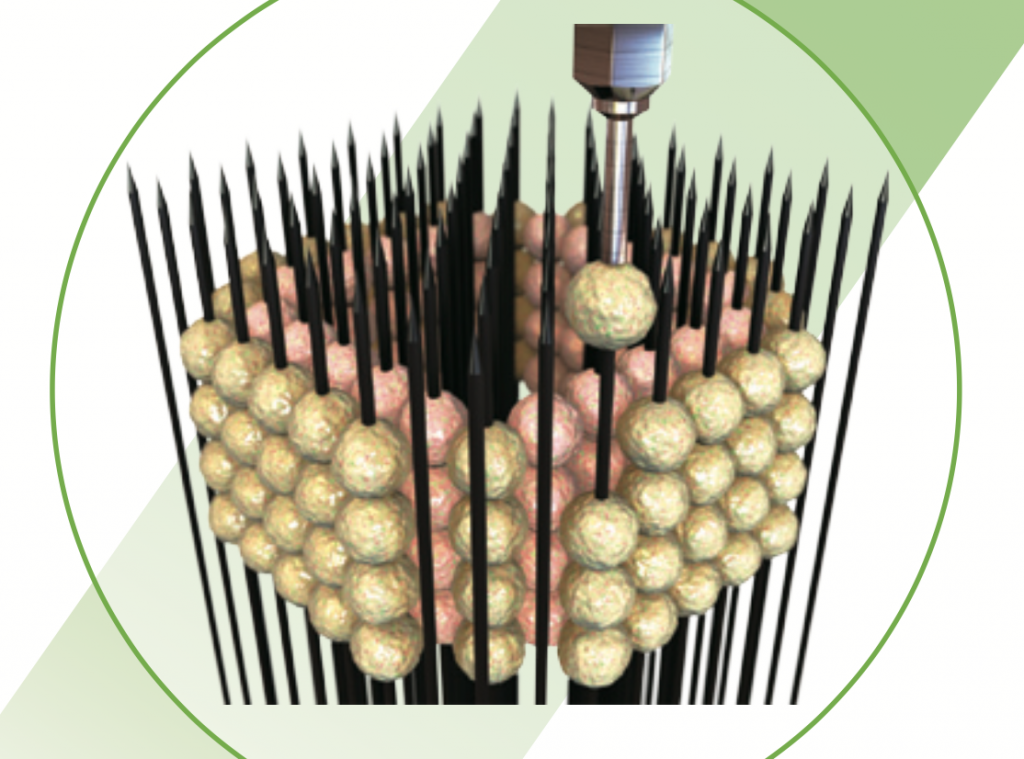

The Regenova uses live cells as feedstock. Rather than mixing these cells into a bioink to print as a hydrogel, the cells are cultured into 3D spheroids, so they can be suction-picked, and placed onto individual needles.

Placement of the cell spheroids in the Regenova. Clip via Cyfuse Biomedical on YouTube

Placement is simply designed by a CAD platform, and by selecting the correct needle array attachment: either 9×9 needles in a square or a tubular construct, or 26×26.

Design of the desired cell placement. Clip via Cyfuse Biomedical on YouTube

After 3D printing, the spheroid cells are left to form bonds for a few days. Once fused they are removed from the needles, showing holes only where the have been skewered.

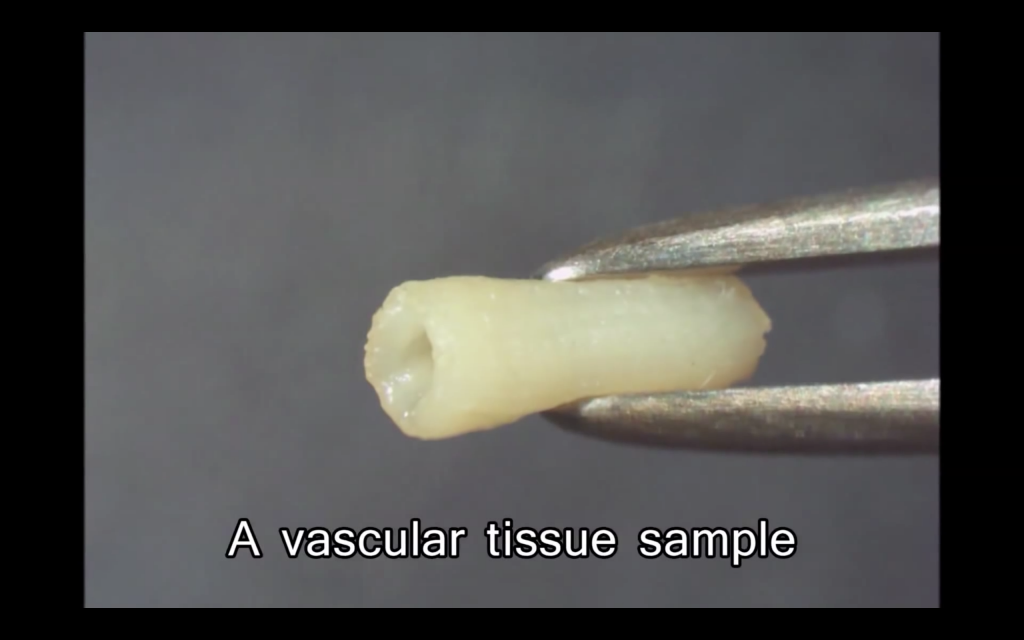

These delicate structures are then left to mature in a bioreactor and fill the needle holes. Inside this bioreactor, the cells perform the natural process of “sorting out”, where they group together with cells of their own type and form a vessel matching the kind found in the body.

Living transplants

In the human body, permanent damage to the nerves is typically irreversible. In the rats at the University of Kyoto however, a removed section of a thigh nerve was able to grow back using tubular constructs.

Half of the rats were transplanted with a silicone tube to promote nerve regeneration, and the other half received the 3D bioprinted tissue vessel. By comparison, the bio printed tissue promoted faster regrowth of the nerve within the rats, providing a promising result for continued R&D.

In China, the National High Tech Research and Development Program similarly performed the successful implant of vascular tissue into 30 living rhesus macaque monkeys. By contrast, this process used the Revotek-T series of 3D bioprinters to produce the vessel, which works using a rotating steel bar.

Organovo are also a key player in the 3D bioprinting market, and have released results showing positive development of microscopic kidney vessels.

Vascular tissue is the base goal for any companies and researchers currently looking into the possibilities of 3D bioprinting. Now that this seems to be possible, pre-clinical trial implants are the next step for the technology which, with the body’s strong immune system, will be no easy task.

To stay up to date with 3D bioprinting research, you can sign up to the 3D Printing Industry newsletter, and follow us on our social media channels.

Featured image shows the Regonova 3D bioprinter selecting a spheroid to place on Kenzan needles. Photo via Cyfuse Biomedical K.K.