In 3D bioprinting research, developing functional vessels is a vital task. Harvard are gradually building up kidneys from the tubule level, and Northeastern are studying the vascular properties of 3D printed veins, and numerous other institutions are developing their own 3D bioprinters for this purpose. Other research is based around 3D printers such as the Revotek-T series, a 3D blood vessel bio-printer first released in 2015. The 3D printer has been most recently used by the Chinese National High Tech Research and Development Program (also known as the 863 Program), where researchers have now successfully implanted a 3D printed blood vessel into 30 living rhesus macaque monkeys.

The institutions involved

The 863 Program was set up by China’s Ministry of Science and Technology (MoST) in 1986 to accelerate the nation’s plan to become a world leader in scientific research. Almost $2 billion went into funding research projects during 2009, with a call for new applications released in 2012 and offering support for a maximum of 5 years.

Revotek is a subdivision of the Chinese Sichuan Languang Development Co. The company’s primary focus is the manufacture and development of medicines. Revotek’s headquarters are in Sichuan, a southwestern province of China, where the company are developing area of stem cell research.

How did they do it?

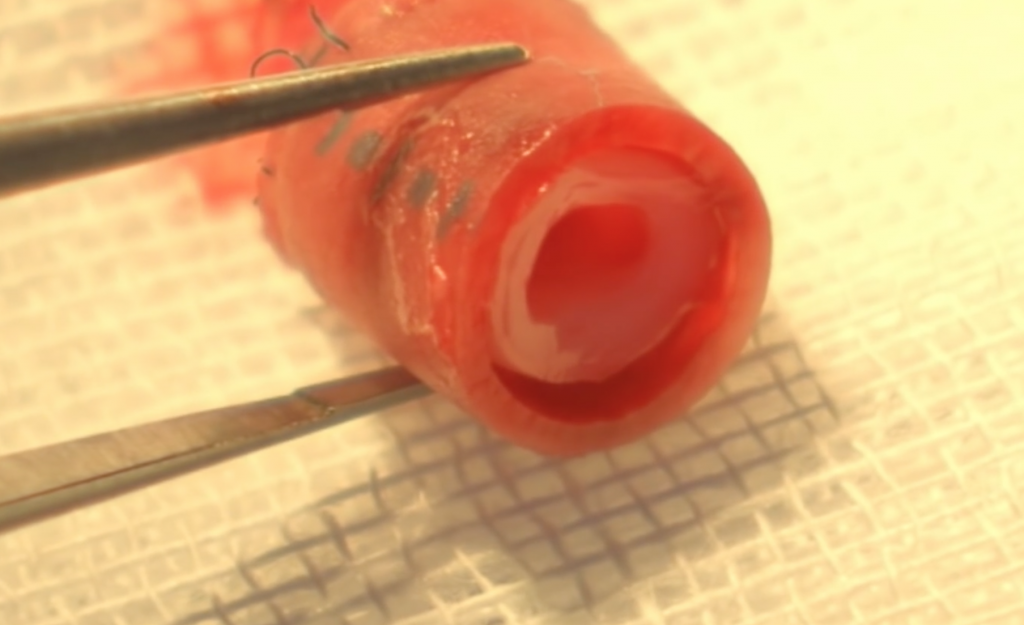

Revotek’s T series 3D bioprinter operates by extruding layers of stem cells and nutrients onto a rotating bar (called a Rollavesseler) coated in a preservative scaffold material.

A graphic representation of how a Revotek-T series 3D blood vessel bio-printer extrudes cells. Image via: CCTV+ on Youtube

The cylinder of cells is then covered in a sleeve to ensure they retain their shape while cultured in a controlled environment. While the research does not specify the precise method, it is reasonable to speculate that these conditions may involve imitation physiological processes such as subjecting the cells to blood-flow. Maturing under such conditions encourages the stem cells to become a particular tissue in a process referred to as sorting-out.

The vessel transplants were then made to the macaques’ abdominal aortas (the largest artery in the lower part of a primate’s torso) and in each of the 30 cases were found to be fully functional after the operation.

CT imaging of the 3D printed blood vessel beating with blood flow inside a monkey. Image via: CCTV+ on Youtube

The legacy

Speaking to CCTV (China Central Television) Kang Yujian, a leading scientist at Revotek, explains how the monkey’s native cells would eventually take over the synthetic structure,

Within five days, the endoderm will come out, so will the smooth muscle layer. In 28 days, all cell tissue will develop. The section we transplanted has no differences from the original. It has become a real blood vessel. This is unprecedented.

To encourage the advancement of science, Revotek say that they plan to share the findings so other institutions can pick up on their work. Although this has not yet taken place, this is an important decision and will likely advance the production of 3D bioprinting and organ fabrication.

Featured image shows rhesus macaque monkeys photo by: cattan2011 on Flickr