New research describes how a team, “developed and implanted .. the world’s first” custom 3D printed airway stent.

The work is a collaboration between Toulouse University Hospital’s Pulmonology department and local start-up AnatomikModeling. The results of the study are published in the American Journal of Respiratory and Critical Care Medicine and describe the first findings from a clinical trial.

The 3D printing advantage

Customized stents are advantageous as they can be made, “anatomically identical to patients’ trachea and/or bronchi.” This means that the group of patients who are currently unable to use standard prostheses now have an alternative.

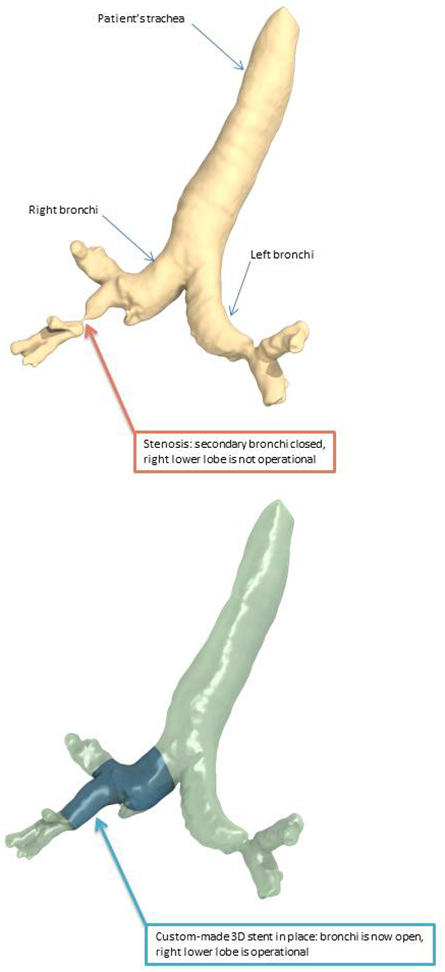

Lung cancer patients are one group who may benefit from this work. Specifically, this group can experience blockage of the upper airways or narrowing of the bronchi or trachea. This increases patient distress and discomfort: the condition is known as stenosis.

Traditional methods for the treatment of stenosis involve the surgical implant of stents, these stents come in a range of sizes but are far from suitable for every patient. For example, a patient may have, “complex tracheal or bronchial anatomy.” Ill-fitting stents can lead to further complications including infection, inflammation and even perforation.

3D printing the stents allows for customization and may overcome these issues. AnatomikModeling explain how the process works,

These new prostheses are custom-made in three steps: first, a 3D reconstruction of the patient’s airways is produced from CT-scan images. This virtual reconstruction is then used to create a mold. Finally, a patient-specific prosthesis is manufactured from medical grade silicone elastomer.

The prosthesis is implanted by conventional bronchoscopy with the help of a prosthesis pusher, in the operating room under general anesthesia. In addition, the rigidity of the stent can be calculated as a function of the stenosis.

This new technology is being evaluated in an ongoing clinical trial. Through this, several patients have successfully received these implants, resulting in markedly improved quality of life with no complications so far.

Research into 3D printing for regenerative medicine

Tubular structures are common throughout the body and replicating these while tailoring implants to specific patient anatomy is area where 3D printing has received considerable attention.

Work at Northwestern University used a citrus based polymer to 3D print biodegradable vascular stents. The Northwestern researchers used SLA 3D printing in a process termed micro continuous liquid interface production (microCLIP) to create stents for the treatment of weakened or narrowed arteries.

In the UK, research looking at “smart, functionalized synthetic materials [that] can act as a scaffold,” is also underway. More recent research published in the February 2017 edition of the Journal of Materials Science looks at other applications of 3D printing for regenerative medicine.

The research from a team led by corresponding author Achala de Mel addresses the need for, “biomimetic materials that can be used as tissue substitutes or medical devices that can address damaged and diseased tissue.” An avenue proposed for further investigation is, “3D printed scaffolds thus imparting biofunctionality and surface topography.”

For all the latest news about 3D printing for medical applications, subscribe to our newsletter and follow 3D Printing Industry on social media.