This was may day so far: I wrote about an amazing new development in the adoption of 3D printing for surgery in Italy, an incredible new 3D printing technology developed by a graduate student in Buffalo, and a stunning “smart doll” created by a self-described gaijin (non-Japanese person) in Japan. Only a couple of years ago, this would be science fiction. Instead, to top it off, here I am enjoying the sunset with a Campari Spritz, writing about my interview with Vladimir Mironov, the scientist behind most of the work at Russia’s 3D Bioprinting Solutions (3D Bio for short).

The Skolkovo-based start-up has been extremely outspoken (some would even say too outspoken) about its intentions of creating a functional, 3D printed, complex organ for implant in humans. So far, 3D Bio has been delivering on all of its promises and made further headlines last week when they announced the first functional bioprinted thyroid for implantation in mice.

All of my relatives that work in the medical or scientific field are very quick to “crush” my arguments when I ask them about the possibility of 3D printing functional organs, saying that there is no way to replicate an organ’s complex, multicellular structure. I consider these relatives to be extremely knowledgeable and reliable, but they are mostly doctors and/or researchers who are not directly familiar with additive manufacturing technologies.

On the other hand, 3D Bioprinting Solution’s enthusiasm, as with any other 3D bioprinting venture, is contagious and I know from experience that, with 3D printing nothing is impossible, and nothing can be entirely discarded. The truth probably lies somewhere in the middle: bioprinting complex organs is an extremely difficult feat to achieve, but, sooner or later, it will be done. And 3D Bioprinting Solutions may be the company to do it.

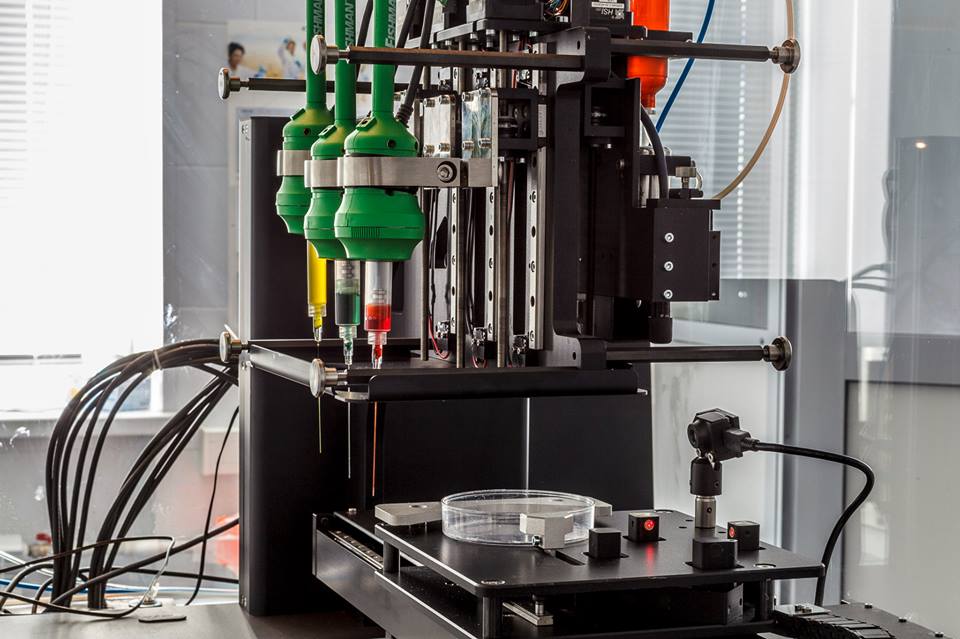

“You may recall that the first step in our journey was the opening of the laboratory, achieved with the financial support of the company INVITRO,” Alexander Ostrovsky, General Director of 3D Bioprinting Solutions, said, at the time. “The birth of bioprinting in Russia occurred in the beginning of 2013, with the creation of 3D Bioprinting Solutions and it was stated that the company would create its own original bioprinted within one year. The company kept its word. Subsequently, at the launch event for this first Russian bioprinter we made what sounded like an even more sensational statement. We promised that by the spring of 2015 we would have within the walls of this laboratory a bioprinted organ construct thyroid gland.”

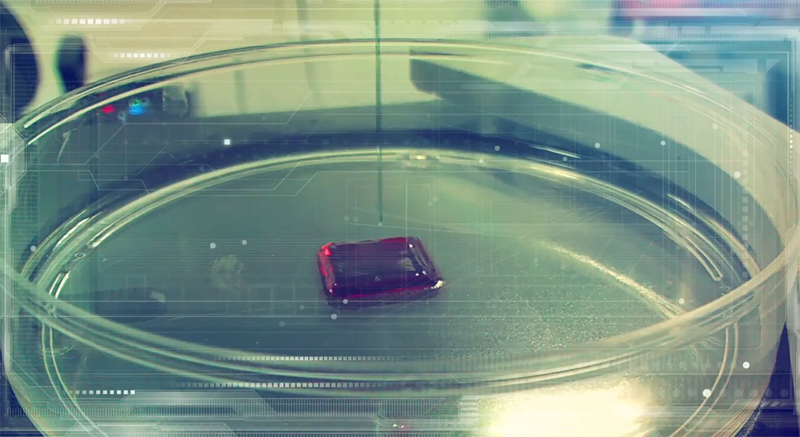

3D Bio will concede that the resulting construct cannot be defined as an organ in the traditional sense. “There is a definite classification of the structural organization of hierarchical levels of living,” Vladimir Mironov explained. “Ascending this hierarchy, then we have firstly the molecule, then the cell, the tissue, organs, organ systems and finally, the body. If you take this system for granted, then, on that basis, the entity we have bioprinted has no place in the classification. Therefore, we decided to call it an organ construct. Why did we do that? Again, observe the makeup of tissues – they are a collection of cells of one type. An organ is a collection of tissues. We created something that is much closer to the organ than to the tissue, because it consists of several types of tissues, is vascularized (contains a blood vessel network) and functions at the level of an organ. Our bioprinted mouse’s thyroid gland organ construct is also much more complex than the so-called organic tissue-like structures or organelles that have previously been created, since these do not have vascularization before their implantation into an organism. This is a fundamentally important difference.”

The vascularization, Mironov told me, was obtained by using embryonic thyroid gland explants which were already pre-vascularized. “Additionally,” he said, “we generated inlet and outlet vessels using tissue fusion of lumenized vascular tissue spheroids.” To find out about this process you can view the video below, recently released by 3D Bio. In case you’re familiar with bioprinting research, the process they implemented is not related to the work done at Harvard’s Lewis Lab. Mironov cited Christofer Chen from University of Pennsylvania and Sangeeta Bhatia from MIT, as leading pioneers in this field.

So, what are the prospect from here on for 3D Bio? That is exactly what I set out to find out and Julia Smirnova, 3D Bio’s extremely active Marketing Director, was happy to oblige. The company’s strategy is driven by two importance concepts and both are very exciting. Whether they will correspond to actual achievements remains to be seen; however, there are no great leaps forward in science without someone making a radical jump away from traditional approaches.

Elena Bulanova, head of cell technology research laboratory at 3D Bioprinting Solutions said that the team is already working on the second stage of the research: evaluation of the functionality of the printed mouse thyroid gland construct. “During one month, we will observe if the original thyroid gland really stops functioning. We will then analyze thyroxine production, as it must decrease dramatically after suppressing the thyroid’s functions,” she said. “Then we will implant our construct. It is planned for use in a total of 12 animals: 6 control mice with no implant and 6 mice with a construct implant. We will give 1 month for the implant to survive and start functioning. We will implant the [thyroid construct] under renal capsule to avoid immune response issues. In a month after implantation, we will test the thyroxine levels; they should be back to normal. This way, the printed construct will functionally completely replace the original thyroid gland of the mouse.”

If that yields positive results, it will be time to consider human testing. 3D Bio intends to start working on bioassembling a human thyroid organoid as soon as they receive the functional human thyroid epithelial cells generated by their collaborators, using human IPC cells. And, since we were venturing into the realm of possibilities, I also asked what would come next. Mironov did not hesitate to say that the next challenge would be another human organ “according to [their] company internal plan.” The long-term objective is already public: bioprinting a human kidney. “Sooner or later, the sooner the better, of course”, Mironov said.

He truly believes that this is possible and not only the bioprinting of kidneys. Prof. Takebe from Yokohama City University in Japan, he says, intends to generate a human liver and transplant the organ into a human by 2019. The major goals to reach, as explained by Prof Takebe, are obtaining a sufficient amount of clinically relevant therapeutic grade cells, the creation of scalable automated and robotised GMP (Good Manufacturing Practices) facilities, and a high percentage of successful engraftment (vascularization, viability, and so on). The heart is also on the list, and the leading expert working on this task is Dr. Stuart Williams, of the University of Louisville Cardiovascular Innovation Institute. As Mironov clearly states, if scientists abandon the idea that they need a polymer scaffold to on which to bioprint the tissues, then “everything is bioprintable”.

At this point, to ask the doctor about cartilaginous structures seemed almost anti-climactic. However, Dr. Mironov also mentioned several studies underway in this area, as well as the printing of pancreatic cells, which would possibly provide a way to cure diabetes down the line. “Prof. Douglas Melton from Harvard University is an expert in insulin producing docile pancreatic cells,” he said. “He claimed that he has already developed a protocol for the generation of beta cell endocrine cells producing insulin from human IPC cells. I believe,” Mironov concluded, “that we will observe some results in this field it in the nearest future.”

I really want to believe everything Dr. Mironov says and the confidence with which he says it makes it all so much easier. As you can guess, this is one story that we are definitely going to follow-up on.