Lufthansa Technik, the maintenance, repair, and overhaul (MRO) division of aerospace company Lufthansa, has established a new Additive Manufacturing Center in Germany to develop lightweight aircraft parts.

“The new AM Center will serve as a collaborative hub where the experience and skills that Lufthansa Technik has gained in additive manufacturing can be bundled and further expanded. The aim is to increase the degree of maturity of the technologies and to develop products that are suitable for production,” said Dr. Aenne Koester, Head of the AM Center.

Lufthansa Technik and additive manufacturing

Recognizing the accelerating industrialization of additive manufacturing, a joint team of Lufthansa Technik experts and 3D printing specialists have collaborated to leverage the design freedom and rapid prototyping capabilities of its technologies to produce aircraft components.

Thus, this center will help drive additive manufacturing forward with customizable 3D printed aerospace parts. Furthermore, through the manufacturing process, researchers will explore defining standards for the qualification and approval of aircraft components. “In the highly weight-conscious world of aircraft, the lower weight of parts makes using AM technology very attractive,” stated Lufthansa Technik.

Earlier this year, Lufthansa Technik, joined Swiss technology group Oerlikon in establishing standard additive manufacturing practice for the aerospace industry. This partnership also aims to understand process repeatability, a key element of industrialization and certification. Dr. Roland Fischer, CEO, Oerlikon Group stated:

“Oerlikon’s extensive expertise in additive manufacturing and the aerospace industry, combined with our proven ability to integrate solutions throughout the manufacturing value chain on a global scale will bring great benefits to Lufthansa Technik.”

Prior to this, Lufthansa Technik, invested in EOSTATE MeltPool, an extension for EOS M 290 system for Direct Metal Laser Sintering (DMLS) which provides automated and intelligent process monitoring during the additive manufacturing processes.

Keep up with the latest in additive manufacturing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or searching for new talent? Explore and post new 3D Printing Jobs for opportunities and talent across engineering, marketing, sales and more.

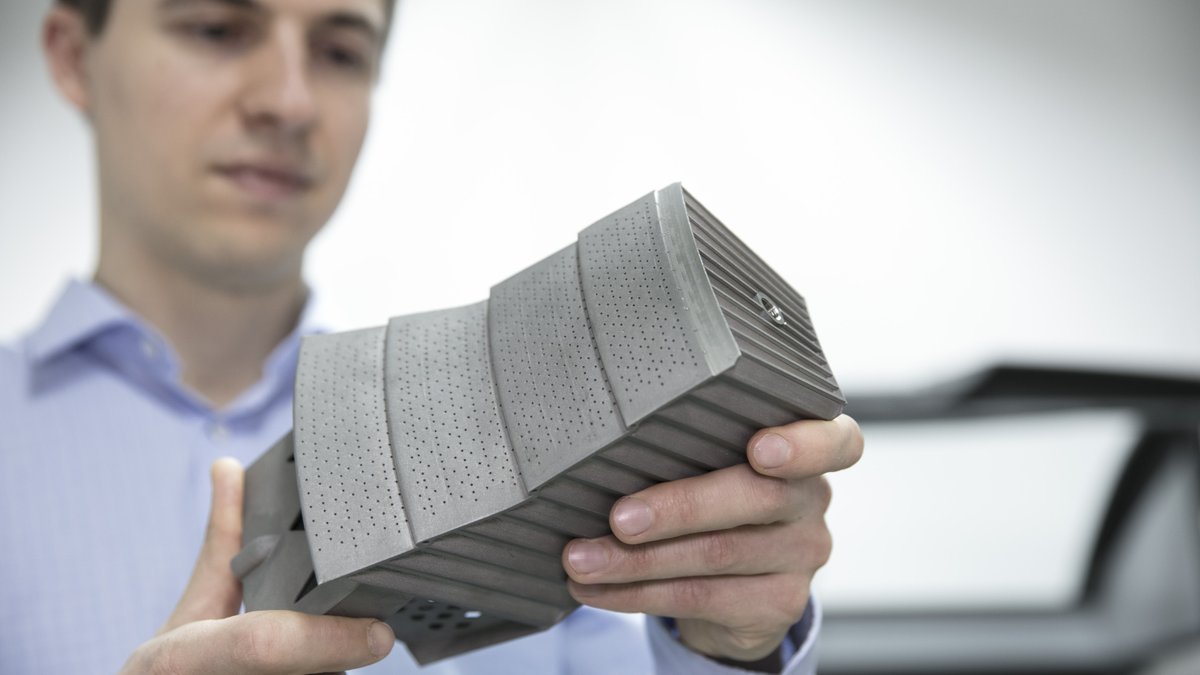

Featured image shows a 3D printed aerospace component. Photo via Lufthansa Technik.