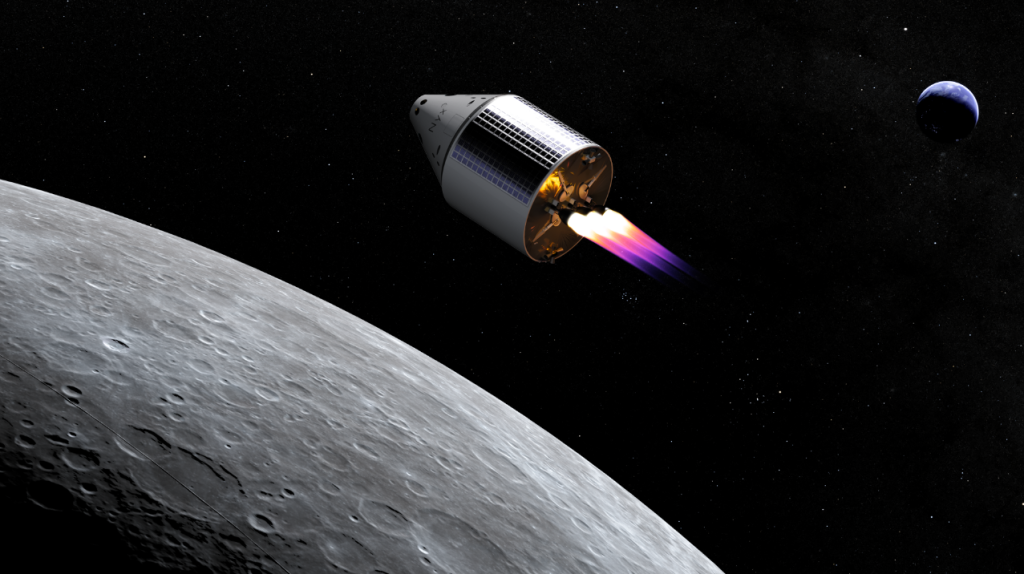

German technology company TRUMPF and European space travel start-up The Exploration Company have partnered to manufacture core components for spacecraft for missions in the Earth’s orbit and to the moon.

The focus of this collaboration is on utilizing TRUMPF’s 3D printing technology to produce components for the Huracán and Mistral engines of the Nyx Earth and Nyx Moon spacecraft. The production is set to commence in spring 2024 at Planegg, Germany, near Munich, as part of the TRUMPF and The Exploration Company collaboration. The start-up has outlined its mission objectives, with plans to send a space capsule for an initial Earth orbit mission in 2026. Looking ahead to 2028, further missions are on the agenda, this time targeting the moon. While the spacecraft will initially focus on transporting freight, there are long-term aspirations for human space travel onboard.

“Our aim is to offer space missions more cost-effectively than was previously possible. Our spacecraft can benefit from TRUMPF’s manufacturing and application expertise. TRUMPF has decades of experience in the production of high-precision components,” says Hélène Huby, CEO of The Exploration Company.

AM takes on a front-row seat in aerospace advancements

Additive manufacturing allows designers to consolidate entire assemblies into single components, reducing weight, complexity, and, subsequently, fuel costs. The streamlined components also contribute to lower safety testing expenses before rocket launches, enhancing the likelihood of successful space missions.

A few days ago, Chinese aerospace firm Orienspace‘s Gravity-1 Y-1 commercial carrier rocket, deemed the “world’s largest solid rocket,” utilized Bright Laser Technologies‘ (BLT) Laser Solid Forming (LSF) 3D printing for structural components with complex geometries.

BLT’s technology achieved rapid, high-quality production, reducing costs and development time. Over 30 components, including TC11 titanium alloy parts, were successfully 3D printed, meeting the stringent requirements for the rocket’s commercial launch on January 11, with reduced production cycles and costs reported.

CRP Technology collaborated with UAE’s Orbital Space for the Lunar Exploration mission, utilizing advanced 3D printing through the Powder Bed Fusion (PBF) process. This move was aimed at the production of 3D printed functional components for the lunar payload using Windform‘s high-performance composite materials, ensuring compliance with stringent mechanical properties for space applications. CRP Technology’s industrial 3D printing service supplied crucial components for Orbital Space’s past Lunaris Moon Mission, dedicated to lunar exploration.

TRUMPF’s additive manufacturing endeavors

Considering bio-methane and oxygen as propellants, TRUMPF’s partnership with The Exploration Company aims to improve the Huracán engine’s reusability and refuelability in orbit. Securing €65 million from a combination of private and public investors, The Exploration Company operates with approximately 120 employees spread across its facilities in Planegg, Germany, and Bordeaux, France. Last year, experts predicted significant growth in the global market for aircraft and spacecraft production, projecting it to reach €740 billion, says the company.

“With our 3D printing technology, we are driving the commercialization of the space travel industry. If you want to be successful in the space travel industry today, you have to use additive manufacturing,” added Tobias Brune of TRUMPF.

Beyond financial factors, the collaboration underscores environmental advantages. The Exploration Company benefits from 3D printing in optimizing raw material use, utilizing only what’s intended for space. In contrast, conventional aerospace manufacturing methods frequently yield considerable material waste.

Over the years, TRUMPF made headlines in advancing 3D printing by collaborating with various entities. In 2022, The Fraunhofer Institute for Laser Technology (ILT) and TRUMPF joined forces to advance laser metal deposition technology. Focused on improving productivity, speed, and materials, this venture utilized TRUMPF’s laser system proficiency, notably in Extreme High-Speed Laser Material Deposition (EHLA) 3D printing.

TRUMPF’s diverse 3D printing portfolio, including the TruPrint and TruLaser Cell series, supports research on industrially relevant systems. Envisaged applications included cost-effective brake disc coating and heightened wear protection for hydraulic cylinders, with plans for broader cooperation in laser materials processing.

Back in 2020, performance sports car manufacturer Porsche collaborated with TRUMPF and MAHLE to 3D print pistons for its 911 supercar, utilizing Laser Metal Fusion (LMF) technology. The AI-led additive manufacturing optimized the piston structure under load, reducing weight by 10% and adding 30 BHP to the 3.8-liter twin-turbo engine.

Focused material use in high-stress areas made the pistons lighter than conventional ones. Incorporating a cooling duct and AI optimization minimized supporting material, with six prototypes produced using in-house aluminum alloy powder. Taking 12 hours, the process involved laser melting 3D printing and traditional preparatory steps.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows The Exploration Company uses 3D printers from TRUMPF to produce core components for the propulsion systems of its spacecraft. Photo via The Exploration Company.