Will 3D printing replace mass production methods? Most experts agree that additive manufacturing is a complement, rather than a direct competitor for techniques such as injection molding or CNC machining.

3D printing for low volume batch production is increasingly an option to bring a product to market, and analysis of trends in additive manufacturing for end use production estimate approximately one-third of 3D printers are used for production.

Here are some of the recent uses of 3D printing for production.

Adidas and Carbon: 3D printed sneakers

In April 2017 the German footwear giant adidas announced a line of 3D printed shoes, called Futurecraft 4D. Production of the 3D printed sneakers is done using, “digital light synthesis” – a photopolymerisation method – from California-based Carbon.

According to Carbon, adidas has a “current [production] target [of] 100k by 2018 and ultimately true mass production as things scale up, aka 10s of millions.”

When the first batch of 3D printed Futurecraft 4D shoes was released on January 18th, 2018 demand outpaced supply and resale prices for the adidas Futurecraft reached $20,000.

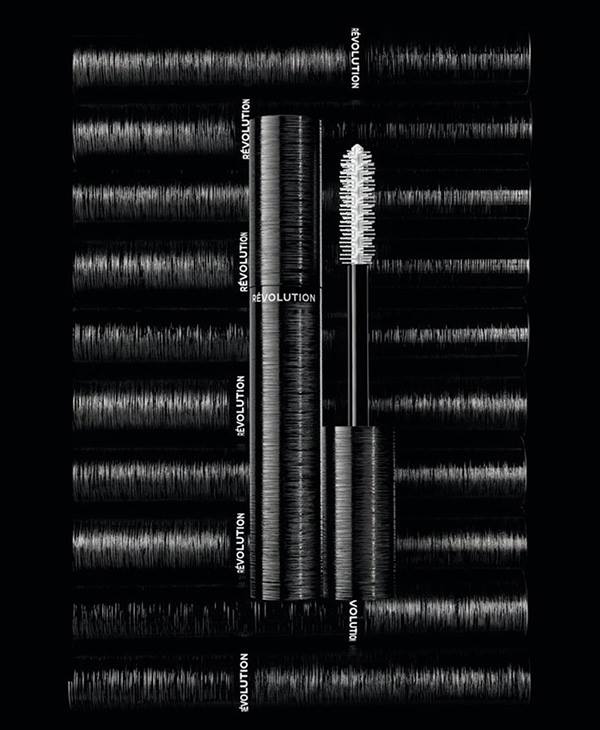

Chanel and Erpro Group: 3D printed make-up brushes

French fashion brand Chanel announced production of the first entirely 3D printed mascara brushes would begin in June 2018. With a patent originally filed in 2007 and in partnership with Parisian 3D printing bureau Erpro Group, 3D printed production of 1 million brushes a month is the target.

The Chanel design allows a higher volume of mascara to be loaded onto the make-up brush. 3D printing is used to create microcavities in the core of the brush, and also enhance its adhesion to eyelashes thanks to a larger surface area.

Align Technology: digital dentistry and 3D printed aligners

Align Technology Inc, a company boasting 3D printing farm with over 60 additive manufacturing systems, has set out to revolutionise dental care, combining 3D technology with dentistry to produce 8 million orthodontics a year.

Approved by the US Food and Drug Agency since 1998 and using bio-compatible polyurethane resin, the Invisalign process enables dentists to convert scans of the oral cavity into digital files, which are then used to 3D print and manufacture the customised orthodontics.

Optomec and LITE-ON: 3D printed smartphones

While 3D printing phone cases is no rare phenomenon, New Mexico company Opotomec started applying additive manufacturing technology to mass production in 2016.

The company uses a hybrid approach, combining 3D printing with subtractive techniques such as CNC milling. According to Ken Vartanian at Optomec, “A large percentage of the electronics in a smartphone can be manufactured with additive manufacturing”, while CNC milling facilitates the surface polish.

Stratasys and Airbus: 3D printed aerospace components

In May 2015, Minnesota-based 3D printing company Stratasys revealed that it had produced over 1000 parts for the Airbus A350 XWB passenger plane. According to Stratasys, one of the great appeals of 3D printing technology is the flexibility it affords aircraft manufacturers, helping them meet production deadlines.

According to Dan Yalon at Stratasys, 3D printing also increases the buy-to-fly ratio and results in an amount of wasted material that is considerably lesser than with traditional manufacturing processes.

While it remains too early to declare whether 3D printing can replace traditional manufacturing methods, the potential of innovation shown by additive manufacturing compared to injection molding or CNC machining is already evident, and we at 3D Printing Industry look forward to seeing how 3D printing continues to impact mass production.

You can read more about trends in 3D printing for mass production here.

Keep up to date with the latest 3D printing news. Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Vote for the software the year in the 2018 3D Printing Industry Awards.

Featured image shows 3D Design company Cunicode’s “30 days, 30 cups” projects. Image via Cunicode.