Trends in additive manufacturing for end-use production was a recent in-depth look at what some see as the the next phase of 3D printing.

3D printed sneakers, custom-fit insoles, clothing and toys – commercial 3D printing – are often the subject of hype surrounding 3D printing’s integration into the supply chain. There are many big names behind these projects, for example adidas and Carbon of Futurecraft 4D sneakers, Formlabs and New Balance, EOS and Under Armour. However, the making of 3D printing for series-level manufacturing will, in many ways, be shaped by its adoption in China and the surrounding countries – the global center of mass production.

The Impact of 3D Printing Technology on Supply Chain in China is considered in a new report by H.K. Chan, J. Griffin, J.J. Lim, F. Zeng and A.S.F. Chiu, of the University of Nottingham Ningbo China, the University of Exeter in the UK, and De La Salle University in the Philippines.

“If we have started a new industrial revolution (inter alia digital manufacturing, Industry 4.0), [3D printing] is definitely part of it and is considered as a game changer,” states the introduction.

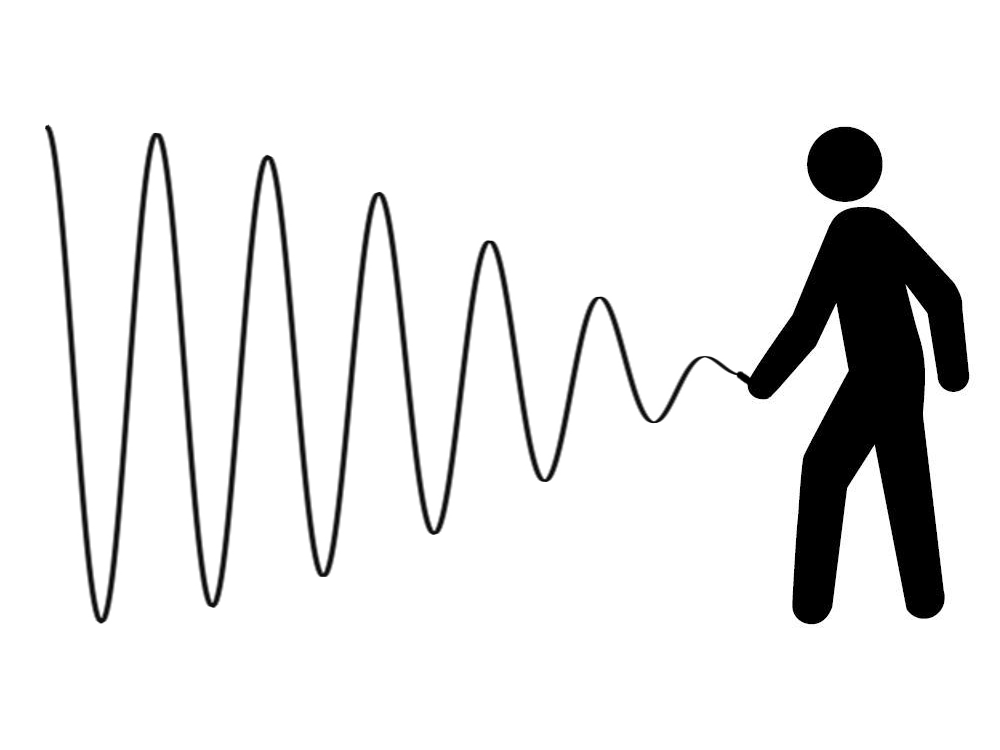

“With 3DP production can be started on a made-to-order basis. […] In other words, the excessive inventory stocking up due to uncertain demand along a supply chain, known as the famous Bullwhip Effect, should accordingly be reduced.”

Breaking the Bullwhip Effect

The chief contemplation of Chiu et al.’s paper is 3D printing’s part in helping to reduce the “Bullwhip Effect.”

The Bullwhip Effect describes a phenomenon in which manufacturers build a huge inventory of products based on a forecast of customer demand. From the assumed position high on the supply chain, a manufacturer can misinterpret consumer purchasing behaviour at retail level – resulting in a mass of unsaleable stock.

Mass customization, i.e. making products to exact customer specifications, low-labor demands and product consolidation, gives 3D printing the potential to break-free of the Bullwhip Effect, therefore leading to the question:

“If the Bullwhip Effect is a critical problem in any supply chain, would 3DP be the solution?”

A technology with impact

A comprehensive review of the implications of 3D printing for the supply chain was discussed by Rogers et al. in a paper for International Journal of Physical

Distribution & Logistics Management published in 2016. This study is used by Chiu et al. as a basis for their report.

To address 3D printing’s current impact on the supply chain, the team interviewed 28 general and technical managers of 3D printing businesses in China. Names and respective companies remain undisclosed, however each interviewee is in one of four areas:

- Chinese 3D printer manufacturer and distributor of foreign brands

- 3D printing and scanning software supplier

- 3D printing material supplier and material [development] institution, or,

- A 3D printing solution provider, e.g. bureau or similar.

It remains a flaw of the study however that the researchers do not focus on a specific industry, i.e. aerospace, automotive, medical, which gives potential for development.

Findings are respectively sorted into general comments of three areas of 3D printing: R&D and Design; Manufacturing and Supply Chain; and Data Management.

Keeping promises

In general, 3D printing fulfils the respective categories by feeding the concept of a supply chain-free utopia.

In R&D, interview data dictates that “it is easier to produce a new product in smaller quantity with relatively affordable capital with 3DP technology.”

Additionally, “Companies can then move from Original Equipment Manufacturing (OEM) or contract manufacturing to Original Design Manufacturing (ODM) with the assistance of 3DP. This is exactly what the ‘Made-in-China 2025’ initiative would like to achieve in China.”

For Manufacturing and Supply Chain, the interviewees cite the concept of mass customization, which would require a new supply chain paradigm. In this mode, “Manufacturers do not need to stock up different types of materials but the materials for 3DP, which can be used to produce different types of parts and products. Effectively, there is no need to manage the supply chain in this sense.”

And finally, better Big Data management theoretically helps product traceability, and encourages multi-department collaboration and customization for little effort to the designers.

The era of mass customization?

In summary, the report states, “It is still too early to conclude that the mass production era has been replaced by the mass customisation era.”

“In fact,” the conclusion continues, “the opposite is probably more accurate according to the interviews,”

“3D printing has created a lot of “hopes” but at this stage 3D printing has still not fully delivered its promise.”

However, the authors do state that the 3D printing, and other related technologies, are creating the necessary transition for this new era, where traditional manufacturing and mass customization will work hand-in-hand.

You can read more about trends in 3D printing for mass production here.

Stay ahead of the curve by subscribing to the free 3D Printing Industry newsletter, following us on Twitter, and liking us on Facebook.

Nominate the best 3D printing research teams in the 2018 3D Printing Industry Awards.

Featured image shows a photo of the Oriental Pearl Tower in the center of Shanghai – a hub for tech developments in China. Photo by sama093/Flickr