Famous French fashion brand Chanel is to begin industrial production of an entirely 3D printed mascara brush. When it makes it to market, the 3D printed brush will be the first of its kind to be manufactured on an industrial scale.

The Volume Révolution mascara brush was made in collaboration with Erpro Group. Erpro Group, based on the outskirts of Paris, France, are a 3D printing service provider with a range of 3D printers and expertise in technologies such as ABS wire deposition, 3D scanning and SLA, SLS, SLM printing.

A patent for a 3D printed mascara brush was first filed by Chanel in 2007, so it seems over 10 years of R&D has gone into the production of this everyday makeup applicator.

Brush hour 3D printing

Six industrial 3D printers will begin manufacture of the brushes in June 2018. The 3D printers are reportedly capable of producing up to 50,000 brushes a day, up to a target of of 1 million brushes a month.

The 3D printers use selective laser sintering (SLS) to manufacture the brushes by “printing successive layers of a polyamide powder polymerized with a laser beam.” Chanel says the process is protected by several patents but did not mention how the process differs from common SLS technology.

The next generation in makeup application

3D printing will be used for manufacturing, but has also been used in the design process of the brush. 3D printing allowed designers to eschew the traditional mold creation process, which is often time consuming and expensive.

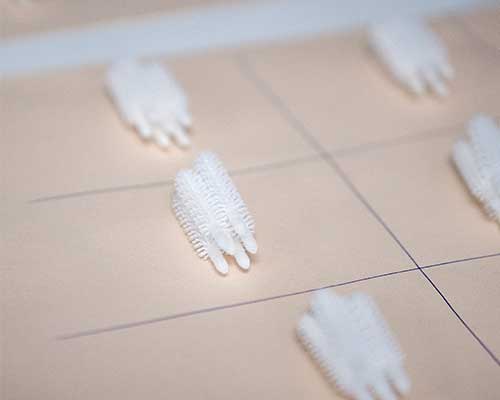

It allowed the fine tuning of the brush’s design through over 100 prototypes. Chanel says the unique shape of the brush would not have been possible with conventional manufacturing methods, such as plastic injection.

3D printing has also enabled the advancement of several features. The brush’s individual strands feature a granular texture, increasing their surface area and the ability of the mascara to adhere to eyelashes. Further, microcavities in the core of the brush hold a larger amount of mascara than previous brushes.

The rise of consumer-led 3D printing

Producers of consumer goods are increasingly turning to 3D printing for design and manufacturing. In the world of cosmetics Lush is experimenting with using 3D printing to create the designs and molds of some of their “blue sky” ideas as part of a £13 million innovation push.

In partnership with Carbon, Adidas are putting a bounce in the step of those lucky enough to have reserved a pair of their sold out AlphaEDGE running shoes, featuring 3D printed midsoles.

Seattle startup Prevolve are creating shoes with the perfect fit by 3D scanning their customer’s feet. And Bottletop introduced 3D printing to the design of its “sustainable luxury” fashion store in London.

For more of the latest consumer trends – subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Vote now in the 2018 3D Printing Industry Awards.

The 3D Printing Industry Jobs is live. Post a job or discover your next career move now.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your entries now with the chance of winning a 3D printer.

Featured image shows the inspection of a prototype of the Le Volume Révolution mascara brush. Image via Chanel Parfums Beauté.