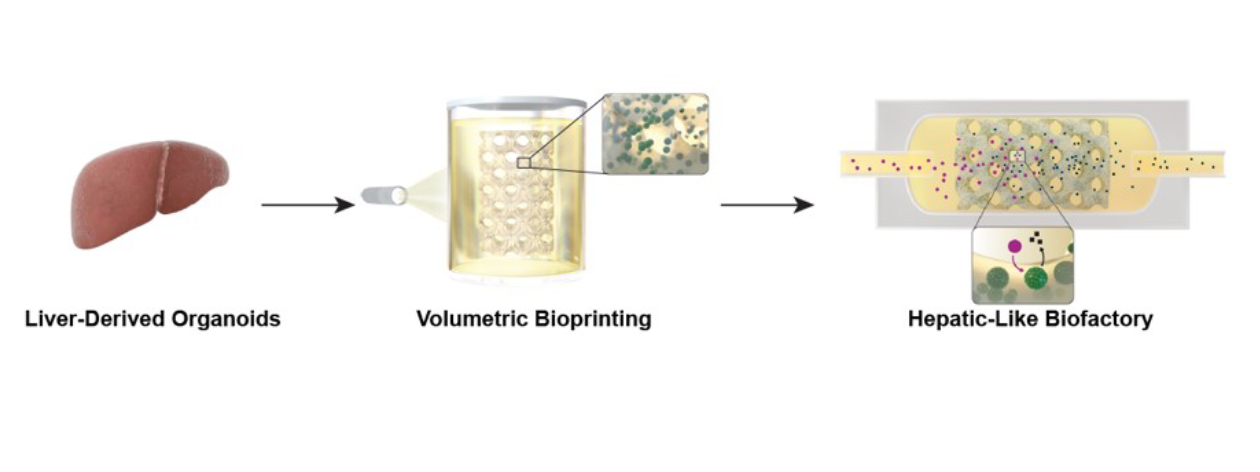

A research team from Utrecht University has successfully fabricated working livers using a newly developed ultrafast volumetric 3D bioprinting method.

By means of visible light tomography, the volumetric bioprinting method enabled the successful printing of miniature stem cell units by making the cells “transparent”, which meant they retained their resolution and ability to perform biological processes.

Printed in less than 20 seconds, the liver units were able to perform key toxin elimination processes mimicking those that natural livers perform in our bodies, and could open new opportunities for regenerative medicine and personalized drug testing.

Ultrafast volumetric 3D bioprinting

The Utrecht team first demonstrated their volumetric bioprinting technique in 2019 with the creation of free-form tissue structures. The method differs from current bioprinting processes which are based on layer-by-layer deposition and assembly of repetitive building blocks, such as cell-laden hydrogels and scaffolds.

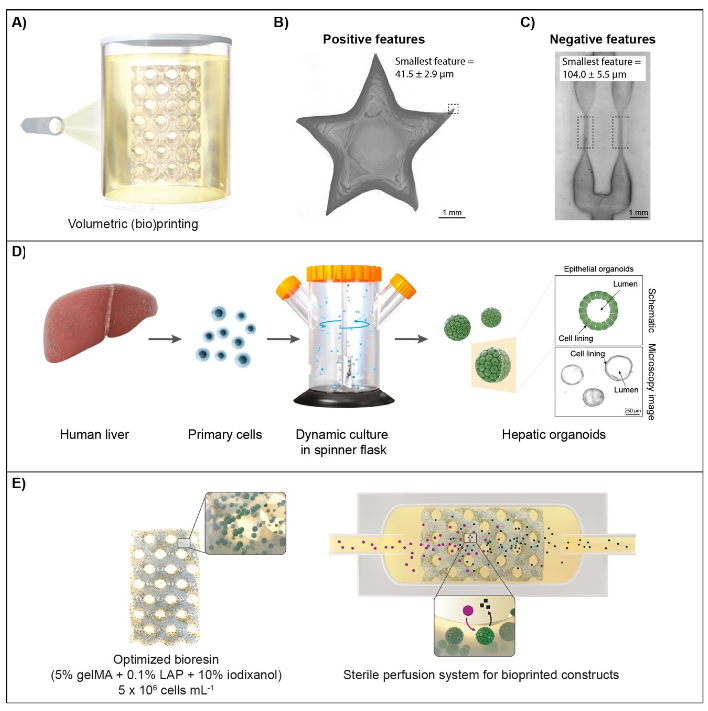

Instead, the volumetric bioprinting method involves projecting a series of 2D light patterns into a cylindrical container filled with cell-laden photoresponsive hydrogel, which triggers polymerization. One of the key benefits of the layerless, nozzle-free technique is that it poses no harmful mechanical stress on the cells, and is also capable of fabricating tissues at rapid speeds.

The work in 2019 prompted the spin-off of Readily3D, a manufacturer of volumetric 3D bioprinters, which announced its participation in the European ENLIGHT project last year. Readily3D is playing its part in the €3.6M project to 3D print a living model of the human pancreas in order to improve the testing of diabetes medication.

New volumetric bioprinting breakthrough

In their most recent work, the Utrecht team has achieved several key milestones in the development of their volumetric 3D bioprinting technique. The team focused on overcoming the main limitations of volumetric printing, such as loss of resolution due to light scattering caused by cells.

As volumetric printing relies on the precise patterning of light in 3D, it is typically only possible in highly transparent materials. Cells at high concentrations can scatter light which can significantly impede certain prints.

To combat this effect, the researchers developed a new material formulation using a bio-friendly compound commonly used in medicine as a contrast agent, iodixanol, which essentially makes the cells “transparent.” This allowed the team to achieve high printing fidelity even with high densities of cells, which is a crucial element for tissue engineering applications.

The team successfully fabricated functional liver units of more than 1 cm³ in less than 20 seconds by 3D printing organoids. Organoids are miniaturized units of around 1mm made from stem cells that copy aspects of their tissue of reference, in this case, the detoxifying capabilities of human livers.

On their own, organoids cannot be easily assembled into large structures needed to mimic human organs, and therefore their capacity for use in clinical settings is limited. The use of safe light and the contactless nature of the researchers’ volumetric bioprinting process, in addition to its rapid fabrication rate, ensured the safety of the organoids and kept them alive.

The Utrecht team was able to 3D print the organoids into different architectures to improve their ability to work as a liver, proving that bioprinting is a technology capable of improving the functional resemblance between printed structures and natural tissues. Through the study, they demonstrated that their printed architectures improved the organoids’ ability to detoxify and eliminate compounds harmful to the human body.

The researchers were also able to create different porous structures that could be perfused with nutrients in order to replace the role of blood vessels. According to Dr Riccardo Levato, Associate Professor at Utrecht University, the bioprinted liver units “open new opportunities for regenerative medicine and for developing new patient-specific models to study new drugs against liver diseases.”

Further information on the study can be found in the paper titled: “Volumetric bioprinting of organoids and optically tuned hydrogels to build liver-like metabolic biofactories,” published in the Advanced Materials journal. The paper was co-authored by P. Bernal, M. Bouwmeester, J. Madrid-Wolff, M. Falandt, A. Florczak, N. Rodriguez, Y. Li, G. Grossbacher, R. Samsom, M. Wolferen, L. van der Laan, P. Delrot, D. Loterie, J. Malda, C. Moser, B. Spee, and R. Levato.

Advances in 3D bioprinted organs

Although bioprinting has seen numerous advances in recent years, 3D printed viable, transplantable human organs still remain a long way off. Saying this, several firms are accelerating the technology’s development in the right direction.

For instance, industrial 3D printer manufacturer 3D Systems has ramped up its biofabrication activities over the past year after announcing “tremendous progress” in its Print to Perfusion platform. Soon after, the firm acquired biotech firm Volumetric Biotechnologies in a $400 million deal that will see the expansion of the company’s human lung scaffold research into two further organs, as well as investigating other vascular tissues.

Last month, Israeli regenerative medicine firm Matricelf signed an exclusive global licensing agreement with Tel Aviv University for its patent-pending 3D bioprinting technology. The technique involves bioprinting implants for the regeneration of damaged organs and tissues in the body, and has already been deployed to cure paralysis in mice.

Most recently, bioengineering start-up Trestle Biotherapeutics has gained a license for a new 3D bioprinting technology capable of producing functional human kidney tissues. Originally developed at Harvard University, the method will be used to create kidney cell transplants to help get people off dialysis and potentially full organs in the future.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows 12 volumetrically 3D printed liver architectures each measuring 1.7 cm in length and 6 mm in diameter with perfusable inlets, printed in 180 seconds. Image via Advanced Materials.