Readily3D, a manufacturer of volumetric 3D bioprinters, has announced its participation in the European ENLIGHT project.

Together with several research institutions and companies across the region, Readily3D will play its part in 3D printing a living model of the human pancreas in a bid to improve the testing of diabetes medication. Specifically, the company will be signing on as the project’s official bioprinter manufacturer, adapting its proprietary contactless tomographic illumination technology to suit the particular needs of pancreatic tissue structures.

The ENLIGHT project has been awarded a four-year grant totaling €3.6M by the Horizon 2020 Innovation Fund, and aims to fabricate its first set of working pancreas models within three years. The models themselves will be printed at UMC Utrecht and EPFL, which pioneered the use of volumetric printing for biofabrication applications back in 2019. ETH Zurich and the University of Naples will provide the specialized stem cells needed to complete the project.

Damien Loterie, CEO of Readily3D, states, “We are excited to be part of the ENLIGHT project and to push the frontiers of biofabrication together with our partners.”

Paving the way for high-speed bioprinting

To hit the three year target, the ENLIGHT researchers have two hurdles to jump. The first is the development of the bioprinter itself, which will be based on Readily3D’s existing Tomolite 3D printer. If all goes according to plan, the final product will be able to 3D bioprint living human cell structures at “lightning speeds”.

Where conventional 3D printers may take hours to fabricate centimeter-scale structures on a layer-by-layer basis, Readily3D’s volumetric printing technology will be able to achieve this in less than 30 seconds. The speed of the printer is reportedly especially important as the survival rate of living cells decreases drastically as print times increase.

Paul Delrot, CTO of Readily3D, explains, “With its rapid build speed, low light dose and sterile build environment, our tomographic bioprinter will open up previously inaccessible applications in biofabrication.”

Once the bioprinter is able to 3D print living pancreas models, the second hurdle will be to add signaling molecules to the structures, which will determine how the cells behave under external stimulation. This will essentially recreate the functionality of the cells at the human organ level, enabling the researchers to use the structures as a test pancreas for diabetes research without resorting to animal testing.

Professor Riccardo Levato, a biofabrication researcher at UMC Utrecht and coordinator of ENLIGHT, adds, “With cells from a patient, practitioners can recreate the diseased tissue. Subsequently, a laboratory test can be performed to determine which candidate medication has the greatest effect. This spares patients a long search with unpleasant side effects, saves on treatment costs, and leads to the best available care for individual patients.’’

Why focus on diabetes drug research?

According to the researchers, the choice to focus on diabetes and 3D print pancreatic tissue was a very deliberate one. Besides asthma, diabetes is the most common chronic disease in children, introducing a level of social relevance to the project. Furthermore, despite ongoing advances in medicine, the development of new diabetic treatments (apart from insulin therapy) is still an area that lags behind, calling for urgency in drug discovery.

Levato, referring to how the process can potentially be scaled up for other diseases such as cancers, adds, “The pancreas is our ‘proof of principle’. Once we manage to make a living model of the pancreas and actually test diabetes medication with it, this will prove the effectiveness of the new bioprinting technique. Then we can use those techniques much more widely. In principle, you can make living models of all types of tissue with it.”

With similar goals in mind, researchers at the University of Stuttgart and Robert Bosch Hospital recently announced the development of a novel 3D printed tissue platform that could replace animal testing in clinical trials. Backed by €3.8M from the German state of Baden-Württemberg, the scientists are attempting to fabricate an ex-vivo tissue model for testing cancer drug efficacy.

Elsewhere, scientists from Tsinghua University have previously 3D bioprinted brain-like tissue structures capable of nurturing neural cells from rats. After several weeks of in-vitro nurturing, the team was able to cultivate entire complex neural networks capable of responding to external stimuli, paving the way for novel drug research.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

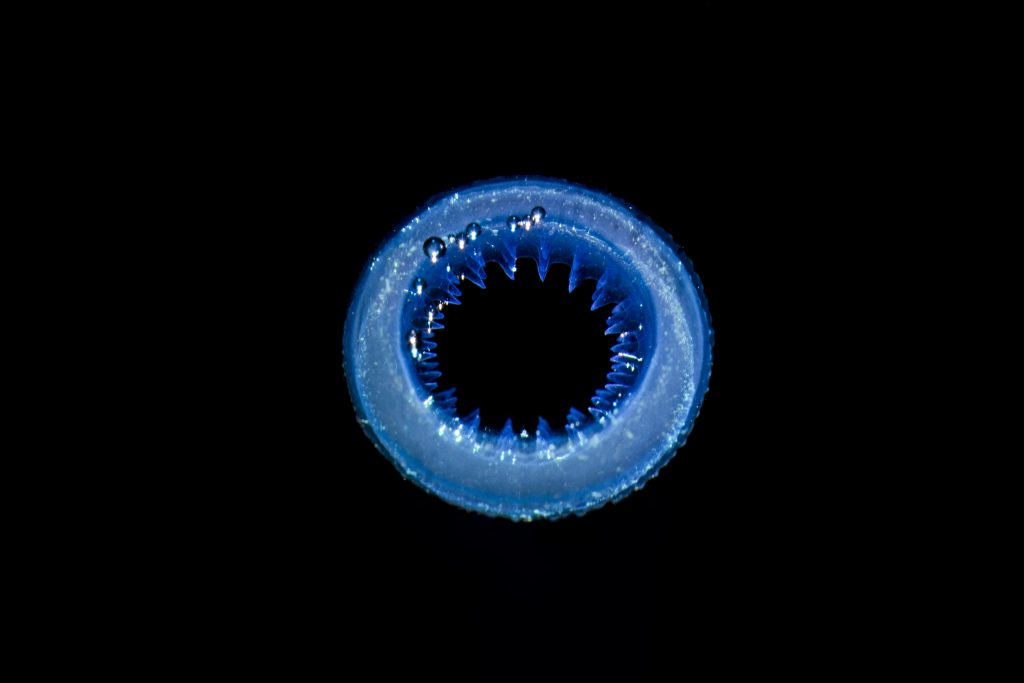

Featured image shows a human villus 3D bioprinted by Readily3D. Photo via Readily3D.