A European Union (EU) funded project is seeking to reduce animal testing within experimental medical research by means of 3D bioprinting.

Coordinated by the Institute of Bioengineering of Catalonia (IBEC), the BRIGHTER (Bioprinting by light-sheet lithography: engineering of complex tissues with high resolution and high speed) project is developing new 3D bioprinting processes for tissue engineering and regenerative medicine in order to reduce the use of animal models within these fields.

In particular, the project is focusing on fabricating human skin using a novel bioprinting technology based on patterned laser light sheets.

“Our innovative 3D bioprinting system not only achieves tissues that are closer to the real ones, but it is also much faster than current systems, a fundamental factor to ensure the viability of the new tissues,” said Professor Elena Martinez, Coordinator of the BRIGHTER project.

Reducing animal testing through AM

3D bioprinting has come on leaps and bounds over the past decade, with significant advances being made in the development of viable patient-specific tissues. While these developments hold promise for trialing the efficacy of drugs in the future, the tissues remain largely experimental and could still be decades away from human drug testing.

There is work being done within both academia and industry to change this, however, with the likes of Swedish bioprinter manufacturer CELLINK pledging to advance its research into animal cruelty-free cellular testing models, and the use of microscale skin models at the University of Stuttgart to trial the efficacy of cancer drugs in a bid to make animal testing obsolete.

Elsewhere, Fluicell’s Biopixlar platform has produced highly-complex neural models which could present future clinical drug screening applications, and UpNano’s NanoOne Bio system is focusing on the fabrication of cell-culturing microstructures which could help reduce the number of animal experiments behind clinical trials.

A BRIGHTER alternative to animal testing

Alongside IBEC, Goethe University Frankfurt, Israel’s Technion center, and biotechnology firms Mycronic and Cellendes are also taking part in the BRIGHTER project. The initiative hopes to overcome many of the technical obstacles currently limiting the fabrication of complex human tissues.

The partners are working together to develop a novel Light Sheet Bioprinting process capable of producing complex and accurate in vitro models that can be used for cosmetics and drug testing within the pharmaceutical industry and in research settings.

To fine-tune the technology, the BRIGHTER team is endeavoring to 3D print human skin, which is a highly complex tissue made up of multiple cell types and structures, such as sweat glands and hair follicles. Hydrogels will form a key component of the bioprinting process as they form the base from which cells will grow and form new tissue, and can also be personalized to individual patients using their own cells.

To print the skin with the desired structure, shape and consistency, the researchers are using advanced imaging techniques that combine illumination with light sheets and high-resolution digital photomasks. By applying a laser directly into the hydrogel, the cells within it can be “patterned” and molded to the right shape, enabling the team to control the 3D printed structure’s stiffness, shape, and dimensions.

The ability to mold the hydrogel with high levels of detail is particularly crucial to the successful printing of human skin, as the tissue is made up of numerous layers with different cell types. According to the BRIGHTER team, their bioprinting process is also capable of generating vascularization of the printed tissue and enabling the function of the sebaceous and sweat glands, and the hair follicles to grow hair.

“We hope to be able to print a skin sample with an area of 1cm² and a thickness of 1mm in approximately 10 minutes and with cell viability of more than 95 percent, greatly improving current bioprinting conditions,” said Dr. Nuria Torras, postdoctoral researcher at IBEC.

The BRIGHTER project hopes the successful printing of the in vitro skin models will validate their potential for use in both pharmaceutical and research environments, and ultimately reduce animal experimentation for drug and cosmetics testing.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

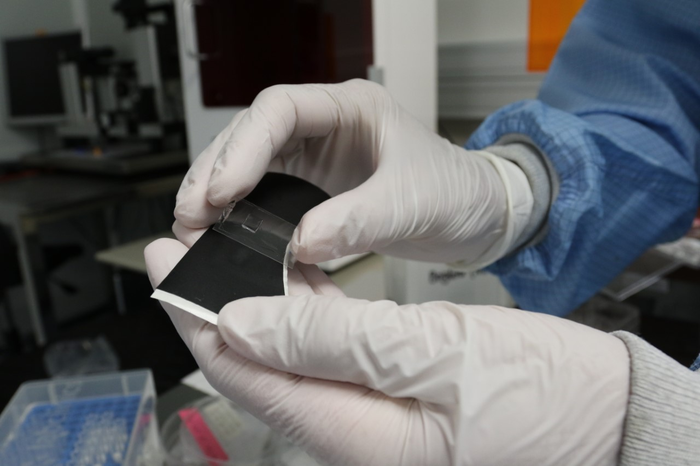

Featured image shows a small square of a matrix containing skin cells. Photo via IBEC.