UpNano, a manufacturer of two photon polymerization (2PP) 3D printers, has launched its new NanoOne Bio 3D bioprinting system.

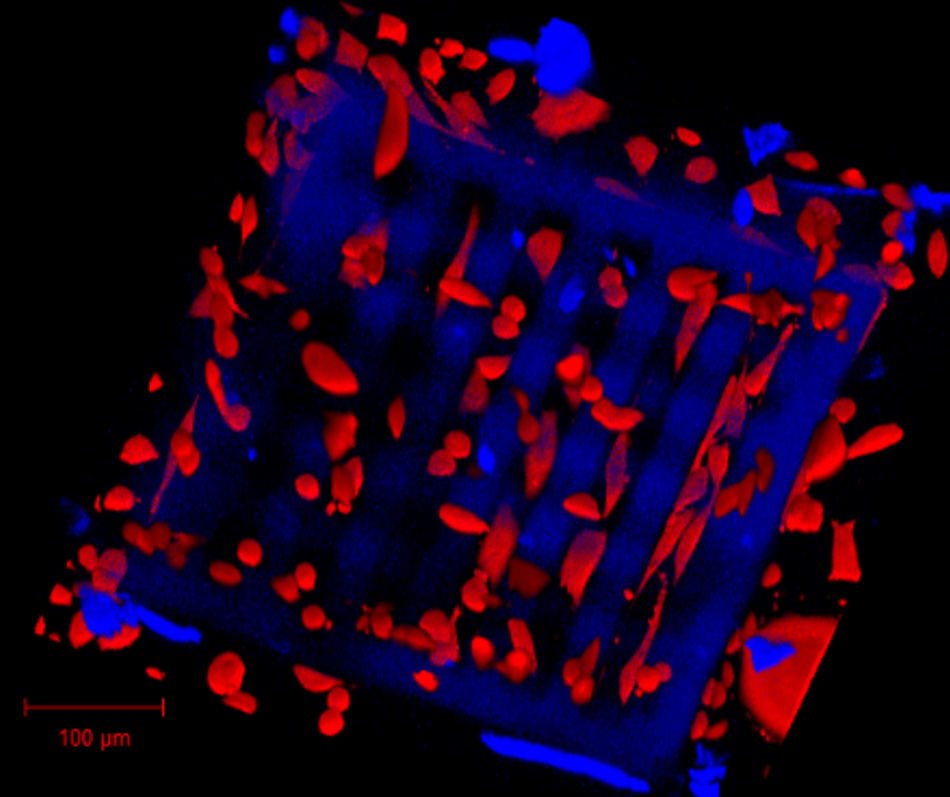

Based on the company’s flagship NanoOne 3D printer, the NanoOne Bio is capable of printing 3D tissue structures with living cells from the meso- to the nanoscales. The company has also partnered with biomaterial developer Xpect INX, a Ghent University spin-out, to create a hydrogel-based bioink for use with the new system. X Hydrobio INX U200 is reportedly the only commercially available resin that enables users to embed living cells directly into it from a culture plate.

“The combined competences of UpNano in developing 3D printing devices and Xpect INX in designing innovative materials for 3D bioprinting gelled well together,” said Peter Gruber, Head of Technology and Co-founder of UpNano. “We co-developed X Hydrobio INX U200, a highly biocompatible hydrogel, and at the same time we offer a 2-Photon 3D printing device that provides the largest range of printed dimensions on the market.”

The need for 3D cell cultures

Flat, 2D cell scaffolds have been the standard in biomedical research for a number of years now. However, according to UpNano, there is evidence to suggest that these 2D models do not accurately represent the 3D cellular interactions we find in living systems. As such, drug development based on 2D culture testing can often be misguided, resulting in millions in wasted R&D costs.

To date, the printing of highly-precise 3D scaffolds with embedded living cells has been held back by limitations in both materials and 3D bioprinting systems. The joint development of the NanoOne Bio and the X Hydrobio INX U200 resin looks to change this.

What does it mean for 3D bioprinting?

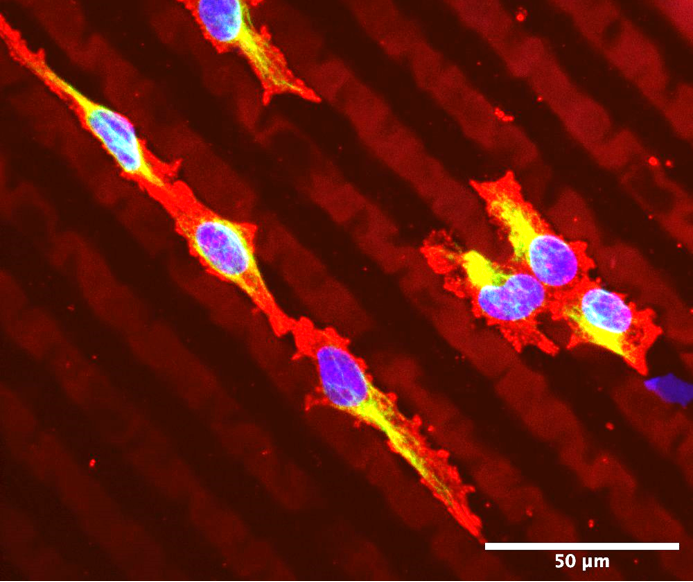

Xpect’s new bioink is a water-soluble hydrogel that enables users to integrate living 2D cell cultures directly from their petri dishes. Once embedded in the bioink, the cells can then be fed directly into the NanoOne Bio, where they are printed within complex 3D scaffolds. Since the system uses such a high-power laser, the printing of the structures is both precise and fast, meaning users will be able to fabricate centimeter-large constructs with ease.

“The gelatin-based X Hydrobio INX U200 has been specifically developed for the encapsulation of multiple cell types, thereby allowing the generation of complex 3D microtissues,” explains Jasper Van Hoorick, project lead at Xpect INX. “The hydrogel mimics the natural cellular environment and is biodegradable, thereby allowing the cells to gradually substitute the material with newly formed tissue.”

With the launch of the NanoOne Bio, UpNano expects customers in both academia and industry. Cell structures resembling real biological tissues can now be 3D printed, enabling natural interactions between cells and environmental stimuli. Pharmaceutical firms and research institutions alike will be granted the power to design cell models more closely aligned with real human body conditions, making drug development and other biomedical research safer and all the more reliable.

Due to the niche nature of bioprinting, many of the technological developments in the field still come directly from research institutions. Just last month, a team of researchers from the University of Bath and the University of Bristol developed a new 3D bioprinting technique that leverages acoustic energy. The sonolithography process uses computer-controlled ultrasound waves to precisely deposit biological particles and droplets into predetermined patterns on a substrate.

Elsewhere, at the King Abdullah University of Science and Technology, scientists recently developed a new method of 3D printing hydrogel scaffolds based on ultrashort peptides. These short chains of amino acids, the building blocks of proteins, were used to form the basis of a newly-developed, cell-infused 3D printing bioink.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the UpNano NanoOne Bio with its incubation chamber. Photo via UpNano.