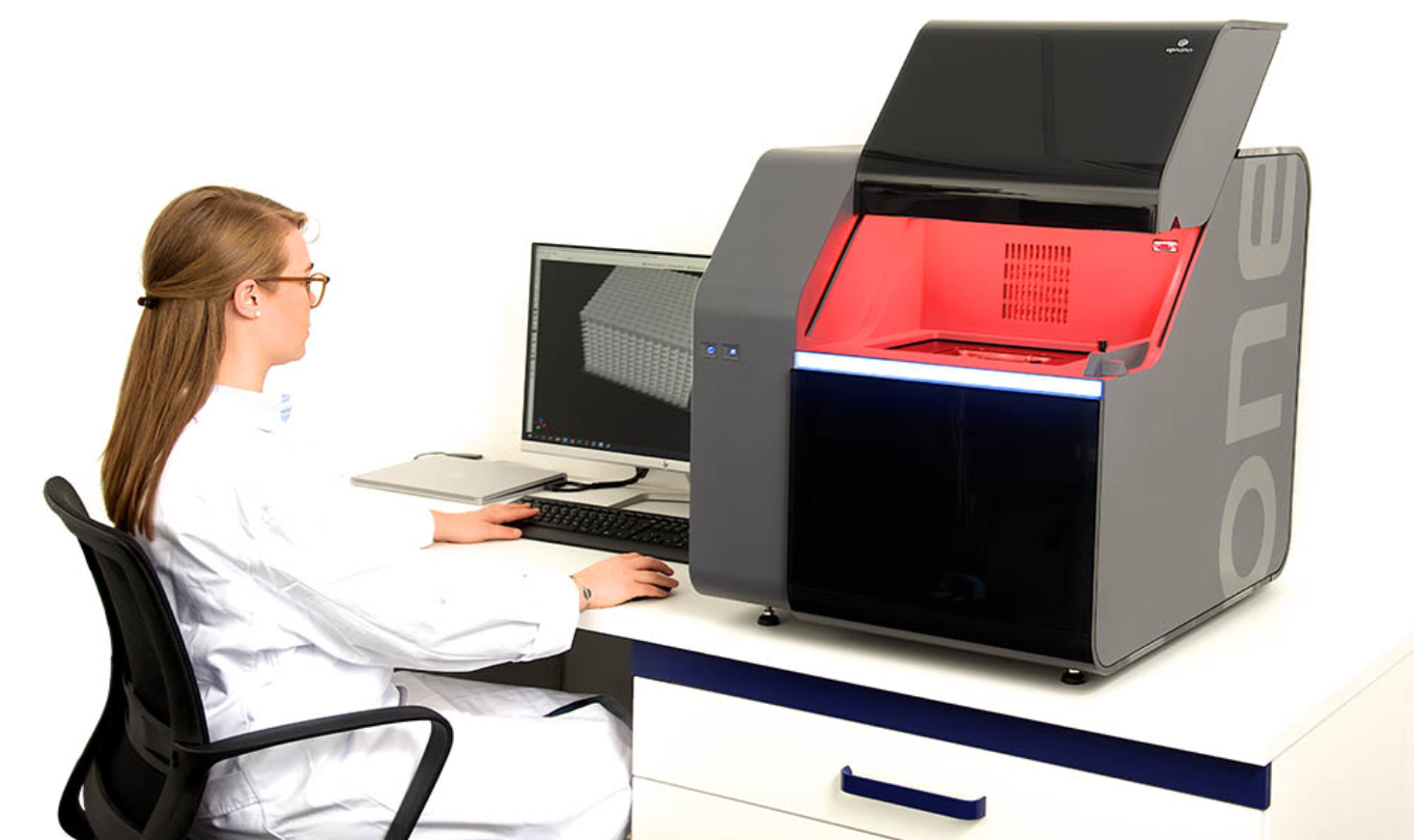

Vienna-based two photon polymerization (2PP) specialist UpNano has announced a successful market debut for its first commercial 3D printer – the NanoOne.

The TU Wien spin-out has already secured several customers across both industry and academia, recently doubling its headquarter floor space and appointing a new Head of Global Sales, Henrik Åkesson.

Åkesson states, “UpNano not only offers the best technology for speedy 2PP 3D printing over a wide range of dimensions, but it also benefits from a highly motivated and innovative team. And it is both that we offer our customers – state-of-the-art printing systems and services, that helps customers to really get the best out of these machines.”

2PP with UpNano

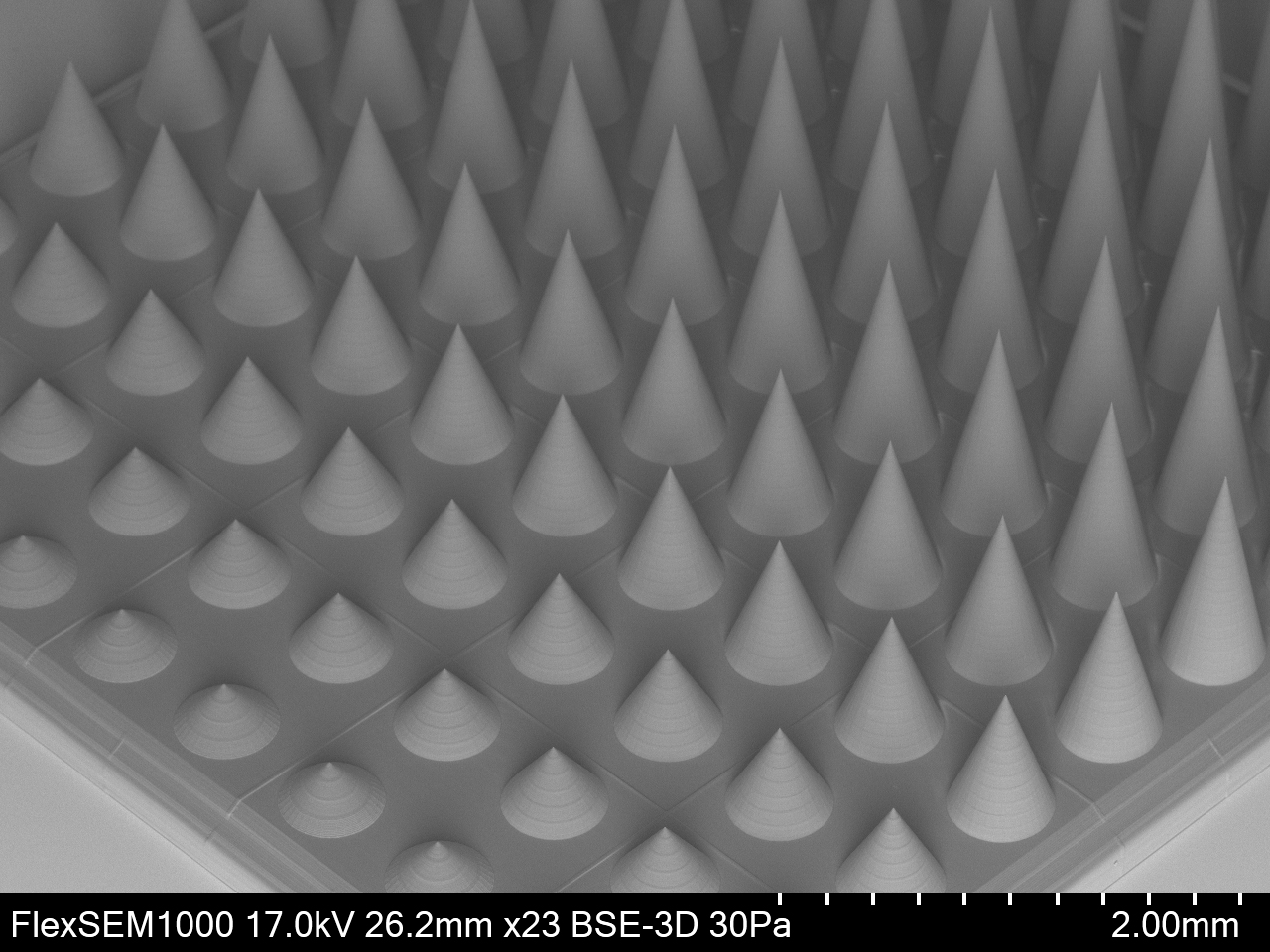

UpNano’s proprietary technology is characterized by its ultra-precision, enabling users to fabricate nanoscale parts with resolutions across 12 orders of magnitude. The resin-based production method also utilizes high-power lasers to speed up the printing process, meaning larger parts several centimeters in height are also possible to manufacture in a timely manner. This issue of print speed has historically been a limitation for similar systems in the market space, and is now one that UpNano is attempting to solve.

“We developed and patented an innovative adaptive resolution technology for our 3D printing system,” explains Peter Gruber, Head of Technology and Co-founder of UpNano. “Together with an optimized optical path and smart algorithms, we can utilize the full laser power up to one watt, which is several times more than in comparable systems.”

Serving both industry and academia

The NanoOne reportedly has a versatile design, so UpNano was able to tune each of its individual orders to the customers’ specifications. One such customer is an unnamed European company specializing in the production of optical systems.

The customer approached UpNano seeking a 2PP 3D printing system capable of fabricating highly transparent components. As well as providing the technology to accomplish this, UpNano leveraged its team of in-house experts to help develop a whole new material to suit the customer’s needs.

Bernhard Küenburg, CEO of UpNano, adds: “Our exceptionally strong laser allows us to add specific functionalities to the system that meet individual customer requests such as the ones of our industry partners.”

Over in the academic space, the University of Freiburg also purchased a NanoOne for its materials science department, with further investments by universities in the DACH region as well as in Scandinavia. As some of these universities were limited by funding, the company was able to provide a more basic version of the 3D printer, one that still meets all of the required technical specifications for advanced R&D, but at a lower cost.

It’s safe to say the nanoprinting market is considered fairly niche for the moment, but this isn’t to say competition isn’t fierce. Another major manufacturer, Nanoscribe, launched its Quantum X system back in 2019, with a specialism of fabricating micro-optics which can be as small as 200 microns. The company even recently launched its own specially formulated photoresin, which features a high refractive index and disperses easily.

Elsewhere, in Tel Aviv, OEM Nanofabrica has also previously commercialized its own two-photon industrial 3D printers. The technology is designed to produce parts with micron and sub-micron levels of resolution and surface finishes, and primarily targets the medical, automotive, aerospace, optics, and semiconductor sectors.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the UpNano NanoOne. Photo via UpNano.