Nanoscribe, a German manufacturer of two-photon additive manufacturing systems has introduced a new machine, the Quantum X. The latest system uses two-photon lithography for fabricating nano-sized refractive and diffractive micro-optics which can be as small as 200 microns.

Breaking the law

According to Dr. Michael Thiel, co-founder and CSO of Nanoscribe, “Beer’s law imposes strong limitations on today’s maskless lithography devices. Quantum X features two-photon grayscale lithography, which overcomes these limitations and offers unprecedented design freedom and ease-of-use. Our customers are working at the cutting edge of microfabrication.”

Nano 3D printing

Nanoscribe was founded as a spinoff of Karlsruhe Institute of Technology, and now has a subsidiary in Shanghai and an office in the U.S. The company is financially and technically supported by ZEISS, one of the oldest and largest manufacturers of optical systems in Germany.

Nanoscribe systems are based on two-photon absorption, a process in which a molecule is excited to a higher energy state. To fabricate 3D objects using the two-photon process, a gel containing monomers and two-photon active photoinitiators are used as raw material. A laser is fired onto the photosensitive material to form a nano-sized 3D printed object where the intensity of the absorbed light is the highest.

The Photonic Professional GT by Nanoscribe has found wide applications in research and is used at Harvard‘s Center for Nanoscale Systems, California Institute of Technology, Imperial College of London, ETH Zurich, and Keio University.

Recently, it was reported that Nanoscribe has also joined the MiLiQuant project, and will help bring quantum technology to an industrial level using its expertise in photon technology. In addition to two-photon machines, Nanoscribe also manufactures negative-tone resins, called IP Photoresins.

3D printing diffractive optics

Introduced at the on-going LASER World of Photonics 2019 (Booth A3.325) in Munich, the Quantum X system is specially designed for manufacturing diffractive optical elements (DOE). These micro-sized optic devices are used in the field of laser processing of materials, as DOEs can control the path and ‘shape’ of the laser with accuracy. Micro-optics are also used in LIDAR scanning and laser-based medical treatments.

One of the most common methods of manufacturing DOEs is based on the manufacturing process of integrated circuits, which can take up to twelve steps. However, with the Quantum X machine DOEs can go straight from CAD to print in a single step. According to Nanoscribe, Quantum X would be an ideal solution for rapid prototyping of micro-optics, small series production, and R&D.

Technical Specifications

| Printing technology | Two-Photon Grayscale Lithography (2GL) |

| Minimum XY size | 160 – 200 nm (depending on the photoresin used) |

| XY resolution | 400 – 500 nm (depending on the photoresin used) |

| Finest vertical steps | 10 nm |

| Scan speed | ≤ 250 mm/s |

| Area printing speed | 3 mm²/h typical for diffractive optical elements |

Learn more about microfabrication by subscribing to our 3D printing newsletter and joining us on Facebook and Twitter.

For jobs in the industry visit our 3D Printing Jobs page.

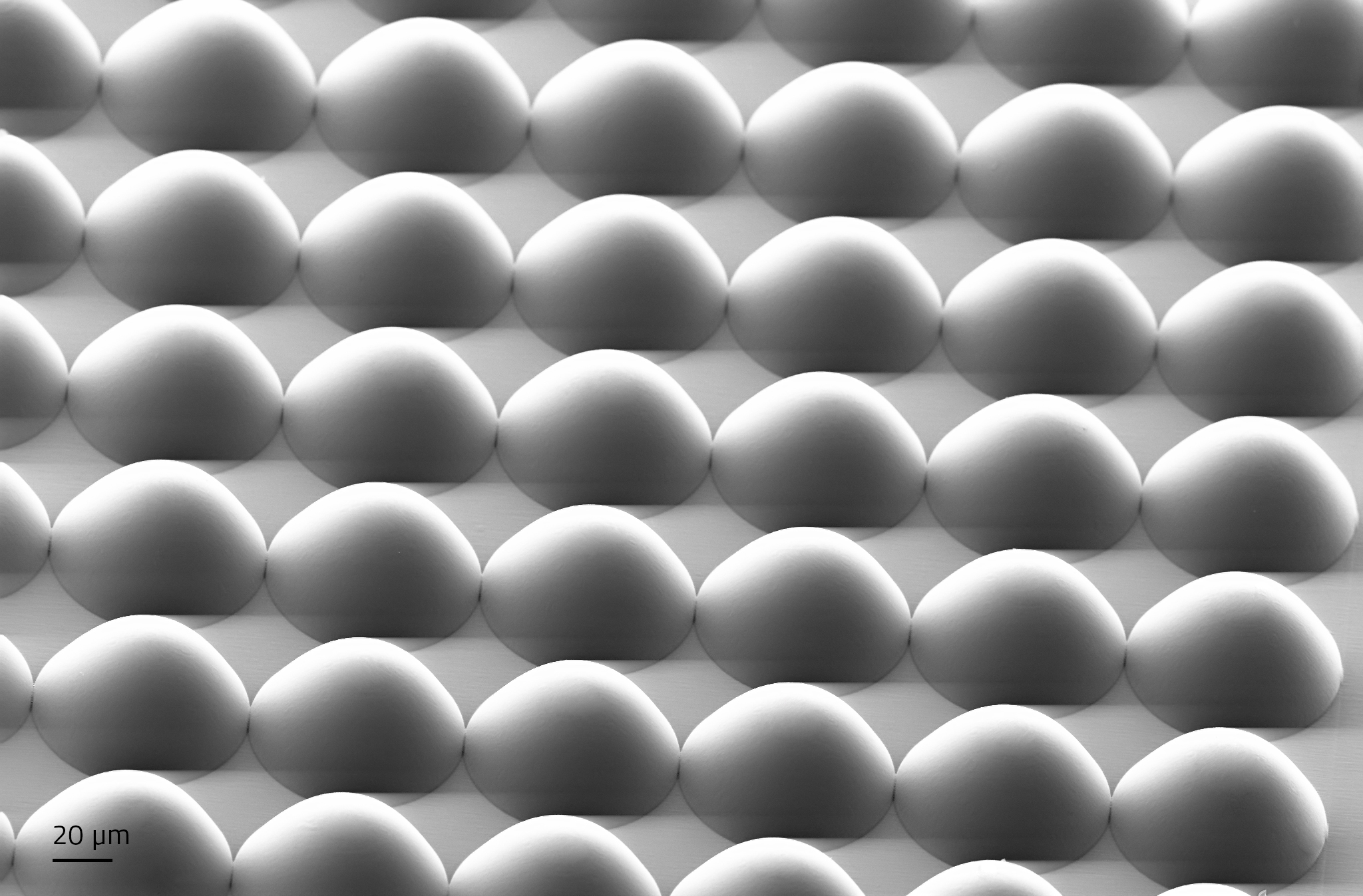

Featured image shows an SME image of microlens array 3D printed on a Quantum X machine. Image via Nanoscribe.