Nanofabrica, a Tel Aviv-based developer of precision additive manufacturing technologies, has launched its micron-level resolution industrial 3D printers, the Workshop System and the Industrial System.

Both platforms integrate the company’s patented process which is based on a Digital Light Processing (DLP) engine, and Adaptive Optics (AO), a technology used to improve image distortions in optical devices such as telescopes.

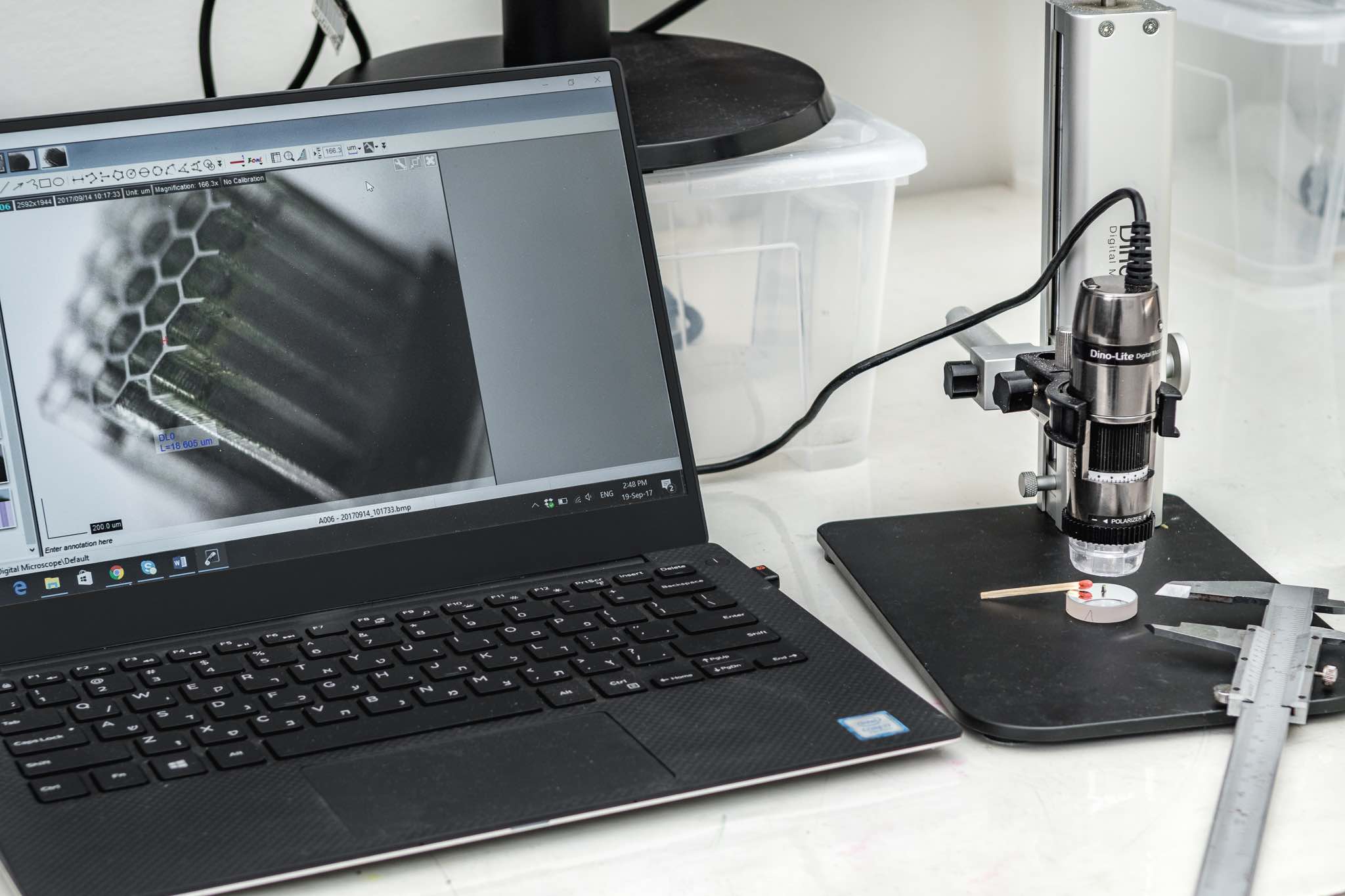

This technology is designed to produce parts with micron and sub-micron levels of resolution and surface finishes within the medical, automotive, aerospace, optics, and semiconductor sectors. Jon Donner, CEO of Nanofabrica, said:

“There is an inexorable shift towards miniaturization, with many applications demanding extremely exacting levels of micron and sub-micron precision on macro and micro parts [and] there is huge potential for an AM platform that can service this trend.”

“A whole raft of traditional production platforms have developed to cater for this demand, but until recently, the ability for AM to produce such precision at all —let alone at volume production levels — has been impossible.

3D printing the fine lines

With significant experience in material development, the engineers at Nanofabrica developed a range of proprietary materials, based on the commonly used industry polymers (ABS, and PP), which allow for ultra-high resolution. Such materials work in tandem with the company’s DLP process to produce micro-devices.

Ceramic-loaded materials with loadings of up to 80% have also been 3D printed by Nanofabrica, who is now developing 100% ceramic materials with 1-micron resolution.

The Workshop System and the Industrial System, which has a 5 X 5X 10cm build envelope, operate using this technology and material selection for digital mass manufacturing of precision parts. In medicine, this could entail microvalves, microsyringes, and micro implantable or surgical devices.

Micro and nano 3D printing

As a fairly new enterprise, Nanofabrica, founded in 2016, sought to be the first “mover” in the micro AM space for production. Now, with the commercialization of its technology, the company aims to help designers and manufacturers to further reap the benefits of additive manufacturing.

Simon Fried, President of fellow Israeli 3D printing company Nano Dimension, recognized Nanofabrica’s work with micro additive manufacturing. In a 2018 interview with 3D Printing Industry Fried said:

“At the other end of the size spectrum, researchers at MIT and start-ups like Nanofabrica are paying attention to printing very small parts. This can be expected to usher in new micro manufacturing capabilities.”

For more of the latest 3D printing news subscribe to the 3D Printing Industry Newsletter, follow us on Twitter and like us on Facebook.

Also, visit 3D Printing Jobs for new opportunities in your area.

Featured image shows a 3D printed micro-honeycomb structure in PP. Photo via Nanofabrica.