Scientists from medical tech company Fluicell have partnered with clinical R&D firm Cellectricon and the Swedish Karolinska Institutet university to 3D bioprint neural cells into complex patterns.

Using the microfluidic printheads featured on Fluicell’s Biopixlar platform, the researchers were able to accurately arrange rat brain cells within 3D structures, without damaging their viability. The resulting cerebral tissues could be used to model the progress of neurological diseases, or to test the efficacy of related drugs.

“We’ve been using Biopixlar to develop protocols for the printing of different neuronal cells types, and we are very pleased with its performance,” said Mattias Karlsson, CEO of Cellectricon. “This exciting technology has the potential to open completely new avenues for in-vitro modeling of a wide range of central and PNS-related diseases.”

Fluicell’s precision printing process

Having spun-off from the Chalmers University of Technology in 2012, Fluicell opted to launch its first bioprinter in November 2019 with the Biopixlar. The machine is marketed as an “all-in-one discovery platform,” that’s capable of printing multiple different cells in one run, while maintaining a high level of precision and resolution.

Fluicell’s system includes a mechanical arm, motorized stage and a gamepad interface, that allows users to manually position and deposit cells. The level of precision provided by the machine lends it potential tissue printing applications, and since its launch, the company has sought to exhibit its clinical capabilities.

In one such demonstration, the firm signed a beta deal with Cellectricon, through which it aims to evaluate the use of its technology within neural research. Given that mapping brain diseases often requires the use of various cell types, the partners theorized that the Biopixlar could be used to improve patient prognosis.

Previous approaches to printing artificial tissues have focused on extrusion or laser-based methods, many of which require the use of a sacrificial gel that limits their accuracy. Contrastingly, using a microfluidic process, the Fluicell team found that they were able to precisely control deposited cells, without inhibiting their growth.

Beta-testing the Biopixlar printer

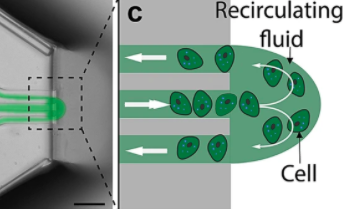

A key advantage of the Biopixlar, is that it features a printhead with three separate chambers, and during testing, the team were able to avoid cross-contamination. The cells were also confined to a recirculatory flow, meaning that they weren’t deposited until they interacted strongly enough with a surface to attach.

Using this approach, the scientists were able to collect and reuse any unattached cells, while maintaining a high level of control over cell patterning. What’s more, through careful pressure balancing, the team found that they could adjust the ratio and layout of the tissues in real-time, making the process extremely adaptable.

In more advanced tests, the researchers printed both adult skin and cancer cells into 2D tissues, which exhibited a survival rate of more than 99%. Once exposed to the Retinoic Acid (RA) skin drug, the cancer cells’ tumor-generating CK 10 proteins declined by 25%, demonstrating the tissues’ potential within clinical research.

By attaching several of these 2D tissues using polylysine (PLL) as a cellular ‘glue,’ the team were ultimately able to layer them into a living brain cancer model. According to the scientists, their novel PLL-based approach showed that the Biopixlar was sufficiently non-invasive and precise to warrant its wider use as a diagnostic tool.

Bioprinting soft tissue structures

Although fully-sized 3D printed human organs remain years away from reality, scientists have managed to make significant progress in fabricating smaller tissues for specific purposes.

Researchers at Tsinghua University, for instance, have also 3D bioprinted brain-like tissues that are capable of nurturing neural cells. After injecting their additive structures into the cortex of a lab rat, the team found that they were able to form a stimuli-responsive circuit.

3D bioprinting firm T&R Biofab, on the other hand, has partnered with pharmaceutical company HK inno.N to fabricate a series of artificial skin ‘test subjects.’ The cellular structures are part of an in-depth research program into the effectiveness of different skin disease medications.

Elsewhere, a collaborative group of U.S. universities have taken a different approach, and developed a method of 3D bioprinting tissues directly inside the body. The team’s process is based on a novel bio-ink that’s capable of constructing cells in-vitro, thus removing the risk of any potential surgical complications.

The researchers’ findings are detailed in their study titled “3D micro-organisation printing of mammalian cells to generate biological tissues.” The paper was co-authored by Gavin D. M. Jeffries, Shijun Xu, Tatsiana Lobovkina, Vladimir Kirejev, Florian Tusseau, Christoffer Gyllensten, Avadhesh Kumar Singh, Paul Karila, Lydia Moll and Owe Orwar.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

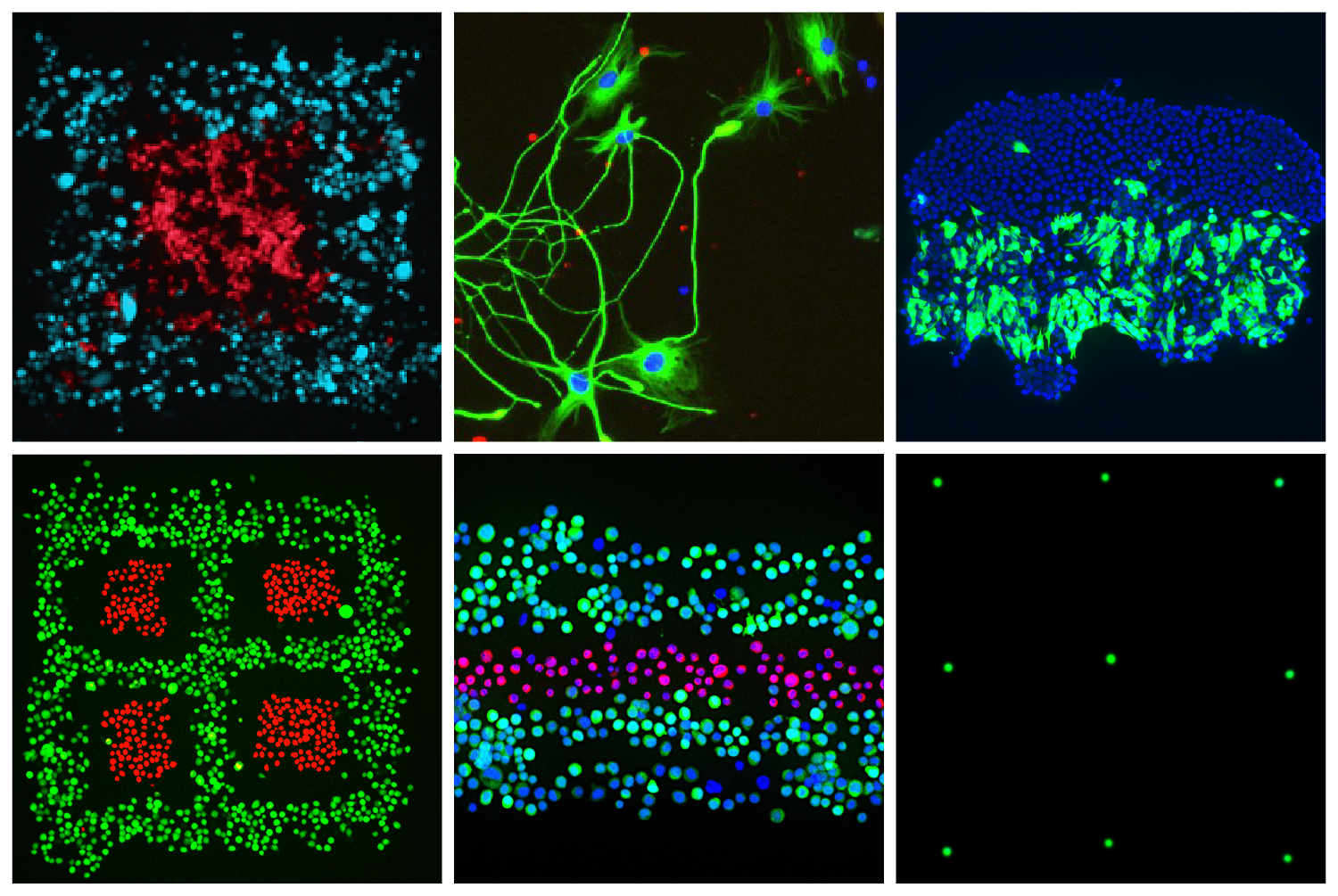

Featured image shows a selection of the 3D printed cell-based structures that the team produced during their research. Image via Fluicell.