A group of researchers from the Terasaki Institute for Biomedical Innovation, Ohio State University and Pennsylvania State University have developed a specially-formulated bio-ink designed for 3D bioprinting tissue directly in the body.

The team embarked upon the project in order to overcome the drawbacks of in vitro tissue engineering procedures, which poses increased risks to patients, with potential for further complications post-implantation.

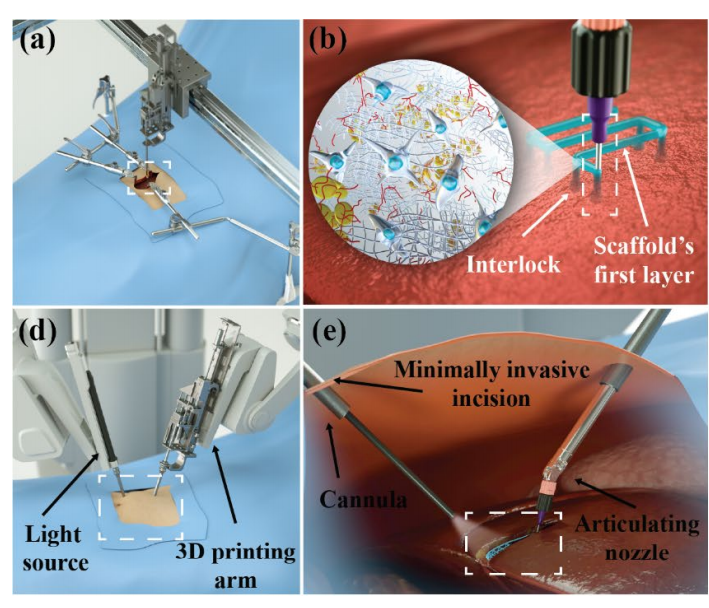

Further invoking Westworld-like imagery, the researchers propose that the bio-ink formula to build the tissue can be applied via direct robotic 3D printing technology within the body itself. Potential applications for the bioink and 3D printing technique, explain the team, lies in biofunctional hernia repair meshes, improving ovary functions, the 3D printing of complex cell-laden scaffolds for restoring tissue/organ function, and the delivery of drug-loaded or growth factor tethered biomaterials.

“Developing personalized tissues that can address various injuries and ailments is very important for the future of medicine,” comments Ali Khademhosseini, an author on the study.

“The work presented here addresses an important challenge in making these tissues, as it enables us to deliver the right cells and materials directly to the defect in the operating room.”

Methods of tissue engineering in 3D printing

The researchers begin by explaining the current paradigm for tissue engineering, which centers on manufacturing biomaterial scaffolds outside the body, which is then implanted via an open surgery.

With 3D printing playing an increasing role in medicine and surgical procedures, this in vitro condition has also applied to the different ways in which 3D printing is used in the medical sector. For example, 3D printing has been used to produce parts of the body such as orthopedic joints and prosthetics, which are attached to the body after they are fabricated. Numerous examples highlight the advantages 3D printing brings to orthopedic procedures; last year, Robert Smith, an iron worker from St. Petersburg, Florida, became the first person to receive a 3D printed finger bone implant in the U.S., where operation would have been too complicated.

According to the Terasaki Institute, 3D printing can also be used to produce and restore portions of bone, skin and blood vessels, which are often created in an apparatus outside of the body and surgically implanted.

However, the in vitro method of surgical implantation often involves making large surgical incisions, posing the added risk of infection and increased recovery time for the patient. Furthermore, there is a time lapse between when the tissue is created and when it is implanted in the patient, which can cause further complications to occur. To prevent these complications, the group of researchers sought to develop a technology for 3D printing tissues directly in the body.

3D printing the tissue in vivo

In order to produce engineered tissue, two basic components are required: a bioink consisting of a framework material mixed with living cells, and growth factors to help the cells grow and develop into regenerated tissue.

Developing tissues for direct implantation into the body necessitates further considerations, including the construction of tissue at body temperature (37°C), and identifying a method for effectively attaching the tissue to soft, live organ tissue. Furthermore, any procedural steps should not be harmful to the patient, however one such harmful step in current methods is the application of harmful UV light necessary to solidify the constructed tissue. Ali Asghari, first author on the study, explains that “This bio-ink formulation is 3D printable at physiological temperature, and can be crosslinked safely using visible light inside the body.”

Instead, in order to build the tissue, the researchers identified the use of robotic 3D printing, which utilizes robotic machinery affixed with a nozzle. The bio-ink can then be dispensed through the nozzle, in a highly-precise, programmable manner.

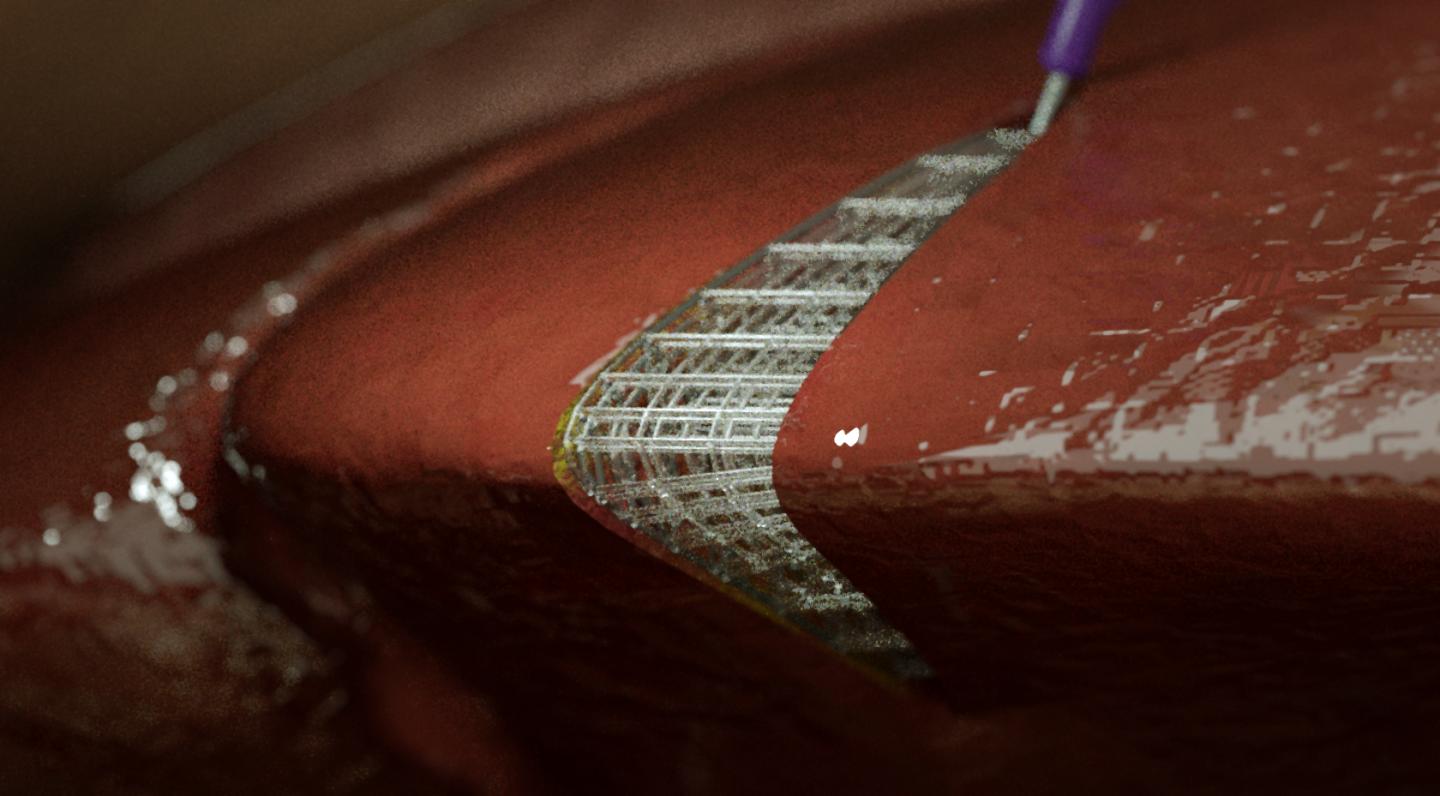

Testing the 3D printing technology and bioink, the researchers worked on methods to attach pieces of the tissue formed with this bio-ink onto soft surfaces. These experiments included attaching tissue structures onto pieces of raw chicken strips using the robotic 3D printer and the specially-formulated bio-ink, while also developing a novel interlocking mechanism.

The research team modified the nozzle tip so that it was able to penetrate the raw chicken’s soft surface and fill the punctured space with bio-ink as it withdrew. This helped to establish an anchor for the tissue construct. As the nozzle tip reached the surface, it dispensed an additional blob of bio-ink to “lock in” the anchor. “The interlocking mechanism enables stronger attachments of the scaffolds to the soft tissue substrate inside the patient body,” comments Asghari Adib.

The paper concludes that a biomaterial that can be 3D printed at physiologically relevant and safe conditions is a necessary component for intracorporeal tissue engineering via direct-write 3D printing. “In this study, by introducing rheological modifiers to GelMA, we developed a formulation that was 3D printable into complex shapes at 37 °C and could be crosslinked in situ using a safe, visible light crosslinking system.”

Such advances in tissue engineering are instrumental in providing lower-risk, minimally-invasive laparoscopic options for tissue repair procedures. This would improve safety for the patient, as well as saving time and being more cost-effective. Further modifications in tissue engineering design and the adjustment of other conditions may increase the potential for customization.

The paper, “Direct-write 3D printing and characterization of a GelMA-based biomaterial for intracorporeal tissue engineering,” is written by Ali Khademhosseini, Ph.D., David J Hoelzle, Ph.D., Amir Sheikhi, Ph.D., Melika Shahhosseini, Andrej Simeunovic, Ph.D., Shuai Wu, Carlos Castro, Ph.D., and Ruike Zhao, Ph.D. It is published in Biofabrication.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.