A team of scientists have developed a new FDM 3D printer that can automatically create parameters for unknown materials.

Material presets for mass-manufactured polymers can be found on most 3D printers. However, the 3D printing parameters for sustainable and recycled materials need to be manually adjusted. This trial and error process can be frustrating and time-consuming, limiting the adoption of environmentally friendly filaments.

Experts from MIT’s Center for Bits and Atoms (CBA), the U.S. National Institute of Standards and Technology (NIST), and Greece’s National Center for Scientific Research (Demokritos) are working to change this.

The team built an extruder that can measure key filament information during the 3D printing process. This data was inputted into a mathematical model, which automatically generated the material’s optimal 3D printing parameters.

According to the team’s research paper, this new methodology could increase the adoption of unique FDM filaments that are more sustainable than hard-to-recycle fossil fuel-based polymers.

“In this paper, we demonstrate a method that can take all these interesting materials that are bio-based and made from various sustainable sources and show that the printer can figure out by itself how to print those materials,” explained senior author Neil Gershenfeld in an interview with MIT News. “The goal is to make 3D printing more sustainable.”

Automatically generating material parameters

3D printing with renewable and recycled materials can be a challenging process. Due to variations in their properties, no two materials are alike. For instance, bio-based polymers can feature different plant mixtures based on the season. This poses problems when it comes to determining what 3D printing parameters to use.

The researcher’s new approach overcomes these challenges by automatically identifying the optimal parameters for previously unknown materials.

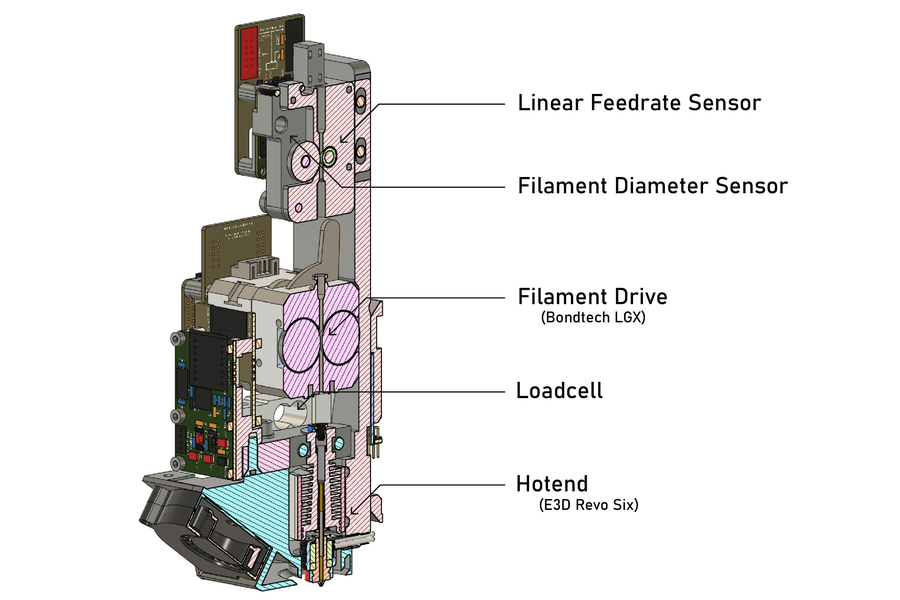

To achieve this, the team adopted a 3D printer from the MIT lab and added three sensors to its extruder. A load cell was used to measure the pressure applied to the filament. Feed rate sensors tracked filament thickness and the rate at which material was pushed into the 3D printer’s hotend.

A 20-minute test, designed to record several temperature and pressure readings at different flow rates, was conducted for each material.

During this test, the team set the 3D printer’s nozzle to 290℃, its highest possible temperature. The material was extruded at a fixed rate. Then, the heater was turned off while the filament continued to be pushed into the hotend.

The data was fed into a mathematical function that automatically produced the ideal parameters. Once these are imputed into slicing software, the material can be 3D printed with optimal results.

The team experimented with six different materials, many of which were bio-based. Their method automatically generated parameters that enabled complex objects to be successfully fabricated.

Alysia Garmulewicz, an associate professor in the Faculty of Administration and Economics at the University of Santiago, told MIT News that this new methodology “opens the door to the use of recycled and bio-based filaments that have variable and unknown behaviors.”

Looking ahead, the MIT-led team plans to directly connect its process to 3D printing software, removing the need to input the parameters manually.

Researchers target sustainable 3D printing

The global 3D printing industry is witnessing an increasing focus on sustainability, including through the use of more environmentally friendly materials. This is especially important when it comes to FDM 3D printers. UK-based filament manufacturer Filamentive recently reported that this 3D printing process produces 400,000 kg of plastic waste each year in the UK alone.

Scientists are attempting to combat this with research into recycled 3D printing filaments. A team from the United Arab Emirates University developed a PLA filament made from recycled plastic and carbon fiber waste. The discarded material was shredded, ground, mixed, and melt-blended. These formulations were then hot-pressed into dogbone specimens, with a universal testing machine used to characterize the composite’s mechanical performance.

Having demonstrated that it is possible to recycle PLA and carbon fiber simultaneously, the researchers hope that others will investigate more efficient methods of creating recycled composites.

Bio-based filaments also offer the potential for greener FDM 3D printing. Previously, scientists at the Michigan Technology University created 3D printable wood filament from furniture waste. Co-authored by open-source advocate Joshua Pearce, the research paper outlines a method for combining this waste material with PLA to create a wood-plastic composite (WPC).

With 150 tons of furniture wood waste produced daily in Michigan, the researchers acquired discarded MDF, LDF, melamine, and sawdust. This material was reduced to powder and mixed with PLA pellets to create the recycled filament. Once ready, the team successfully leveraged the material to 3D print a wooden cube, a doorknob, and a drawer handle.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

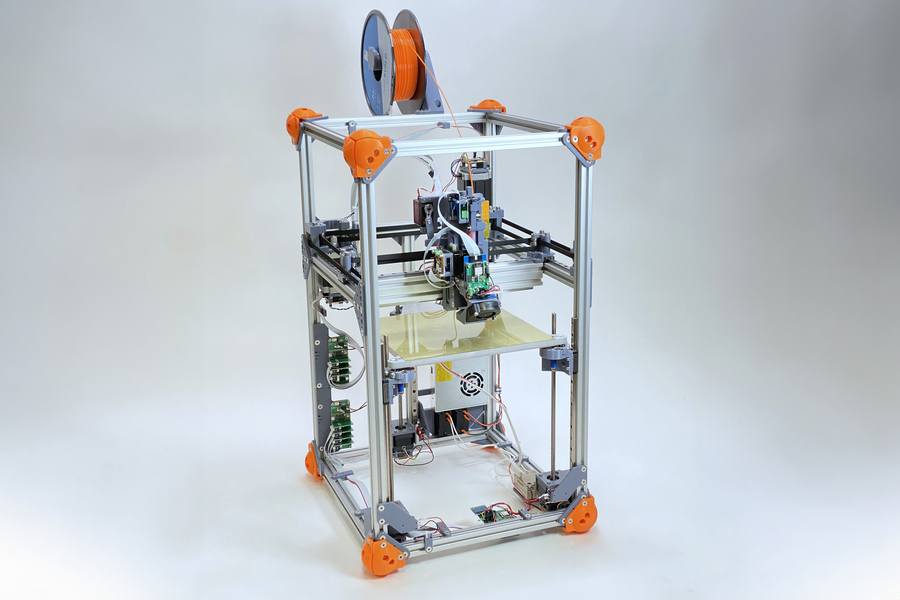

Featured image shows the researchers’ 3D printer. This can generate parameters for unknown materials. Photo via MIT News.