Researchers from the United Arab Emirates University are exploring the development of recycled composite materials using leftover 3D printed PLA and carbon fiber waste.

Plastic consumption has been on the rise since its invention over a century ago, resulting in polluting waste that poses a challenge for both humanity and the rest of Earth’s ecosystem. In recent years especially, there’s been a push towards ‘green initiatives’ that work to realize a more sustainable society. One such initiative is recycling, whereby polymers like 3D printed PLA waste are repurposed for new applications.

Similarly, composite materials have also seen increased demand over the years, with carbon fiber reinforcements having applications in both conventional manufacturing and 3D printing. Much like polymers, the widespread use of carbon fibers in industries such as automotive and aerospace is fueling an ever-worsening waste issue.

Taking the opportunity to strike two birds with one stone, the UAE researchers have found a way to repurpose two different waste streams and address the material needs of the composites sector.

Carbon fiber-reinforced PLA

Polylactic acid, or PLA, is a bio-based polymer that’s created using lactic acid from the sugar fermentation process. It was initially intended as a more environmentally-friendly alternative to crude oil-based polymers and is technically biodegradable (albeit in industrial composting conditions). As well as being the most widely-used polymer in the desktop 3D printing space, PLA also has a variety of applications in packaging, disposable cups, and more.

Although it’s very cost-effective, easy to process, and easy to 3D print, PLA in its pure form offers poor thermal and mechanical stability so it’s not suitable for any high-performance applications.

One way of improving the material’s characteristics is with additives such as carbon fiber reinforcements, as carbon fiber composites can offer an excellent blend of mechanical properties and heat resistance.

How did the recycled composites perform?

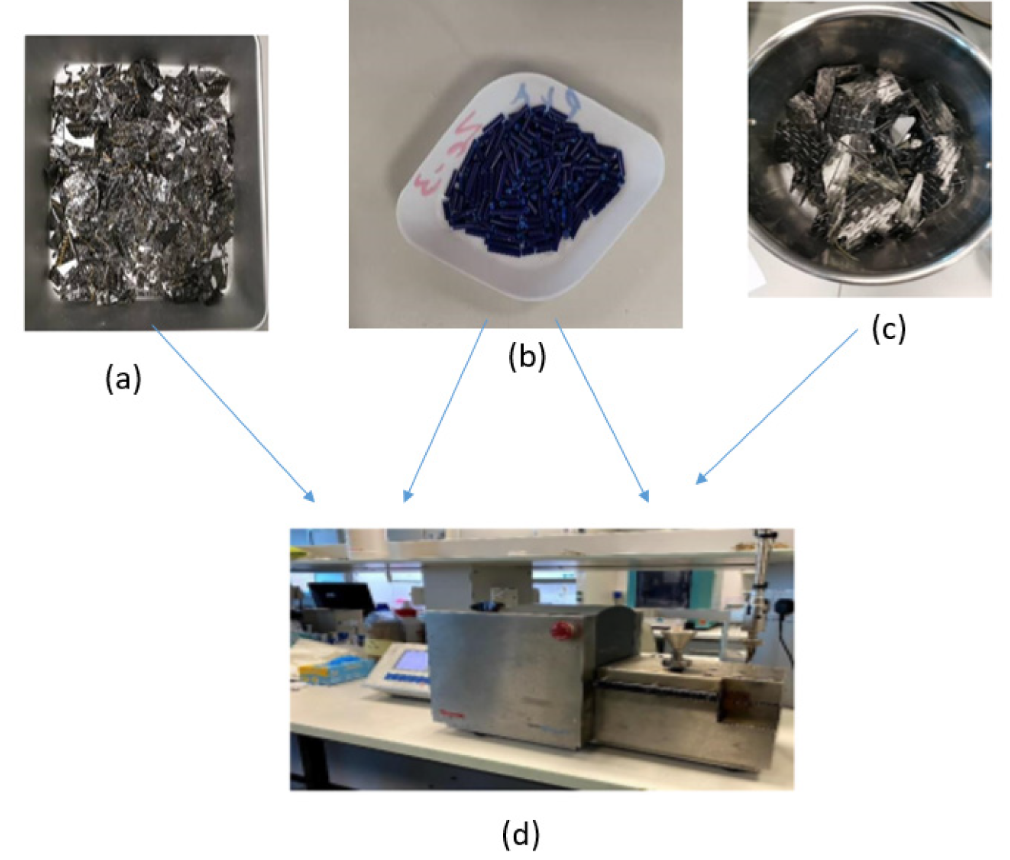

To create their recycled composite materials, the UAE team collected leftover 3D printed PLA from the prototyping labs at the university. To obtain the carbon fiber element of the composites, waste material from CF-prepreg sheets and carbon fiber sheets was used. The PLA and carbon fiber waste were shredded, ground, mixed, and melt-blended in varying percentages of additives.

The team then hot-pressed the formulations into dogbone specimens and used a universal testing machine to characterize the mechanical performance of the recycled composites.

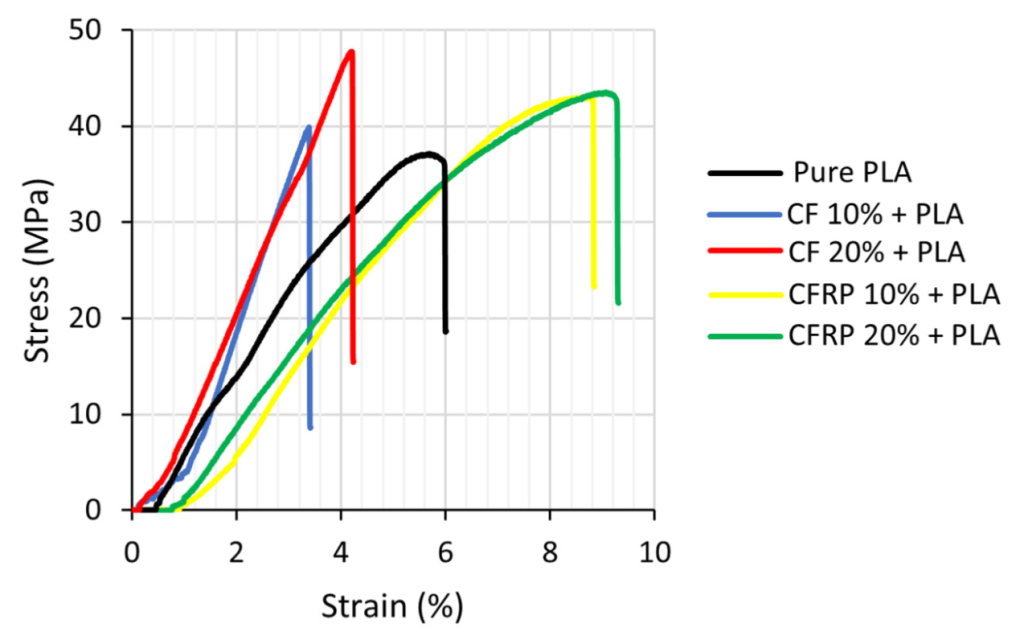

Interestingly, the researchers found that both the additive percentage and the type of filler had an impact on mechanical performance. For example, the 20% carbon fiber composite had a higher modulus of elasticity than the 20% carbon fiber-prepreg sheet composite.

All in all, the carbon fiber reinforcements generally improved the strength of the PLA, with the 20% carbon fiber composite offering the highest yield strength. However, higher reinforcement percentages were also found to have greater negative effects on the ductility of the material.

The work has demonstrated that it’s possible to recycle both PLA and carbon fiber at the same time to develop green composites with tunable properties. The authors hope their project can act as a stepping stone for others to investigate more efficient methods of creating recycled composites for industry.

Further details of the study can be found in the paper titled ‘Carbon Fiber/PLA Recycled Composite’.

There’s an active market for environmentally-conscious materials in 3D printing. Just this month, Brazilian petrochemical firm Braskem released its first line of sustainable 3D printing filaments. The launch includes FL600EVA-BIO, a bio-based EVA filament derived from raw sugar cane, as well as recycled polyethylene (PE) and polypropylene (PP) offerings.

Elsewhere, at the University of Bath, researchers recently developed a new way to make PLA material break down using just UV light. By adding some sugar into its composition, scientists at the university’s Centre for Sustainable and Circular Technologies (CSCT) have shown that PLA can indeed degrade in natural conditions in a matter of hours.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a carbon fiber composite sheet. Image via Furo Systems.