Scientists at the US Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL) have produced a neutron collimator using binder jet 3D printing.

Neutrons are often used to study energy and matter at the atomic scale through a method called neutron scattering. During this process, neutron collimators guide neutrons toward a detector and prevent stray neutrons from interfering with data collection.

Collaborating with ORNL’s Manufacturing Demonstration Facility (MDF), the researchers initially sought to scale up an existing collimator design. However, the single-piece 3D printed device was found to be imprecise and cracked during the manufacturing process.

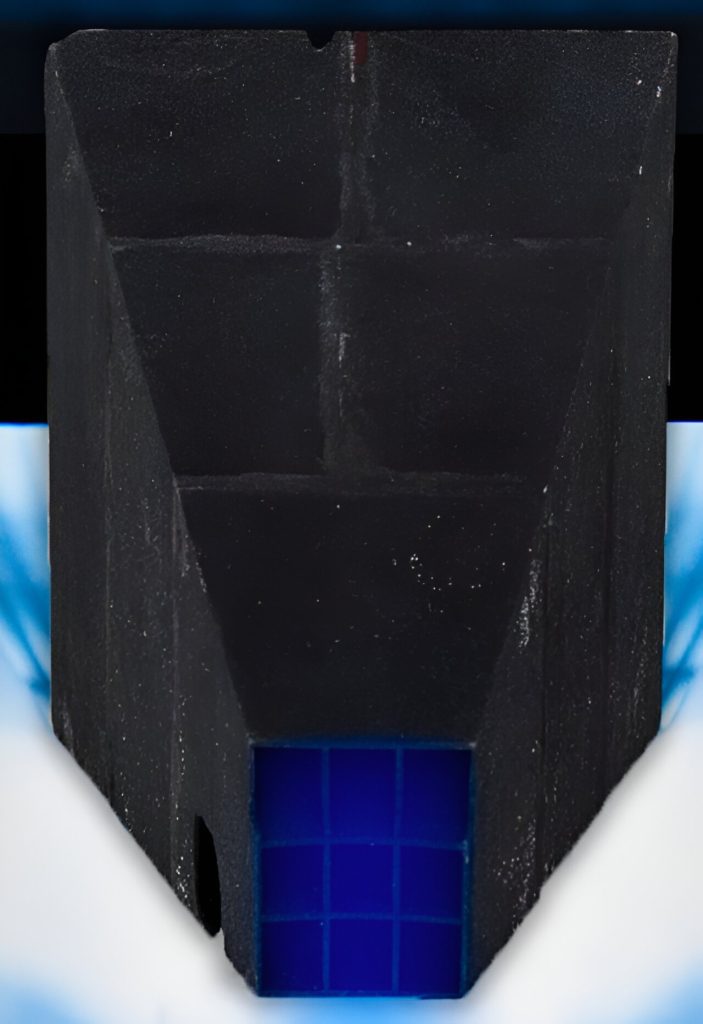

To overcome these challenges, the team fabricated multiple smaller parts, which were then manually assembled into the complete collimator. 3D printed with Boron Carbide (B4C), an extremely hard material often found in military hardware, the reduced size of these parts allowed them to cool more uniformly and facilitated greater design flexibility.

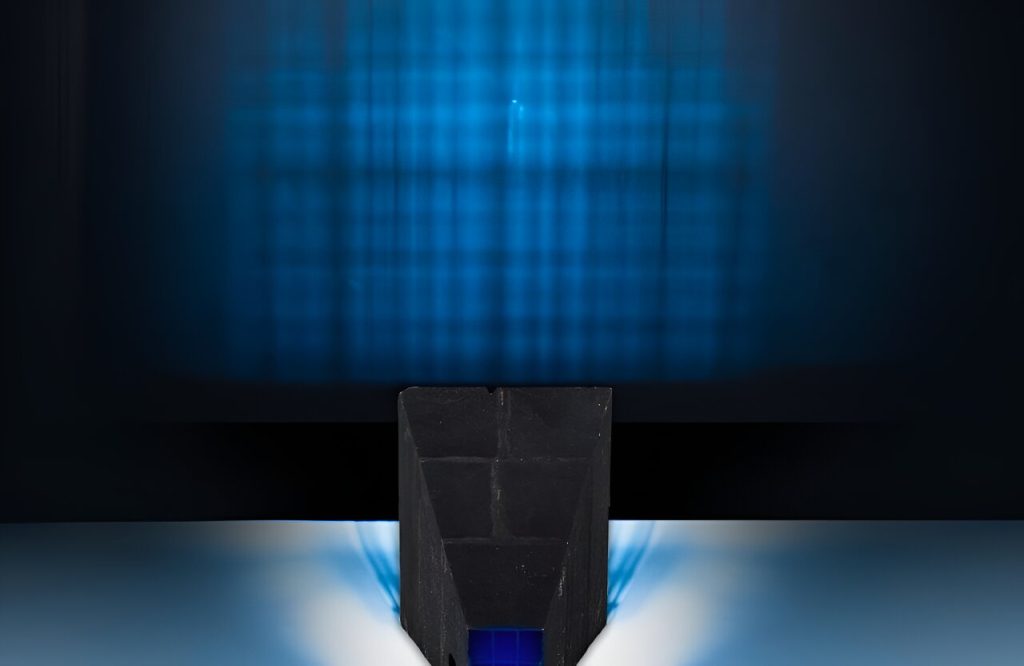

Optimized for studying material measuring well below 1 mm3, the team assessed their neutron collimator with a small sample contained within a high-pressure neutron diamond anvil cell.

Measured with a high-pressure instrument called the Spallation Neutron and Pressure beamline (SNAP), the collimator performed well during testing. As such, the researchers believe that their 3D printing approach could be used to produce these devices in real-world applications in industries such as medicine and nuclear energy.

The team’s findings have been published in the latest edition of the journal Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment.

What are neutron collimators?

Neutron collimators play a key role in neutron scattering, funneling the desired neutrons to a detector after they have interacted with sample materials. Significantly, these devices filter out stray neutrons that may have scattered off sample holders and other experimental apparatus, which could harm data collection.

Collimators feature numerous channels, the walls of which are called blades. During neutron scattering, unwanted neutrons enter these channels at oblique angles and are subsequently absorbed by the blades.

According to Fahima Islam, the study’s lead author and a neutronics scientist at ORNL’s Spallation Neutron Source (SNS), researchers are increasingly working to measure smaller material samples in more complex environments. These challenging conditions result in “a larger number of neutrons that did not interact with the sample and are not scattering from the sample.”

Therefore, to increase the accuracy of neutron scattering for smaller samples, the ORNL sought to 3D print a collimator that could be customized to filter out unwanted interference during different neutron scattering experiments.

3D printing optimizes neutron scattering

Due to the high number of neutrons which scatter when measuring small samples, the ORNL team needed to produce a large and highly accurate collimator. In their first attempt, the researchers scaled up an existing design, 3D printing a single-piece collimator measuring around 12 x 9 x 9 inches and including continuous front-to-back blades.

However, this approach impaired the precision of the 3D printed part, making it unsuitable for neutron scattering. What’s more, manufacturing the device as a single piece caused it to crack, due to variations in the materials contraction rate as it cooled.

“Simply scaling up the print as one large part with continuous blades was clearly not feasible without further optimizing the printing process,” explained study co-author Garrett Granroth.

As a result, the researchers next 3D printed an alternative multi-part design. The smaller 3D printed sections cooled more uniformly than the larger device, reducing the risk of cracking. This new design also featured blades which became progressively tighter throughout the body of the collimator, allowing for a higher density of blades and reducing the size of the channels.

To test the performance of their 3D printed device, and its suitability for neutron scattering with small samples, the researchers assessed a sample volume with a diameter of 1 mm and a height of 0.2 mm.

To push the collimator to its limits, the sample was placed inside a neutron diamond anvil cell, a high-pressure chamber that uses diamonds to apply intense pressure to the measured material.

“High-pressure cells are some of the most complex environments used in neutron experiments, so it is a real challenge to filter out the huge amount of unwanted cell scatter they produce,” stated Bianca Haberl, the study’s corresponding author and a neutron scattering scientist at SNS.

Ultimately, experimentation highlighted an extreme sensitivity to the collimator’s alignment and emphasized the importance of high precision when manufacturing and positioning the device. Once it was precisely aligned, the researchers found that their 3D printed neutron collimator performed well, enabling optimal results during neutron scattering.

Looking to the future, the ORNL team believe their design could be further improved with more stringent quality control and improved alignment.

Optimizing collimators with 3D printing

ORNL’s work on 3D printed collimators began with the development of a method for 3D printing B4C material.

Back in 2019, it was announced that binder jet 3D printer provider ExOne had licensed this additive manufacturing method from the Lab. At the time, this approach was viewed as an unconventional and promising process for the production of collimators, and other components for shielding equipment or neutron scattering instrumentation.

ORNL’s 3D printing method for B4C was first developed on an ExOne M-Flex binder jetting system. Once an object has been 3D printed in the material, it is then infiltrated with aluminum, to create a metal-ceramic composite, also known as a cermet. This combination can produce objects that are lightweight, strong, and capable of absorbing energy, ideal properties for collimators.

Elsewhere, Scientists from London’s Institute of Cancer Research (ICR) and the Royal Marsden Hospital added 3D printed tungsten collimators to a gamma camera to achieve higher-resolution medical imaging. These cameras capture traces of radiation emitted by injected pharmaceuticals within cancer patients to produce functional scans of the brain, thyroid, lungs, liver, gallbladder, kidneys and skeleton.

In the study, the UK-based researchers replaced conventional lead components with 3D printed tungsten collimators, which proved to be much more effective at eliminating unwanted radiation. This ultimately allowed for the creation of clearer final images.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows the team that developed the 3D printed collimator including, from left, Fahima Islam, Bianca Haberl and Garrett Granroth. Photo via Genevieve Martin/ORNL, U.S. Dept. of Energy.