Researchers from Stanford University have 3D printed nanoparticles that possess unique shapeshifting capabilities.

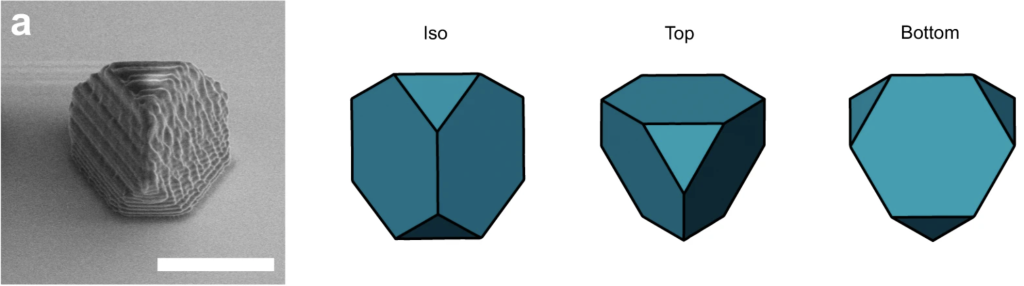

Called Archimedean truncated tetrahedrons (ATTs), the 3D printed shapes have long been recognized for their potential to form new materials that can instantaneously change form. However, they are especially hard to fabricate with conventional manufacturing techniques.

“We’ve used a 3D nanoprinting technique to produce one of the most promising shapes known – Archimedean truncated tetrahedrons. They are micron-scale tetrahedrons with the tips lopped off,” explained Wendy Gu, an assistant professor of mechanical engineering at Stanford University and lead author of the study.

Once 3D printed, the microscale particles successfully self-assembled into different crystal structures. It is believed that these materials could shift between phases in a matter of minutes by applying different external stimuli, similar to the atomic arrangement that creates tempered steel from iron.

It is hoped that these findings, recently published in the journal Nature Communications, could enable significant innovations in engineering and materials science applications.

For instance, the 3D printed nanoparticles could be used to develop solar panel coatings that change throughout the day to increase energy efficiency, hydrophobic films that prevent airplane windows and wings from fogging or icing up, or new computer memory systems.

“If we can learn to control these phase shifts in materials made of these Archimedean truncated tetrahedrons it could lead in many promising engineering directions,” added Gu.

3D printing shapeshifting nanoparticles

Researchers have long theorized that ATTs are one of the most effective geometries for the production of materials with phase-shifting capabilities. Successfully created in computer simulations, these structures have posed challenges in terms of physical fabrication.

While the Stanford team is not the first to fabricate large quantities of nanoscale ATTs, they are among the first to achieve this with 3D nanoprinting. During the study, the researchers leveraged two-photon lithography to fabricate approximately 50,000 particles on a Photonic GT 3D printer from microfabrication firm Nanoscribe.

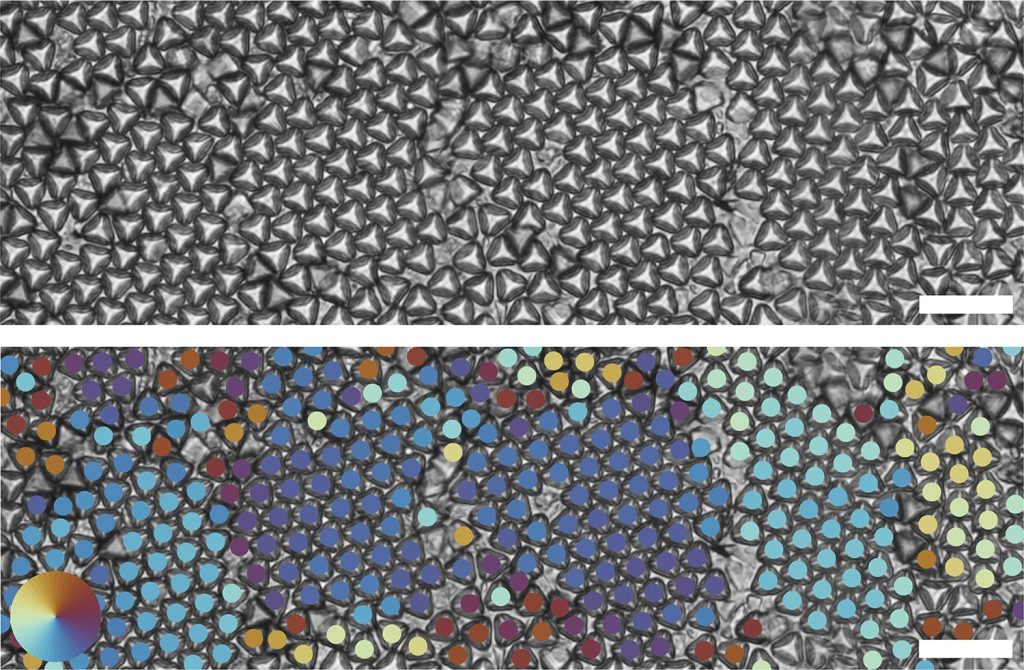

Once 3D printed, the nanoparticles were mixed into a water solution and then placed in a well plate. The researchers then observed how these nanoparticles self-assembled into two distinct geometric structures when tilted at 5° and 10° angles, respectively.

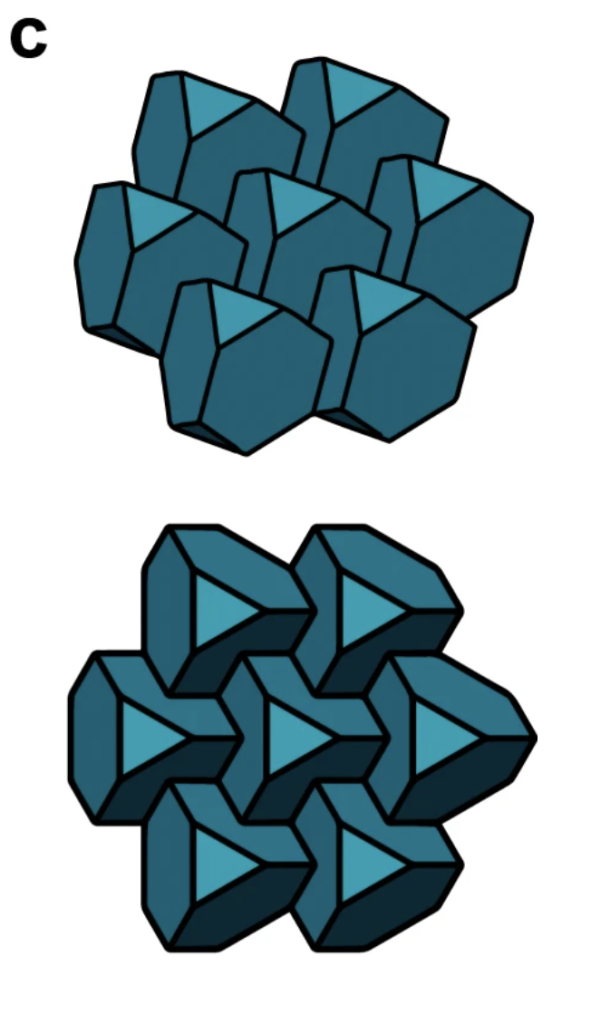

Firstly, a hexagonal pattern with the tetrahedrons resting flat on the substrate with their triangular face pointing upward was formed. According to the researchers, this is the first time this particular hexagonal phase has been reported in literature relating to ATTs.

The second structure, a crystalline quasi-diamond formation, is said to be more promising. Here, the ATT particles formed into alternating upward- and downward-facing orientations. This structure is an especially sought-after configuration within photonics research, with the Stanford team believing it could unlock novel scientific advances.

The team believes that adding external stimuli such as a magnetic field, electric currents and heat could enable the 3D printed particles to rapidly rearrange and change between phases. It is believed that such capabilities could offer significant value for a range of industrial applications in verticals such as aerospace, energy, and electronics.

The researchers are now exploring how to leverage ATTs in new ways. “Right now, we’re working on making these particles magnetic to control how they behave,” added Gu. “The possibilities are only beginning to be explored.”

Research into nano-scale 3D printing

This research is not the first to consider the role of nano 3D printing for the production of particles that can self-assemble into complex geometries.

Back in 2020, a team from the Karlsruhe Institute of Technology (KIT) developed a 3D printing ink for two-photon lithography that is capable of self-assembly. The team leveraged a specially formulated photoresist to fabricate self-assembled geometries in high volumes at rapid speeds.

The material was formulated to arrange itself into nanoporous structures with pore sizes ranging from 30 to 100 nm. To assess the material, the team 3D printed a hollow Ulbricht sphere with a diameter of 800 microns. It was found that the distribution of the pores could be controlled by varying the intensity of laser pulses, impacting the light scattering properties of the sphere.

The team noted that these microstructures could be combined to form larger, more complex structures which can be changed at will by varying the individual self-assembly profiles and 3D printing parameters.

Elsewhere, researchers from the Technical University of Hamburg (TUHH), the Massachusetts Institute of Technology (MIT), and Bremen University leveraged nano 3D printing to assemble particles into strong microstructures.

The team developed a direct-write self-assembly technique, which was reinforced with cross-linking, to bolster the strength of microstructures. It is believed that combining 3D printing with this colloidal assembly method could lead to the development of robust multifunctional 3D structures, offering value for aerospace applications.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Optical images of truncated tetrahedrons forming multiple hexagonal grains. Image via David Doan & John Kulikowski.