A team of researchers from the Karlsruhe Institute of Technology (KIT) have developed a novel photoresist, a printing ink for two photon lithography, capable of self-assembly.

As such, the material can be used to 3D print polymer microstructures with nanoscale porosities, producing a sort of lightweight nanofoam. By varying the printing parameters, the light scattering properties of the photoresist can also be closely controlled. The team believes its new material could have major implications for the manufacturing of microoptics, metamaterials, and even microscaffolds for bioprinting experiments.

Self assembly and 3D printing

The concept of self-assembly is an abstract one, and describes the way in which individual particles can be programmed to assemble themselves into complex synthetic geometries. This is usually limited to a relatively small spatial scale, however, so previous attempts to manufacture such structures on a more human scale have been met with failure.

Seeing an opportunity to employ 3D printing here, the KIT researchers thought to combine the two processes to produce these self-assembled geometries (the smaller nanocavities) in high volumes at rapid speeds. They could then be used to form the basis of even larger, more complex structures (the greater microstructures) which can be functionalized at will simply by varying the individual self-assembly profiles and certain printing parameters.

Nanocavities in the photoresist

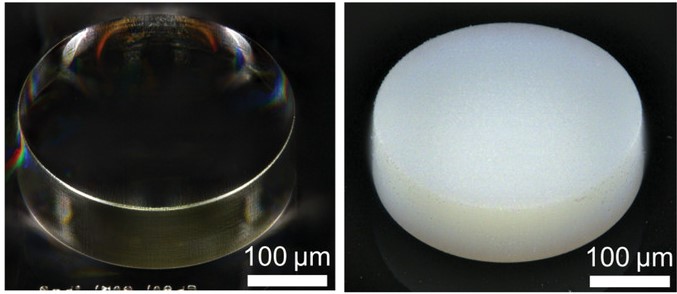

Conventional 3D printing photoresists are usually only ever capable of printing glassy, transparent polymers due to the laser’s need to penetrate the surface of the material during the fabrication process. Therefore, according to Frederik Mayer, main author of the study, there has never before been a photoresist with which an opaque white 3D structure could be printed.

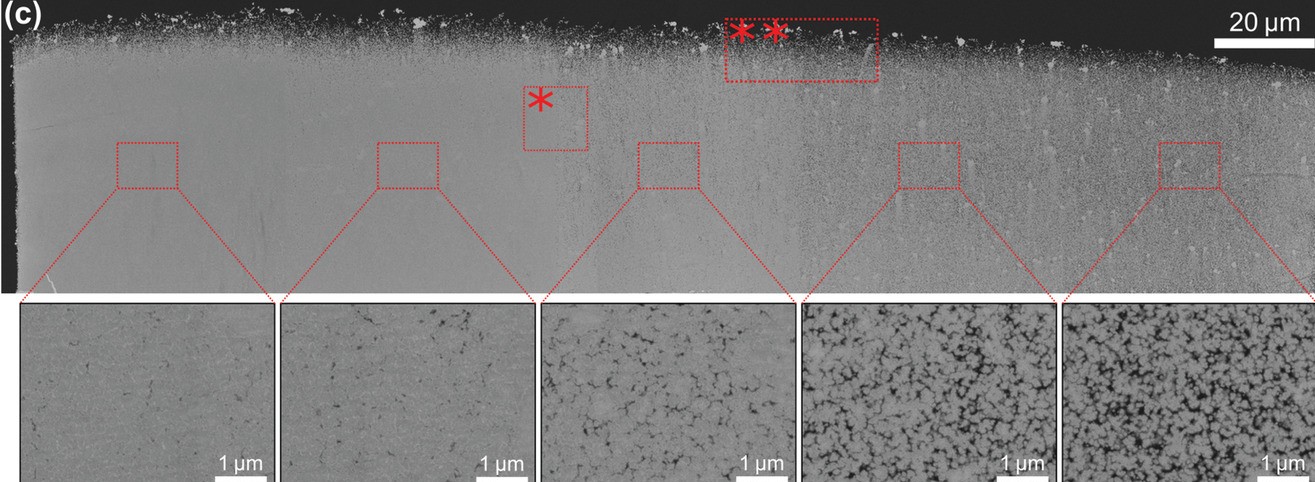

Operating on the self-assembly phenomenon, the team’s specially formulated photoresist was capable of arranging itself into nanoporous structures with pore sizes in the 30 to 100nm range, all filled with air. Much like a porous eggshell, the nanocavities in this photoresist made it appear white in the presence of light, almost like a miniature hall of reflective mirrors. So, despite it being transparent prior to printing, the material could be used to produce reflective white surfaces.

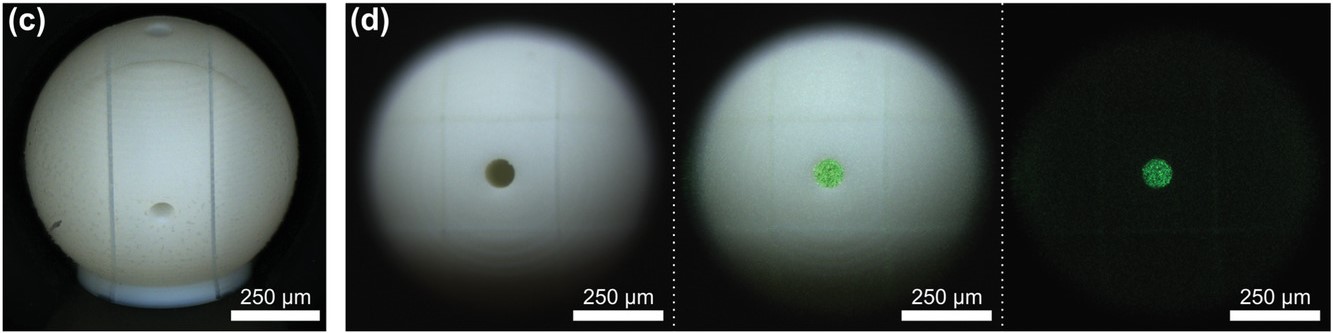

Utilizing a commercial two-photon lithography machine – Nanoscribe’s Photonic Professional GT – the team put their novel photoresist to the test with the 3D printing of a hollow Ulbricht sphere just 800 microns in diameter. With electron microscopy scans, they found that the distribution of the pores could be controlled by varying the intensity of the laser pulses, subsequently affecting the light scattering properties of the sphere for microoptics. It was also determined that the large internal surface areas of the structures could be great for micro-filtration applications, hydrophobic coatings, and even tissue engineering with small cell cultures.

Further details of the study can be found in the paper titled ‘3D Two‐Photon Microprinting of Nanoporous Architectures’. It is co-authored by Frederik Mayer, Daniel Ryklin, Irene Wacker et al.

Just last month, Vienna-based polymerization specialist UpNano launched a novel two-photon technology utilizing a high-power laser. The part serves to speed up the printing process with nano and microscale resolutions across 12 orders of magnitude, enabling small part fabrication down to the micrometer. Elsewhere, Nanoscribe has previously joined MiLiQuant, an ongoing three-year project to develop diode laser-based light sources for 3D printing and imaging at the quantum level.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the photoresist printing process. Image via KIT.