A team of researchers from Zhejiang University and De Montfort University have 3D printed a multi-layer drug delivery device (DDD) capable of delivering more than one drug to different parts of the gastrointestinal system. With its characteristic core-shell geometry, the DDD can be loaded with different medicines for a variety of slow and fast release profiles. The researchers believe their work has the potential to greatly benefit the microbial ecosystems found in human beings by combating E. coli, citing applications in probiotics.

‘Good’ vs ‘bad’ bacteria

The guts of human beings are home to a whole host of microorganisms. These gut microbes can have a profound effect on our nutrition and general health. With such a delicate balance between ‘good’ and ‘bad’ bacteria, a slight tip of the scales can lead to a number of health problems such as obesity, allergies, and even cancer. In fact, there is a whole industry dedicated to edible probiotics – yogurts and tablets containing live cultures of beneficial microbes. Take it with your main meal and you can send in the cavalry to win the war taking place in the darkness.

3D printing a multi-drug delivery system

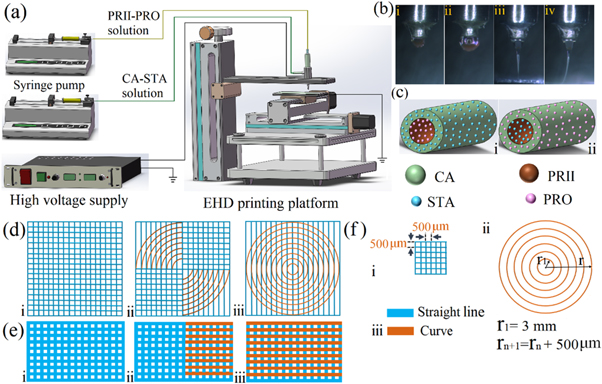

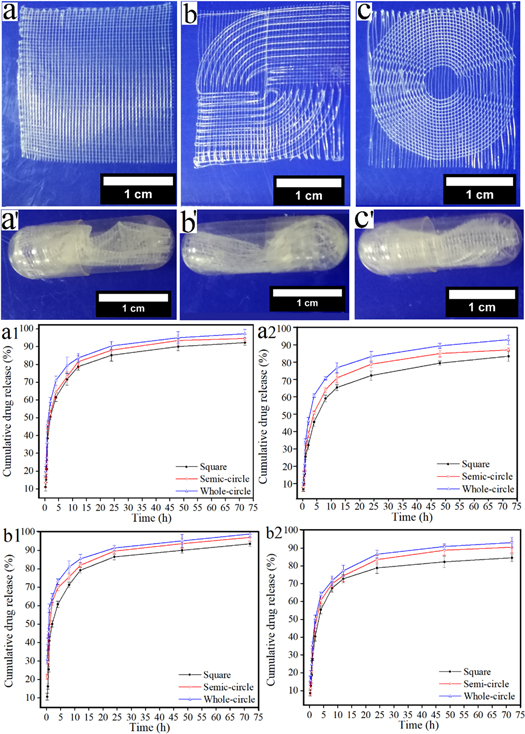

The team used an electrohydrodynamic 3D printer to fabricate the core-shell structure fibers. The machine allowed them to precisely stack and align fibers at the nanoscale to develop complex structures. This way, the geometries of the DDDs could be personalized with release profiles suitable for different patients. The researchers printed a square, a whole circle, and a semi-circle for the study. In each of the DDDs, proteoglycan was stored in the core layer (polyacrylic resin II) and stachyose was stored in the shell layer (cellulose acetate).

The team tested the DDDs in simulated gastrointestinal fluids, determining their release rates and tensile strengths. The shell layers dissolved within 12 hours but the core layers remained intact for a maximum of 72 hours – plenty of time for the DDDs to make their way into the depths of the intestines. The maximum tensile strength (the whole circle) was determined to be greater than 0.22MPa, which is the pressure found in the human gut.

The DDDs were successful in raising the proliferation ratio of Bifidobacterium bifidum (good bacteria) to 294.2%. On top of this, the DDDs were found to have a significant inhibition effect on E. coli (not so good bacteria), with a maximum of 37%. In light of the promising results, the researchers concluded that the core-shell structures they had developed could be extremely useful in rebalancing the gut flora in human beings.

Further details of the study can be found in the paper titled ‘A core–shell multi-drug platform to improve gastrointestinal tract microbial health using 3D printing’. It is co-authored by Li-Fang Zhu, Xing Chen, Zeeshan Ahmad, Yu Peng, and Ming-Wei Chang.

The 3D printing of drug delivery devices and the effects of their geometries is a long researched topic. Earlier this year, researchers from Greece and Italy explored the use of 3D printing as a coating technology for developing custom release rates in oral delivery devices. In this case, the tablets themselves were produced using traditional methods but the coatings were extruded post-production, demonstrating an alternative application of the technology. Elsewhere, in the UK, researchers have 3D printed a triggerable and remotely controllable drug delivery device. Through the use of an integrated macroscale magnetic field, the device can be used to provide precise, on-demand dosages to patients.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

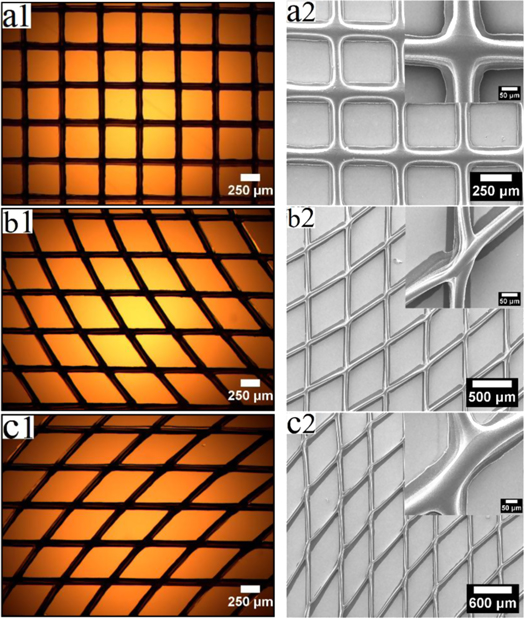

Featured image shows SEM imaging of the DDD fibers. Image via DMU.