Researchers from the University of California, Davis (UC Davis) have published a paper detailing a new approach to 3D printing using microfluidics, led by chemical engineering assistant professor Jiandi Wan.

The new technique uses a droplet-based, multi-phase microfluidic system to efficiently 3D print finely-tuned flexible materials. It allows the user to manipulate the extruded ink composition and properties in real time, enabling the fabrication of diverse and functional structures with varied compositions and properties. The researchers see potential applications for the technology in soft robotics, tissue engineering and wearable technology.

Droplet-based 3D printing using microfluidics

The researchers begin by explaining that while 3D printing technology may aim to “seamlessly vary composition and functional properties in printed constructs. Most inks used for extrusion based printing, however, are compositionally static and available approaches for dynamic tuning of ink composition remain few.”

Indeed, with traditional extrusion-based 3D printing technology, material is pushed through a nozzle and added to the structure repeatedly, layer-by-layer, until the product is complete. Although an efficient and cost-effective process, it makes it hard to print structures made of more than one material and getting the right amount of softness can be a challenging process.

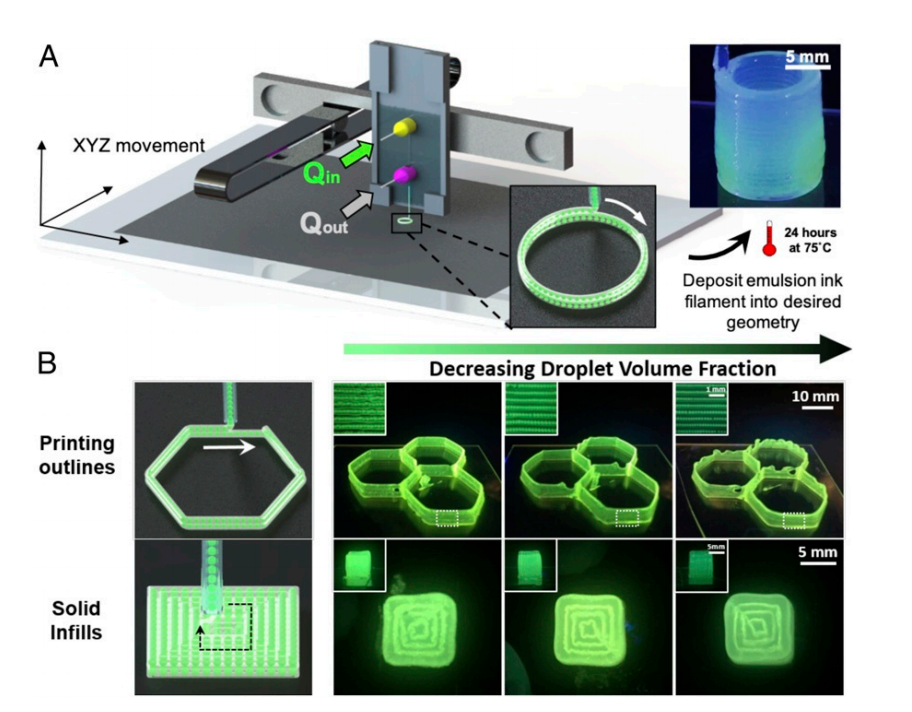

As such, Wan’s group sought to create an approach for extrusion-based 3D printing that allowed the modulation of extruded inks at the point of print, using droplet inclusions. The researchers noticed that the nozzle used in extrusion-based 3D printers is similar to the glass capillary microfluidic devices that the team had been studying. These devices use multiple nozzles place within each other, realized it could be adapted for 3D printing, to be used as the printhead: “Most extrusion-based 3D printers use very simple nozzles and since we had already developed these glass microfluidics, we thought, ‘why not apply it to 3D printing?’” explains Wan.

Wan’s team developed a device that uses a multi-phase drip system to encapsulate droplets of an aqueous polyethylene glycol diacrylate (PEGDA) solution inside of a common silicon-based organic polymer called polydimethylsiloxane (PDMS). The PDMS flows around a dripper, creating tiny droplets of the PEGDA which are then evenly inserted into the PDMS as both materials flow onto the 3D printed structure as it is fabricated.

The final structure is described as looking like a “Pac-Man maze” with tiny dots of PEGDA droplets surrounded by PDMS. After the PEGDA diffuses out of the droplets, it interferes with the polymerization process of PDMS, causing the material to soften and making the structure more flexible.

Wan’s research team also demonstrated that the droplet-based 3D printing method can be used to produce flexible porous constructs with encapsulated polymer particles and metal droplets. Furthermore, the structure flexibility can be modified by altering the droplet size and flow rate. This provides researchers with a wide range of choices to design their material structure and vary flexibility to the intended application, in a way that’s difficult with standard nozzle-based methods.

“The mechanical characteristics of the 3D-printed constructs can be tuned in situ by varying the spatial distribution of droplets, including aqueous and liquid metal droplets,” explain the authors in the paper.

Microfluidics in 3D printing

Microfluidics generally refers to the technology of fluid manipulation in channels with dimensions of tens of micrometers. 3D printing based on microfluidics is not a new concept, with various systems and processes utilizing the technology. Indeed, in 2019 European researchers produced a review on 3D printing microfluidic applications, which they state will “Ultimately allow the creation of a new generation of increasingly smart, responsive, and autonomous devices, able to sense and act upon their environment in complex ways and with reduced human intervention.”

For example, the Singapore University of Technology and Design‘s (SUTD) Soft Fluidics Lab developed a simple method to 3D print microfluidic devices integrated with fluid handling and functional components in August 2019.

Furthermore, in March 2018, researchers from New York Genome Center (NYGC) and New York University (NYU) created an open-source, bedside 3D printed droplet microfluidic control instrument. The device represents a cheap, accessible method for identifying and targeting the correct cells to treat diseases like Rheumatoid Arthritis (RA).

The study discussed in this article, “On-demand modulation of 3D-printed elastomers using programmable droplet inclusions,” is published in the Proceedings of the National Academy of Sciences of the United States (PNAS).

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

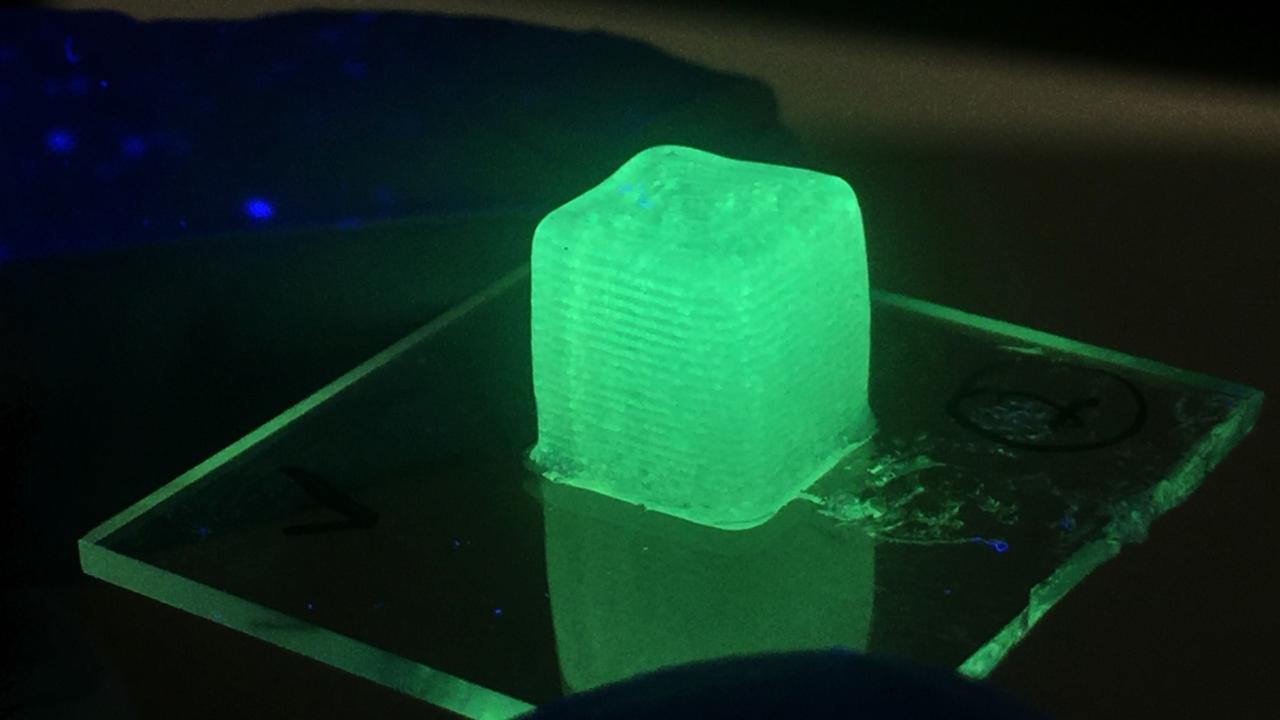

Featured image shows Material printed with the Wan Lab’s new droplet-based 3D printing method. Photo via Jiandi Wan.