Researchers in the UK and the U.S. have developed a 3D printed device with a triggerable and remotely controllable system for on-demand drug delivery using an integrated macroscale magnetic field.

With the growing demand for personalized medicine and medical devices, the researchers explain that on-demand triggerable drug delivery systems via magnetic fields have increased significantly in recent years. 3D printing technology itself has already been applied numerous times in the development of personalized dosage forms, due to its high-precision and accurate manufacturing ability.

Combining the two technologies, the researchers aimed to create a triggerable drug delivery device that can provide a safe, long-term, and reusable method for localized disease treatment for conditions and diseases such as cancer. To illustrate the drug release behaviour of the device, an anti-cancer substance was used as the model drug successfully, which they describe in their research paper.

Advantages of drug delivery systems

The purpose of drug delivery systems, explain the authors of the study, are to “provide predetermined drug release profiles ensuring optimal distribution and absorption of pharmaceutical compounds, which enhance therapeutic effectiveness and minimize side effects by offering a safer, more convenient, and efficient drug administration in humans with enhanced patient compliance.”

The use of drug delivery systems can potentially enable predetermined drug release profiles that can enhance efficacy, safety, and patient compliance, However, the researchers explain that it has been difficult for conventional drug delivery systems to maintain drug concentration levels that avoid ineffectiveness (underdose) or toxicity (overdose) within the narrow window for the therapeutic range of a drug. As such, it is important that drug delivery systems are designed to modulate drug release in terms of time, rate, and location which, according to the researchers, would “show considerable advances in delivering drugs, like painkillers, hormones, and chemotherapeutic agents.”

The field of personalized medicine has attracted a great deal of attention in recent years as it has the ability to provide patients with “a superior treatment with a comprehensive consideration of their own pharmacogenomics, anatomical, and physical conditions,” the researchers write. There has been an increase in demand for a tailored method of dosage forms to suit patients due to inappropriate dosing or dosage combinations, which has caused various adverse effects from drug therapy.

3D printed drug delivery systems

To address these challenges and fulfil the demands of personalized medicine and pharmaceutical dosage forms, 3D printed drug delivery systems have been used and developed for various applications successfully in place of traditionally manufactured drug delivery systems. This is due to the precise manufacturing capabilities of 3D printing technology, as well as its compatibility with complex materials, according to the researchers: “This technology can achieve detailed and flexible spatial composition, and provide more available starting materials (like colloidal inks, bio-inks, and polymers) for the unprecedented complex and precise manufacture of 3D DDSs. Various techniques, namely powderbased (PB), stereolithography (SLA), selective laser sintering (SLS), inkjet printing and fused deposition modelling (FDM) have been explored in the pharmaceutical applications.”

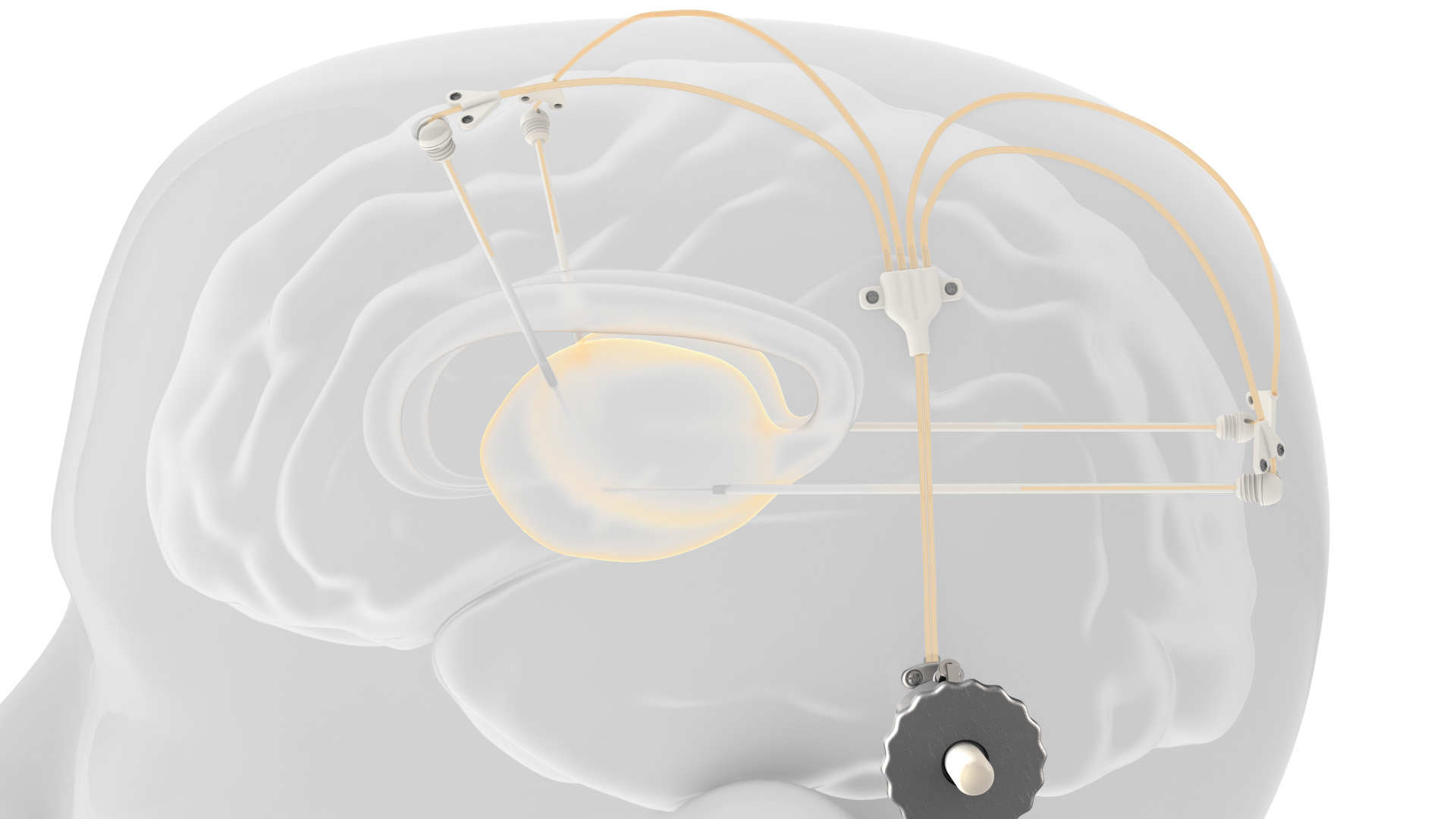

Indeed, a recent special issue editorial by scientists from Queen’s University Belfast explores the production of pharmaceuticals and drug delivery devices using a variety of 3D printing technologies. The paper aims to explore the ways in which drug delivery can benefit from 3D printing. Recent advancements in the field of 3D printed drug delivery devices have come from the likes of Renishaw, which initiated a medical study seeking to help sufferers of Parkinson’s disease, with an implant that delivers cerebral dopamine neurotrophic factor to affected areas of the brain.

Controlling drug release profile using magnetic fields

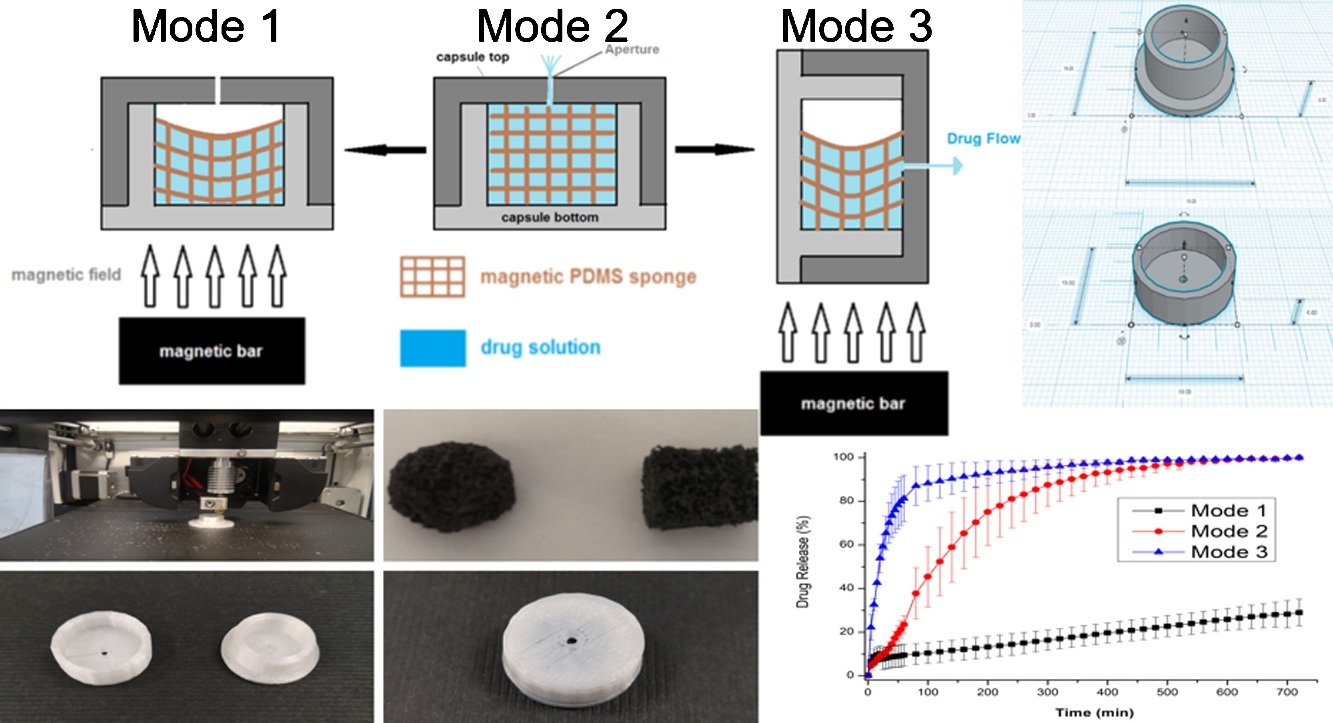

In particular, the researchers highlight FDM 3D printing for use in developing drug delivery devices due to its “cost-effective, time-saving and versatile modalities of producing sophisticated solid objects.” With this in mind, the researchers set about creating a drug delivery system that can achieve highly precise and dynamic administration of drugs in an active and instant manner. They did this using a magnetic-field triggerable drug delivery system with an FDM 3D printed reservoir and magnetic polydimethylsiloxane (PDMS) sponges.

The researchers designed the reservoir using Solidworks, and then 3D printed it in PLA using a Robo R2 FDM system. They then fabricated porous magnetic sponges, which were designed to fit the shape of the hollow space of the reservoir at the bottom. Before being placed in the 3D printed device, the researchers immersed the sponge cylinders in the model drug solution, 5-fluorouracil (FLU), before closing the two parts of the reservoir tightly. The researchers were able to measure the amount of drug loaded into the device by weighing the apparatus before and after.

Using a magnetic bar and performing a number of successful tests, the researchers found that they were able to actively control the drug release of the device by controlling the magnetic field, due to the shrinking extent of the macro-porous magnetic sponge inside. When placing the bar on the side of the device, 50 percent, 80 percent and 90 percent of the drug was dissolved at round 20, 55 and 140 minutes, respectively. This position was termed as the “on” state by the researchers. In contrast, the switching “off” state of drug-releasing could be realized by the magnetic bar placed at the bottom of the device as only 10% percent of the drug could be released within 12 hours.

Concluding the paper, the authors write: “This device has the potential to be optimized as a safe and long-term implant because of its large drug loading ability. It can be the key component of a multi-functional, implantable and smart drug delivery system for the controlled release of therapeutic substances to avoid frequent injection or various sophisticated dosing regimens.”

This paper, “Novel 3D printed device with integrated macroscale magnetic field triggerable anti-cancer drug delivery system,” is published in Colloids and Surfaces B: Biointerfaces. It is written by Kejing Shi, Rodrigo Aviles-Espinosa, Elizabeth Rendon-Morales, Lisa Woodbine, Mohammed Maniruzzaman and Ali Nokhodchia.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows graphical abstract of research on 3D printed drug delivery device. Photo via Colloids and Surfaces B: Biointerfaces.