In a development reminiscent of science-fiction, microscopic, 3D printed ships have proved capable of treating damaged brain tissue.

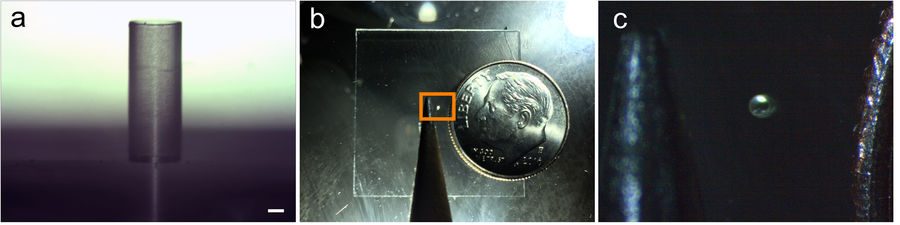

The latest device to seemingly receive shrink-ray treatment is the Biocage – a porous cylinder resembling a rudimentary rocket, or a bullet.

The Biocage has been made in a project led by researchers at George Washington University (GWU), with the collaboration of the University of Maryland, the Children’s National Medical Center, Virginia Tech, Brown, and Yale.

Through tests in mouse brains, Biocages have been demonstrated as “a powerful tool for local and precise therapeutic [drug] delivery.”

An alternative for serious illnesses

The power of new pharmaceutical developments like the Biocage lies in their potential to target areas of the body and treat specific, often rare, illnesses and diseases.

3D printing, typically on a microscopic scale, has been applied in a number of projects aiming to advance the possibilities of patient care. Using 3D nanolithography, a team at IFW Dresden and Chemnitz University of Technology created tetrapod sheaths for sperm that could be used to treat gynecologic cancers.

Similarly, a team at the Max Planck Institute for Intelligent Systems in Stuttgart made an army of drug-filled “microswimmers” that could be used to target sites of infection and disease.

Microscopic fabrication

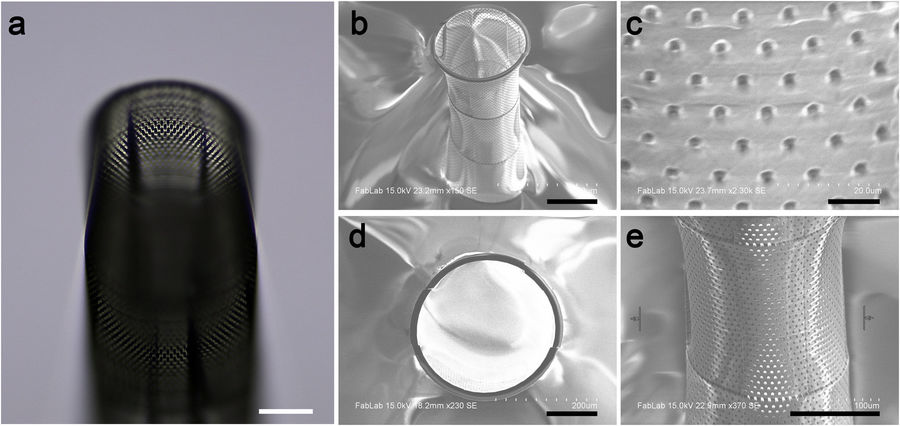

GWU’s Biocage is made using a Nanoscribe Photonic Professional GT 3D laser lithography system, a two-photon polymerization 3D printer that the project has in common with the Max Planck Institute and other institutions including Oak Ridge National Laboratory (ORNL).

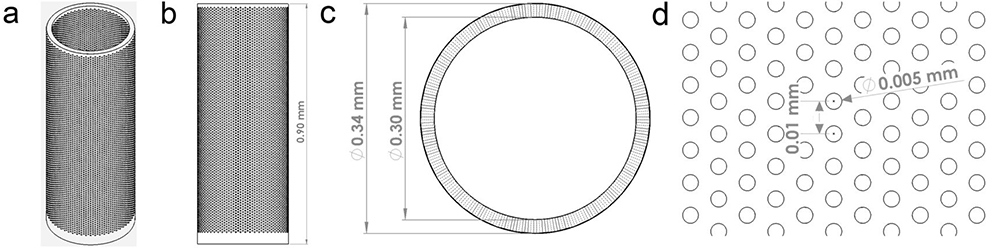

Pores in the body of the Biocage are 0.005 mm in diameter, and a single cage capsule measures just 0.90 mm in length.

They are made from modified IP Photoresist material which is designed to give high resolution and structure stability on a small scale.

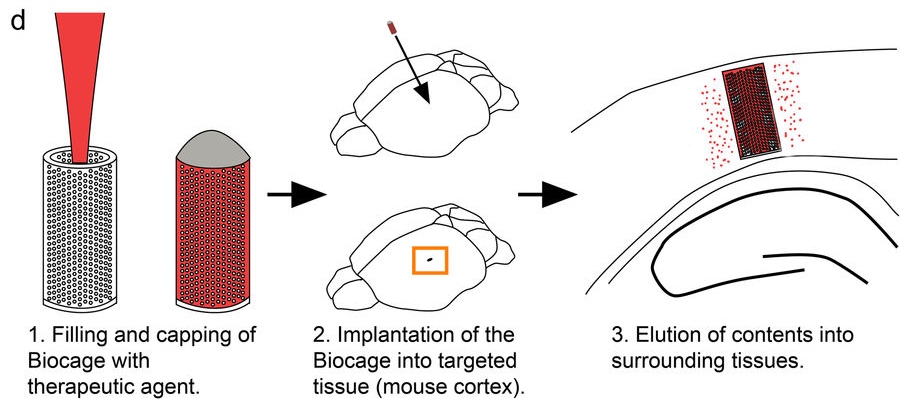

Once 3D printed the Biocage is filled with an active substance, and sealed with a cap.

Biocages on the brain

GWU scientists first tested the capsules using a fluorescent liquid – enabling them to see how liquid is released from the Biocage inside the brain.

In another test, capsules were filled with a mixture of agarose and biocytin, a chemical compound that naturally occurs in blood serum and urine. According to results published in Scientific Reports, “Biocytin release was clearly observed in the areas surrounding the Biocage (…) the labeling of which was not observed in controls Biocages that were only loaded with agarose.”

The observed effects therefore demonstrated the fundamental ability of substance release in-vivo, into the brain of a healthy, living mouse.

Experiments with potential

Through further study of Biocages GWU and associate researchers hope to be able to help develop new therapies for conditions such as Parkinson’s disease, Alzheimer’s disease11, and epilepsy. According to authors, “this device may also provide a means of other therapies that have had faced certain technical limitations, including stem cell and gene therapies.”

“Given its potential,” the disucssion continues, “much research remains in terms of properly utilizing the Biocage for various therapeutic contexts.”

An Implantable Micro-Caged Device for Direct Local Delivery of Agents is available to read online here. It is co-authored by Alexander I. Son, Justin D. Opfermann, Caroline McCue, Julie Ziobro, John H. Abrahams III, Katherine Jones, Paul D. Morton, Seiji Ishii, Chima Oluigbo, Axel Krieger, Judy S. Liu, Kazue Hashimoto-Torii and Masaaki Torii.

To stay up to date with the latest developments in pharmaceutical 3D printing and more subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Nominate the best 3D printing related research team in the second annual 3D Printing Industry Awards here.

Featured image shows a Biocage design blueprint. Image via Scientific Reports.