Using nanoscopic 3D printing technology from Germany’s Nanoscribe GmbH, the Max Planck Institute for Intelligent Systems in Stuttgart has developed a strategy to make micromachines that can be controlled within the human body. Named ‘microswimmers’ these minute machines could be used for the precise drug delivery to sites of disease and infection.

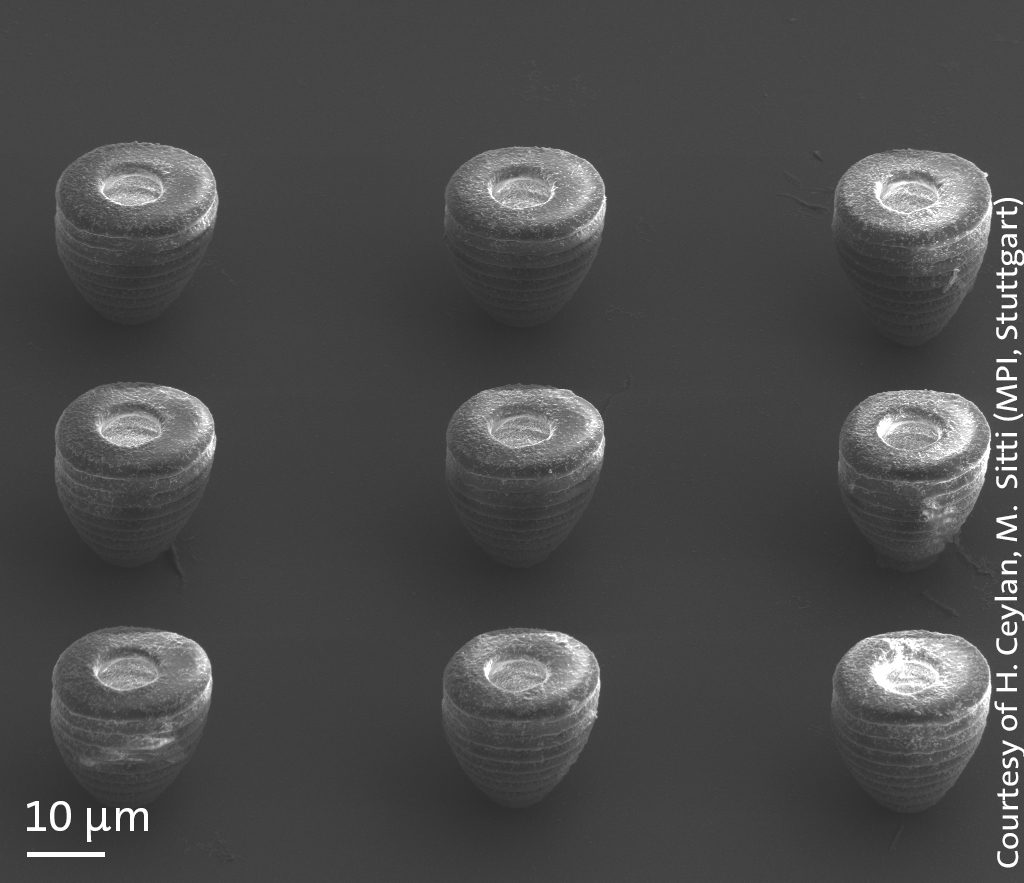

Tracking of the 3D printed microswimmers under a scanning electron microscope (SEM). Clip from supplementary video by the Max Planck Institute for Intelligent Systems.

Taking advantage of a chemical reaction

The microswimmers are made from a hydrogel, a soft material composed almost entirely of water. They take on a simple rocket-like shape that navigates with the point facing forward.

The “fuel” in these mini rockets is a chemical extracted from acrylic acid that mixes well with water. When combined with hydrogen peroxide, a compound found in the human immune system, these acids react, creating bubbles that propel the microswimmers in a particular direction.

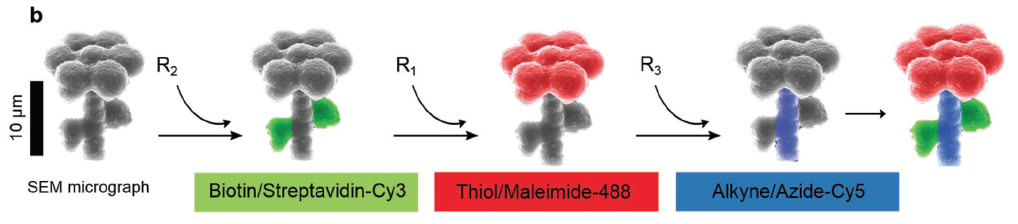

By exploiting the chemistry between these two substances, a reaction termed two-photon crosslinking, and applying 3D printing/design the researchers are able to control the microswimmers’ motion.

A batch of 3D printed microswimmers emitting propelling bubbles in a concentration of 2% hydrogen peroxide. Clip from supplementary video by the Max Planck Institute for Intelligent Systems.

A “new generation” of programmable materials

A full article on the microswimmers, titled 3D Chemical Patterning of Micromaterials for Encoded Functionality, has been published in Advanced Materials journal, Volume 29, Issue 9 and can be accessed online here. It is co-authored by Hakan Ceylan, Immihan Ceren Yasa and Metin Sitti.

3D printing in this research was performed by Nanoscribe’s 3D microprinter, the Photonic Professional GT, that uses light to cure liquids into a solid. In the introduction to the study, authors explain how this method could be used for practically any clear material that forms bonds when exposed to light, therefore,

paving the way to engineering a new generation of geometrically and chemically programmable, functionally active and passive materials in the microscale that can accomplish previously unconceivable complex tasks.

To further prove the advantages of this method, using 3D design and other materials, Max Planck researchers also demonstrate the ability to create a nanscopic flower made from a combination of vitamins.

Transforming medical research on the nanoscale

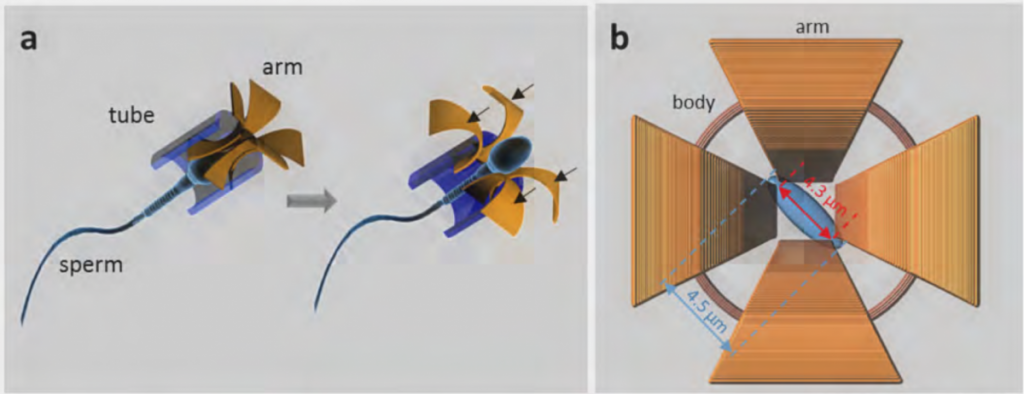

Nanoscribe’s 3D microprinter has also been used in microfabrication of devices that can promote mobility of sperm. Materials developed by Nanoscribe were similarly used by IFW Dresden and Chemnitz University of Technology in research to transform sperm into drug carriers to treat cancer.

The overall aim of such research, as explained by Ceylan, Ceren Yasa and Sitti in the microswimmers study, is to produce “a well-designed device of the size of a single cell with well-designed on-board sensing, actuation, and self-powering capabilities”. Once achieved, such devices could “provide an unprecedented direct access to deep and complex body sites, such as brain, spinal cord, and eye”.

The hope for the future is to be able to use micromachines to perform minimally invasive operations and controlled drug delivery within the human body. Though such functions are still far from actuality, researchers are paying much attention to nanoscale research, as in biotbot research at the University of Illinois Urbana-Champaign, and organ-on-a-chip technology.

For more of the latest 3D printing released research news sign up to the 3D Printing Industry newsletter, and follow our active social media sites.

Don’t forget to vote in the first annual 3D Printing Industry Awards.

Tickets for the 3D Printing Industry Awards are also now available here.

Featured image: Tracking of a 3D printed microswimmer under a Scanning Electron Microscope (SEM). Image via Advanced Materials, Volume 29, Issue 9 by Hakan Ceylan, Immihan Ceren Yasa and Metin Sitti of the Max Planck Institute for Intelligent Systems.