With an FFF 3D printer researchers at the University of Texas at Dallas (UT Dallas) now have a new low-cost method of making microneedle arrays – a small syringe-alternative patch for administering drugs.

The method combines a commercially available desktop 3D printer with a chemical etching technique. It enables the creation of ultra-fine microscopic pins in a range of medical materials currently unavailable to high-res 3D printing methods.

Pain-free jabs

Microneedle patches alleviate the pain and safety risks associated with the traditional method of delivering drugs using a syringe. They also have a longer shelf life than drugs made as injectable liquids. For these reasons, microneedles have become an integral part of new medical research, including efforts at Georgia Institute of Technology and Emory University to use the arrays as an alternative to flu vaccinations.

The primary breakthrough in the UT Dallas research is the manufacture of skin-piercing microneedles using an FDA approved biomaterial that dissolves over time.

Achieving these parameters at a low-cost would have been incredibly challenging with any other 3D printing technique.

Applying commercial FFF in medicine

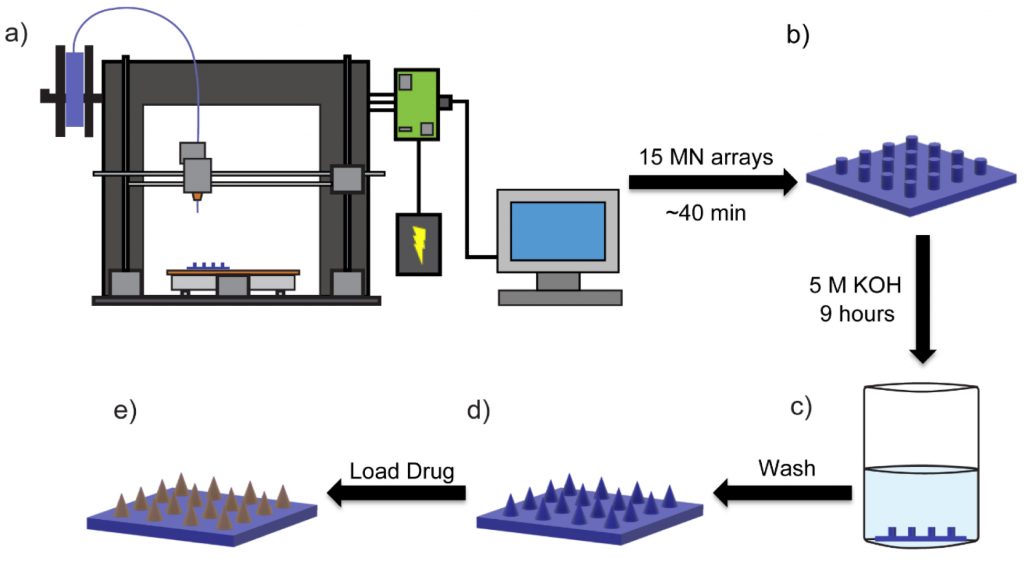

The UT Dallas team’s manufacturing method is a five step process that starts with FFF using a Lulzbot TAZ 5 3D printer. It takes 40 minutes on average to make a batch of 15 microneedle arrays.

The arrays are then left to soak in a chemical solution for 9 hours which etches the surface, and carves the microneedles to a fine point between 1 and 55 μm wide.

In the penulitmate step, the microneedles are washed. Then they can be loaded with a drug for application in the skin.

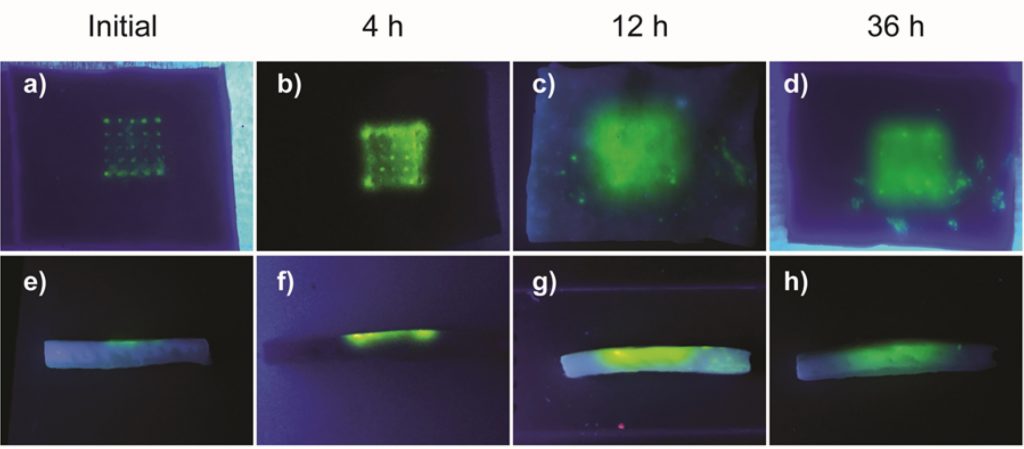

In this case, UT Dallas demonstrated the ability to apply a fluorescent dye under the skin using the 3D printed mironeedle patches.

A promising alternative in medicine

In other research, 3D printing has presented the potential for creating new ways of treating cancer, and controlling the release of multiple drugs through a single vaccination.

In summary of UT Dallas’ study, conclusions state, “we have developed a new chemical etching method that improves the feature size resolution of FDM printed materials allowing for the fabrication of biocompatible [microneedles] capable of penetrating the outer layers of skin and delivering a model therapeutic agent.”

Additionally, “Using our etching method […] biocompatible polyesters—which currently cannot be used with higher resolution printing techniques such as SLA— could now be applied in [microneedle] fabrication.”

“Biodegradable 3D Printed Polymer Microneedles for Transdermal Drug Delivery” is co-authored by Michael A. Luzuriaga, Danielle R. Berry, John C. Reagan, Ronald A. Smaldone and Jeremiah J. Gassensmith. The full paper can be accessed online in the Royal Society of Chemistry’s data repository ChemRxiv.

Stay up to date with all the latest 3D printing breakthroughs by subscribing to the 3D Printing Industry newsletter, following us on Twitter, and liking us on Facebook.

Find and post 3D printing jobs here.

Vote for research team of the year and more in the 2018 3D Printing Industry Awards. To be in with a chance of attending this year’s event, winning a 3D printer, and having your design 3D printed by Protolabs, enter the 3D Printing Industry Awards trophy design competition.

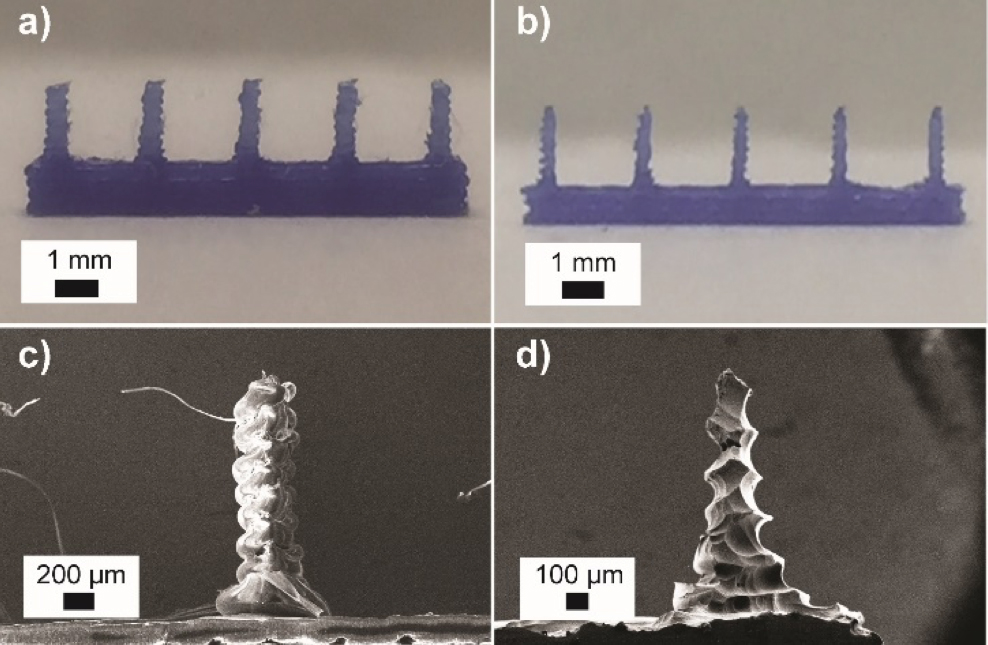

Featured image shows (a,c) 3D printed and (b, d) chemically etched microneedle arrays. Image via ChemRxiv