A team of researchers from the University of Hamburg has developed a novel 3D printing process for nanoparticle-based aerogels that could result in a new generation of photothermal devices.

Based on Direct Ink Writing (DIW) 3D printing, the technique offers new levels of design freedom for fabricating solar steam generation or thermochemical heat storage devices from titanium dioxide (TiO2) nanoparticle-based aerogels.

While TiO2 was used as the basis for the study, the researchers say their technique can also be generalized for a “broad material library” and allow nanoparticle inks to be designed with specific functionalities that can be adapted to their target applications.

Challenges of nanoparticle-based aerogels

Aerogels are highly porous solids that maintain the properties of individual nanomaterials at a macroscopic scale. While nanomaterials of various sizes, shapes, compositions, and surface chemistry with remarkable properties can be created, high-volume manufacturing of macroscopic nanomaterial-based devices remains a challenge.

One of the main difficulties of nanomaterial processing is the preservation of nanoscopic properties across multiple length scales. While gel casting provides an attractive approach for processing nanomaterials into aerogels, the restricted range of mold geometries available and the fact that aerogels created in this way have limited shape tunability, prevent complex microstructured geometries from being produced.

The researchers identified extrusion-based DIW 3D printing as a promising technique for overcoming these challenges, as the technology evolved from ceramic processing whereby materials and devices could be fabricated from preformed particles. However, ceramics and nanoparticle-based aerogels have fundamentally distinct properties due to differences in particle size and porosity.

As such, the researchers needed to formulate additive-free 3D printable inks, similar to conventionally cast aerogels, that were compatible with the DIW process in order to fully capture the nanomaterials’ properties within the 3D printed aerogel.

3D printing nanoparticle-based aerogels

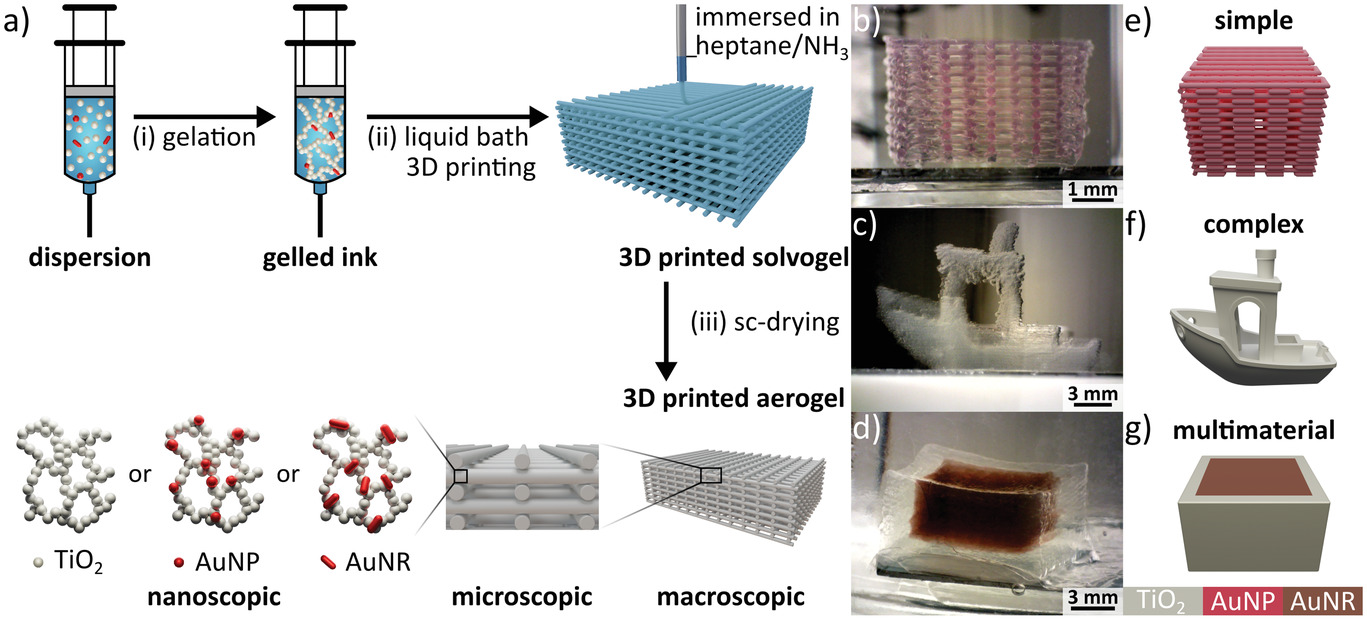

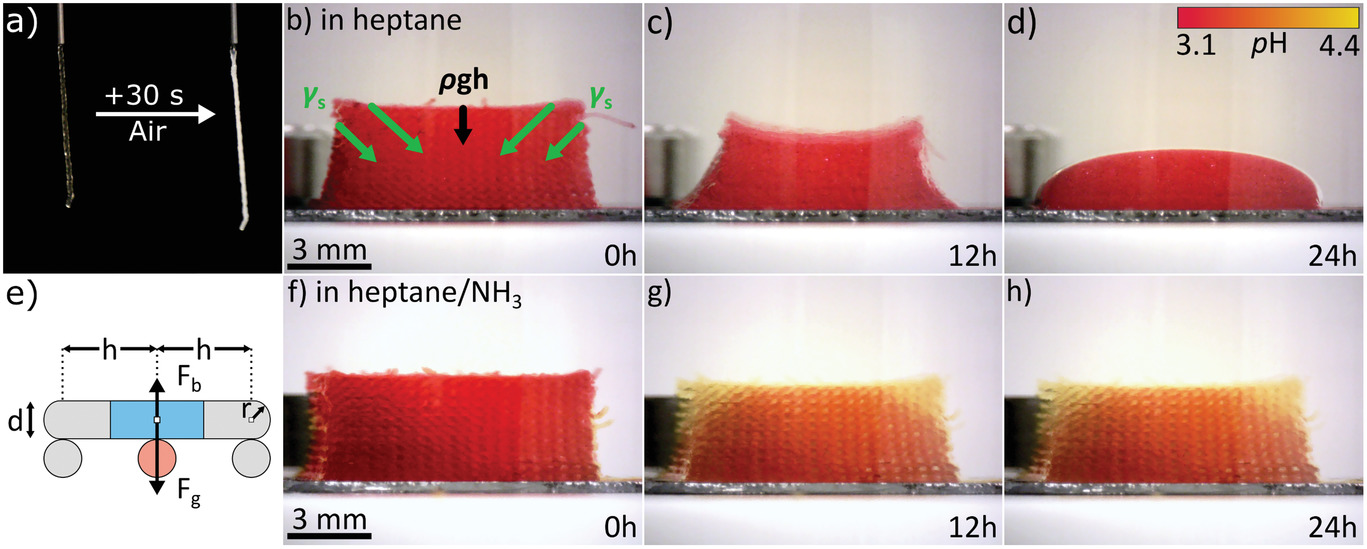

During the study, the researchers focused on developing a DIW 3D printing process capable of processing TIO2-based aerogels. Instead of using rheologic additives to ensure printability, which can be detrimental to the nanomaterial’s properties, the printing process took place in a liquid alkaline bath. This allowed the researchers to maintain the ink’s nanoscopic characteristics while also creating macroscopic translucent aerogel geometries.

The process started with forming an ink via nanoparticle gelation which was then 3D printed in the liquid bath before undergoing post-processing via supercritical drying. The researchers identified that inks loaded with a particle concentration of 4% volume were best suited for 3D printing. Leveraging an Engine HR 3D printer from Hyrel 3D, the 3D printing process was performed in a liquid bath in order to overcome the evaporation-induced gel damage observed when printing the nanoparticle-based aerogel in air.

Additionally, the researchers found that they could easily process multicomponent inks by mixing TIO2 with additional nanoparticles such as gold (AU) nanoparticles (AuNP) or Au nanorods (AuNR) prior to the gelation process.

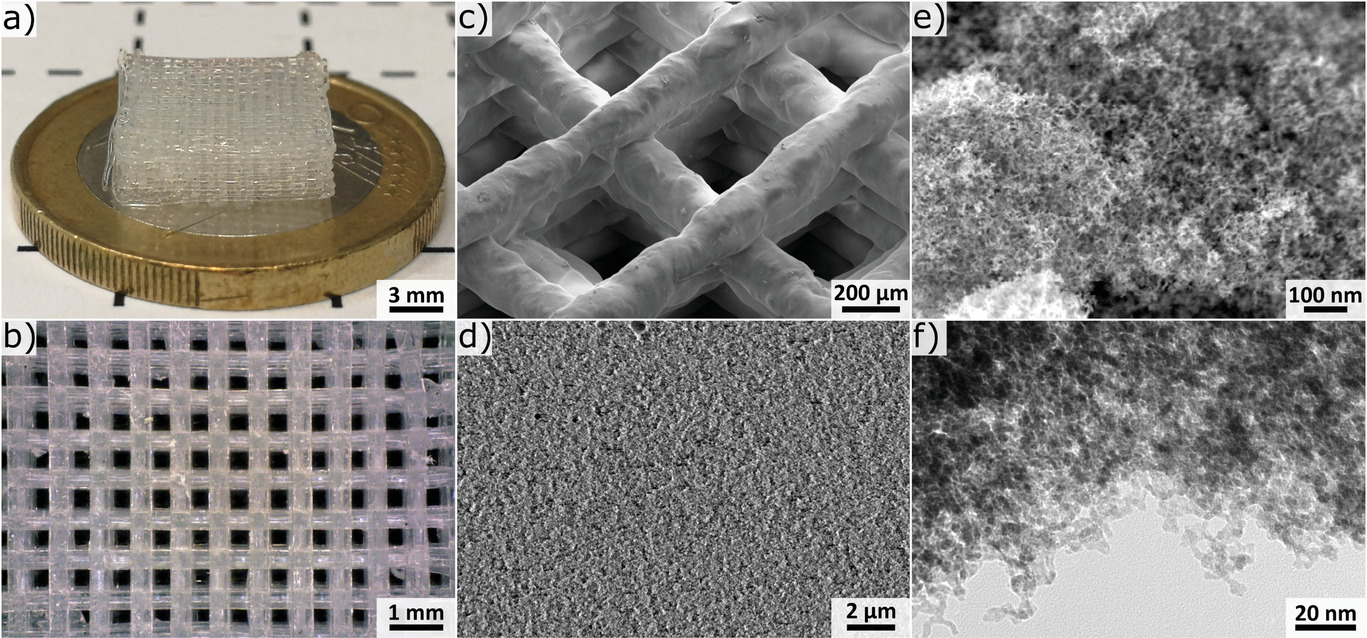

The team demonstrated the design flexibility of their method by printing geometries with high shape fidelity and precision, including void-free cubes, 3D grids, boats with large overhangs, and other multi-material geometries. The 3D printed aerogels contained a randomly organized interconnected mesoporous network with pore sizes in the range of 20nm, and large relative surface areas and low densities typical of conventionally cast metal oxide aerogels.

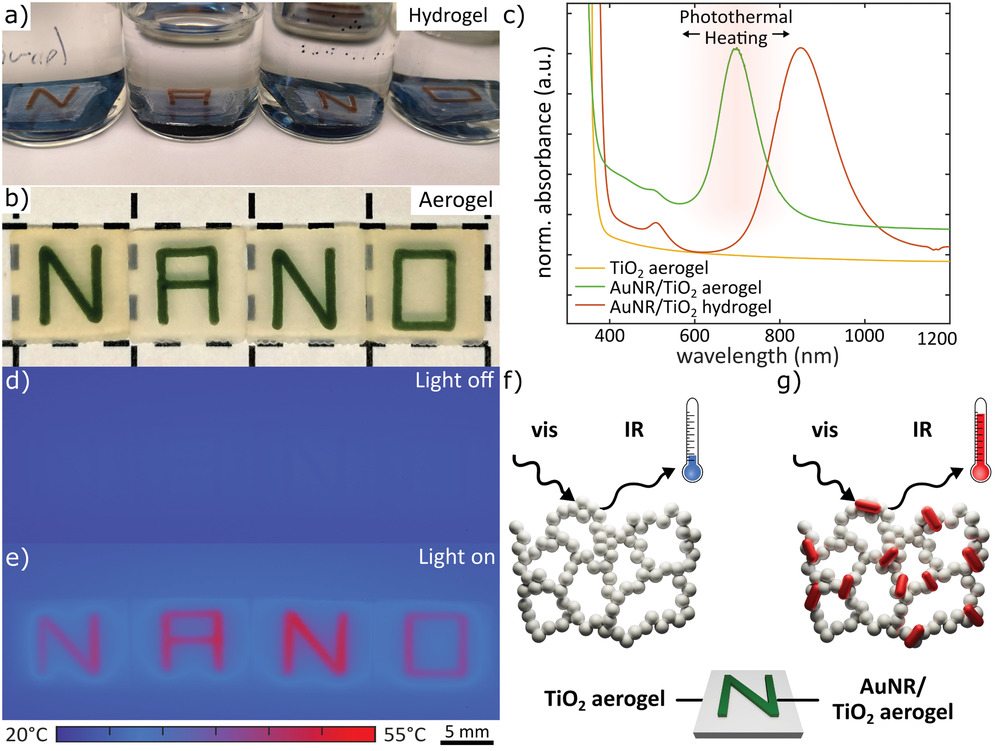

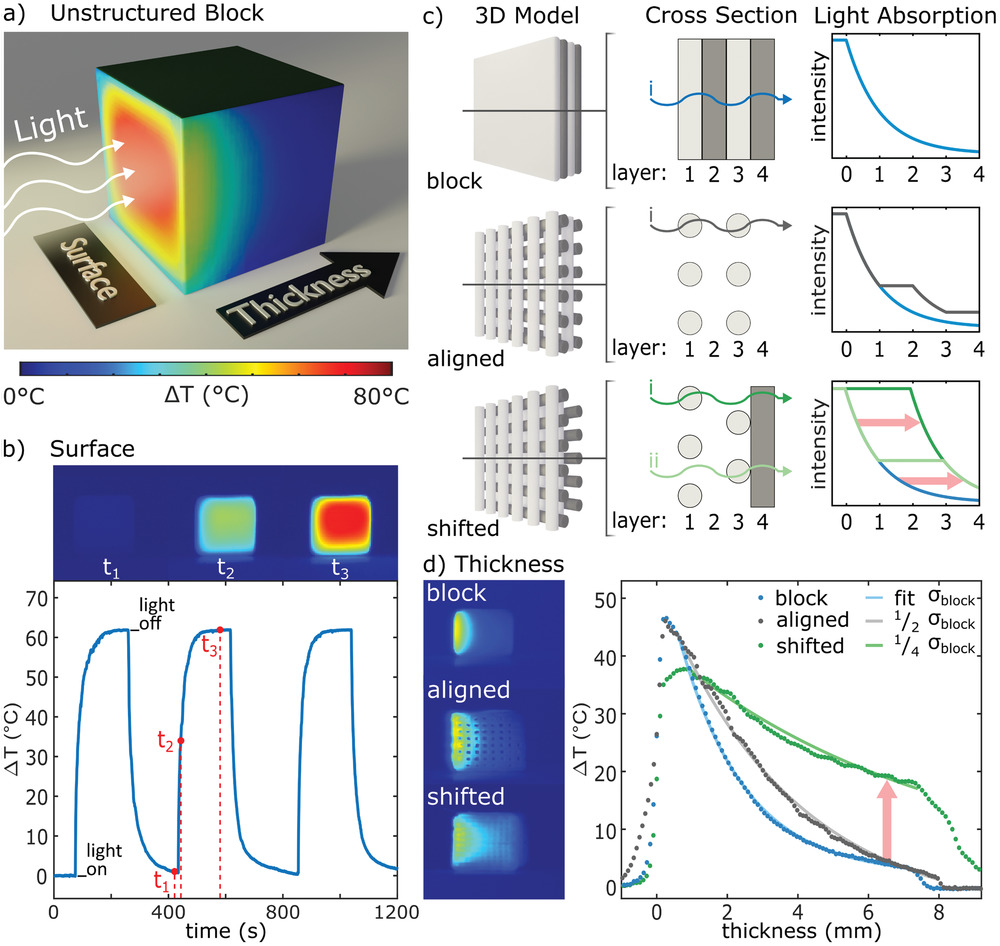

The researchers also showcased the design freedom of their method by successfully combining the superior thermal insulating capabilities of metal-oxide aerogels with the photothermic properties of plasmonic AuNRs. Their DIW 3D printing process defined not only the dimension of the printed material but also its composition and photothermal properties at any desired point.

The most significant breakthrough, though, was the ability to engineer the microstructure of their fabricated photothermal aerogel to deliver improved light penetration and more homogenous heating in 3D. According to the team, this could enable a new generation of photothermal devices for solar steam generation or thermochemical heat storage.

To achieve this, the team used two print heads loaded with different nanomaterials. On its own, TiO2 ink absorbs UV radiation and appears translucent, however when loaded with AuNRs features strong extinction in the visible and near-infrared (NIR) range due to plasmonic excitations. The researchers leveraged the free-form capabilities of their DIW technique to locally define the aerogel’s photothermal properties and improve its heat generation and light distribution properties.

In addition to TiO2, the approach can be applied to SiO2, Al2O3, or ZrO2 nanoparticle-based aerogels commonly used in photothermal devices. Photothermal heating of plasmonic nanoparticles has been leveraged in the past for prototype devices for clean water regeneration, energy generation, and photothermal catalysis, however until now has been limited to thin films due to the inability to structure nanoscopic properties on a 3D macroscopic scale.

By enabling more homogenous heat generation in a macroscopic object, the researchers believe their DIW 3D printing technique offers a completely new approach to fabricating large-scale 3D structured photothermal devices.

Further information on the study can be found in the paper titled: “Additive-free, gelled nanoinks as a 3D printing toolbox for hierarchically structured bulk aerogels,” published in the Advanced Functional Materials journal. The article was co-authored by M. Rebber, M. Trommler, I. Lokteva, S. Ehteram, A. Schropp, S. Konig, M. Froba, and D. Koziej.

Fabricating aerogels via DIW

DIW 3D printing has been previously explored for producing aerogels with optimized properties, with some notable developments occurring over the past year.

In March 2021, researchers at the UC Santa Cruz and the Merced nAnomaterials Center for Energy and Sensing (MACES) used DIW to fabricate porous carbon aerogels for electrodes in ultra-low temperature supercapacitors, which could power future missions both on Earth and in space. Funded by NASA, the research sought to reduce heating needs for vehicles and devices used in future missions within extremely cold environments.

Elsewhere, scientists from the University at Buffalo developed a novel water-purifying graphene aerogel using DIW that could be scaled for use in large wastewater treatment plants, while researchers at Lawrence Livermore National Laboratory used DIW to produce flow-through electrodes made from graphene aerogels for electrochemical reactors, reportedly achieving reactor performance improvements of up to 100x.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows hierarchical architecture of a 3D printed TiO2 aerogel. Image via Advanced Functional Materials.