The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Researchers from Lawrence Livermore National Laboratory (LLNL) have started using 3D printing to produce flow-through electrodes (FTEs) for electrochemical reactors, reportedly achieving reactor performance improvements of up to 100x.

Using direct ink writing, specifically, the LLNL team was able to 3D print customized porous electrodes made from graphene aerogels. The printed structures are crucial for a whole host of electrochemical reactions, such as the conversion of CO2 and other molecules into useful energy products.

By leveraging the design freedom offered by additive manufacturing, the researchers found that they could better control the flow passing through their 3D printed FTEs. In the context of an electrochemical reactor, this can mean improving mass transfer and maximizing reactor performance.

“We are pioneering the use of 3D reactors with precise control over the local reaction environment,” explains LLNL engineer Victor Beck, lead author of the study. “Novel, high-performance electrodes will be essential components of next-generation electrochemical reactor architectures. This demonstrates how we can leverage the control that 3D printing offers over the electrode structure to engineer the local fluid flow and induce complex, inertial flow patterns that improve reactor performance.”

Mass transfer and electrochemical reactors

Electrochemical reactors are typically used to convert chemical reactants into a more useful form of energy, namely electricity or fuel. According to the LLNL researchers, the commercial viability of these reactors is largely dependent on achieving greater mass transfer, which is simply defined as the transport of fluid reactants onto reactive surfaces through electrodes. For this, we need FTEs capable of controlling and engineering flow.

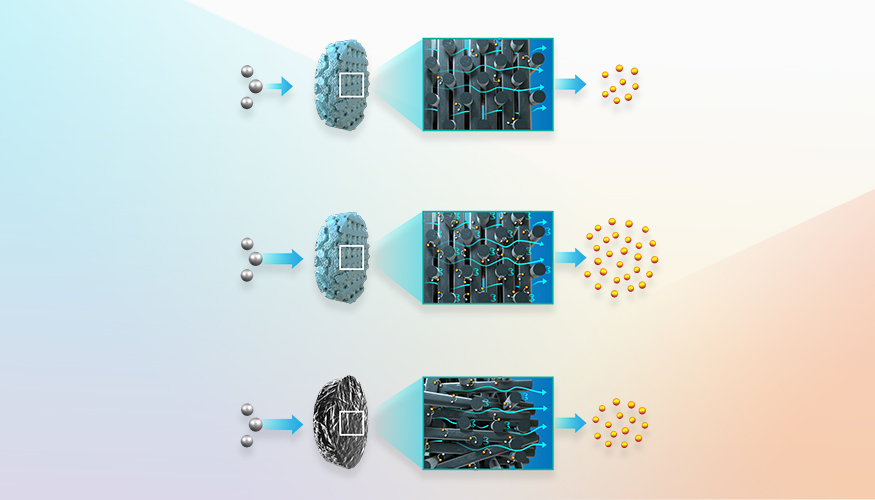

Until now, FTEs have been manufactured using ‘disordered media’ such as carbon fiber-based foams and felts. While cost-effective, these randomly ordered materials often result in uneven flow and mass transfer distribution, which is detrimental to reactor performance.

By opting for 3D printed aerogel electrodes instead, the researchers demonstrated that they could customize the FTEs’ flow channel geometries to optimize the reactions in the reactor, all while alleviating the shortcomings of traditionally manufactured FTEs.

“Gaining fine control over electrode geometries will enable advanced electrochemical reactor engineering that wasn’t possible with previous generation electrode materials,” adds co-author Anna Ivanovskaya. “Engineers will be able to design and manufacture structures optimized for specific processes. Potentially, with development of manufacturing technology, 3D printed electrodes may replace conventional disordered electrodes for both liquid and gas type reactors.”

3D printed graphene aerogel FTEs

The FTEs were printed in complex lattice structures, which reportedly enhanced mass transfer by 1-2 orders of magnitude (10x – 100x) when compared to previous 3D printing attempts. LLNL’s FTEs also achieved reactor performances that were on par with conventional disordered materials, which is a very promising result.

Swetha Chandrasekaran, a co-author of the study, said, “By 3D printing advanced materials such as carbon aerogels, it is possible to engineer macro-porous networks in these materials without compromising the physical properties such as electrical conductivity and surface area.”

The team has stated that the success of the study will now enable them to explore the effects of engineered electrode architectures without relying on costly industrial manufacturing processes. LLNL is also currently working on 3D printing more robust electrodes and other reactor parts using resin-based micro-stereolithography and two-photon lithography techniques.

The 3D printing of electrodes isn’t a new concept, although it is still largely limited to the academic sphere. A team of researchers from Oak Ridge National Laboratory and the University of Tennessee has previously developed a method of 3D printing electrodes for complementary metal-oxide-semiconductor (CMOS) circuitry. Specifically, the scientists used a Nanoscribe Photonic Professional GT two-photon polymerization system to nanoprint polymer structures directly onto semiconductor chips, where they could be carbonized.

Elsewhere, scientists have previously 3D printed electrodes capable of detecting mycotoxins in food, paving the way for a novel method of food safety assurance. The poisonous metabolite is produced by the Fusarium species of fungi and can typically be found in maize products containing wheat such as cereal.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed lattice electrode geometries. Image via LLNL.