Personalized medicine is becoming the standard as a global model for healthcare. In this model, the patient’s individual profile leads decision making. Personalized 3D printing is part of this movement and rapid prototyping services makes it happen. Especially in plastic or reconstructive surgery, custom made products are transforming the industry.

Reconstructive Surgery

The global market for cosmetic and reconstructive surgery will rise to $27 billion by 2019, according to a report by Research and Markets. Segments include nonsurgical treatments such as injectable products, energy based devices like lasers, and cosmetics. Surgical or minimally invasive procedures include body contouring, facial reconstruction, and cosmetic implants. 3D printing introduces a new level of precision for this fast growing market and offers patients the promise of personalized medicine.

Developing Segments

The needs of physicians, nurses, and other healthcare professionals are always changing. However, some areas of surgery have more room to develop than others and are therefore ripe for rapid prototyping services. The Freedonia Group has released a comprehensive report on the industry and it details the many products in this market.

- Lasers – light-based systems including intense pulsed light systems are trending higher as consumers desire more minimally invasive procedures.

- Garments – after surgery, patients are often counseled to wear special garments to help heal faster and better. For example, after liposuction, the waves or edema may cause ripples in the skin, a problem solved by compression garments. Since every person is different, custom made compression garments will fit better, minimize negative surgical effects, and allow the patient to move more comfortably.

Following the recession, demand for cosmetic or reconstructive surgical procedures is rising. Many procedures are going mainstream and are not just for the wealthy. Additionally, male customers are making their way to the surgeon’s office as the stigma of plastic surgery is fading.

Rapid Prototyping in Head and Neck Surgery

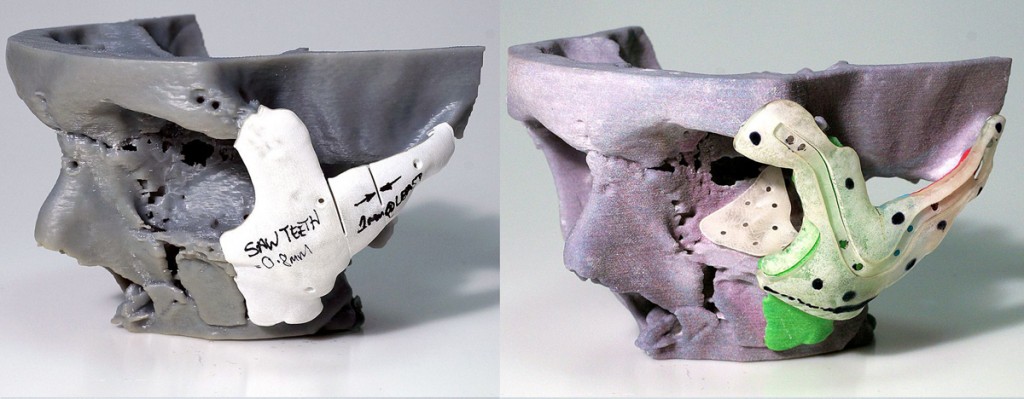

Applications for rapid prototyping are increasing in surgical procedures and one paper outlined the results for otolaryngology (head and neck). The areas of image/guidance, surgical simulation, and patient-specific modeling demonstrate the role of advanced fabrication technology. The study examined products in skull surgery, sinus surgery, and maxillofacial reconstruction.

The study authors identified three prototypes that would be useful in training new doctors including a model of a sinus system, a skull to practice surgery, and personalized mandible for specific patients. To make the prototypes, the physicians took 3D images of a live patient or a cadaver. Board certified surgeons and surgeons-in-training rated the prototypes positively. Authors concluded that fabrication of products is useful, “across a variety of otolaryngological sub-specialties suggests an emerging role for rapid prototyping technology in surgical education, procedure simulation, and clinical practice.”

Ophthalmologic Microsurgery

Researchers have used rapid prototyping to create a new manipulator system for ophthalmologic microsurgery. The system maintains a fixed-point of rotation at the surface of the eye, acting in concert with the da Vinci Surgical System for gross positioning. Robotic tests found the prototype was mechanically fit and surgical sclerectomy demonstrated reduced trauma during the surgical procedure. The study was published in Studies in Health Technology and Informatics.

Surgery Prototype to Diagnose Appendicitis

When a patient goes to the emergency room, complaining of pain in the abdominal area, physicians suspect appendicitis. However, in half the cases, the patient’s’ symptoms are unclear, so doctors have been searching for alternative imaging diagnostics. Many patients are sent home and develop a perforated appendix while others patients undergo unnecessary surgery. These mistakes cost billions of dollars a year in medical malpractice suits, lost wages, and hospital charges.

In one effort, researchers developed a device with rapid prototyping to rapidly assess appendicitis. A device called Trocamera was successful in visualizing the intra abdominal structures and capturing images. The prototype was first used on a pig and then human cadavers before use on emergency room patients. Surgeons have approved of the preliminary findings and said that the novel device allowed for rapid recognition of normal and abnormal structures in the abdomen.

Endoscopic Surgical Stapler

A group of surgeons designed and built an endoscopic surgical stapler prototype in three months. These physicians felt that all surgeons, especially laparoscopic surgeons, crave instruments that feel good in the hands and have precise and intuitive controls. Because of the precision and hand-feel necessary, perfecting an instrument can take many design modifications, a lot of time, and funding. This group of surgeons decided to try rapid prototyping to make their instrument.

In a paper reporting their progress, the authors state that they were able to test new designs in minutes and reduce their development times by many months. They said that surgeons liked their design, finding it comfortable and refined. They intend to move the design into production.

Rapid Prototyping

With the demand for cosmetic or other surgical procedures rising, innovators have many opportunities to invent new products, either just a part of a device or product or the whole thing. Prototyping services are essential partners in the development process as they provide comprehensive services and multiple technologies to bring a product to market. Ronan Ye, a manager at 3E Rapid Prototyping, shares his insight on this “We are seeing much more demand for these products in healthcare and in the automotive industry here in China. We definitely anticipate this demand to keep growing.”

As medicine is a global market and the Asian market is an active consumer of cosmetic procedures, a prototyping company in Asia is a definite advantage. China’s manufacturing sector offers machining, injection molding, and vacuum casting, among other technologies. The new generation of Chinese manufacturers has established quality control systems and worked with international clients. They complete projects quickly, are competitive in price, and have raised the standards for quality workmanship. In the rapidly growing personal medicine movement, a rapid prototyper on your side could make all the difference.