Milan, my hometown, is hardly a city that you would consider “futuristic” or even future oriented. A large part of the population is ageing and the often grey-ish, smoggy climate certainly does not help. With the World Expo set to take place here in 2015, and Milan Design week growing in popularity, the city has nevertheless become a hub for designers and personal fabrication. ITALYmaker, Milan’s first 3D Print Shop, has been at the heart of this revolution and is still going strong.

Milan is 3D Hubs’ second biggest city behind NYC for registered 3D printers. There are close to 10 Fab Labs, one 3DiTALY franchise and Idea Factory, the world’s only 3D Print Shop with an EOS Formiga P110 on its premises. Founded by Guido Maurizio ITALYmaker, however, is the shop that best embodies the promise of the neighbourhood factory and it is still working hard to make that dream come true.

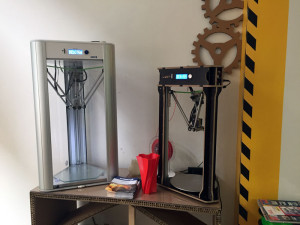

Maurizio opened up the shop in November 2013 with just a couple of PowerWASP 3D printers inside a small space, strategically located close to Milan’s Politecnico University in Bovisa. What he did have a lot of was experience in prototyping, engineering, 3D design and 3D printing assembly. He immediately formed a partnership with WASP, Italy’s main Delta 3D printers manufacturer. He told me that he chose them because he believes that the company, built and run by Massimo Moretti, invests heavily in development and focuses constantly on improving the quality of the 3D prints.

The business is not going to make Guido Maurizio rich but it is definitely growing, especially as a source of 3D printing awareness. When I visited last week, Guido was holding a workshop in the store’s dedicated area. In fact knowledge seems to be, at this point, the product customers seek and appreciate the most. Fortunately Guido has plenty of that to go around, since he began 3D modelling in 1998 at MYR Design, and his passion for personal manufacturing does the rest.

Just like early computer shops, ITALYmaker also offers custom-built 3D printers, assembled to fit the customers requirements, for example in terms of size and presence of options such as a heated plate and enclosed 3D printing area. Maurizio’s objective is to build a community of people empowered by personal manufacturing, who can collaborate to build the future.

Just a couple of weeks ago a friend of mine in the US saw that a skyscraper in Milan, called the Bosco Verticale, was voted the best high rise in the world because it is covered with many square meters of trees and vegetation. He said that is what future cities will look like, and I replied that Milan is about as far from a future city as it gets. Perhaps it is time to (ITALY)make it into a future city.