Manufacturers have used 3D printing for several years to create everything from automobile parts to submachine guns to eyeglasses. However, the idea to use such technology to create large building structures is a relatively new one. As the research institutions highlighted below suggest, it is indeed possible to create single-family dwellings, commercial structures, and larger buildings, potentially with the efficiency and speed that other users of 3D printing already enjoy.

University of Southern California

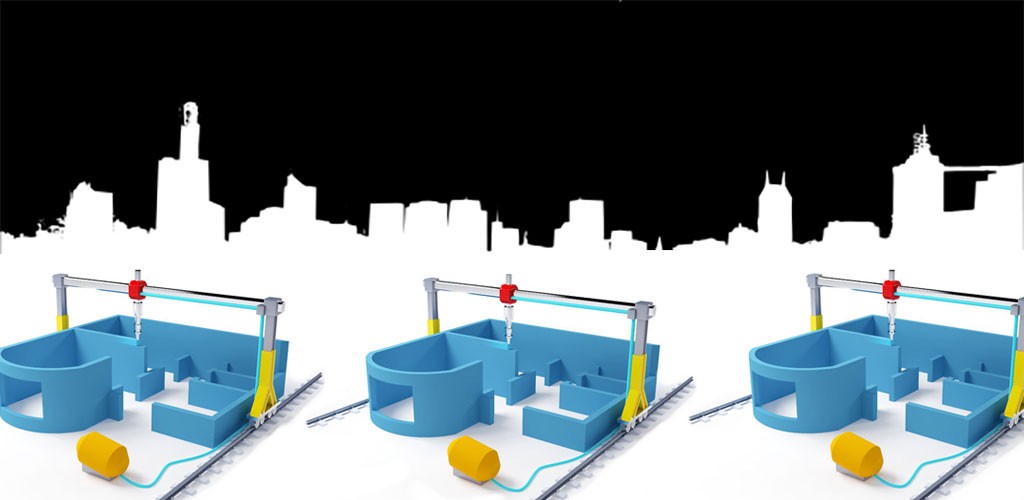

Behrokh Khoshnevis is a professor of industrial and systems engineering with the University of Southern California and the director of the Center for Rapid Automation Fabrication Technology, also known as CRAFT. Khoshnevis has developed Contour Crafting (CC), a 3D printing process that releases concrete through an attached nozzle. The technology has the potential to enable construction workers to develop the framework for a 2,500 square foot single family home in approximately 20 hours. The 3D printer sits atop an oversized sawhorse while laying down lines of concrete one layer at a time. The CC system can also be manipulated to lay interior work, tiling, finishes, and metal ceilings.

Bartlett School of Architecture

A group of students at this UK school created 3D printing technology that creates large furniture pieces and other structural elements. The students have used extrusion and power printing, two existing 3D printing techniques, to create a new form of supported extrusion. For the first step, they extract ready-mixed concrete layer by layer from an industrial robotic arm. They then place this material over supported granular material. This allows for much higher printing resolution as well as a greater variety of design forms. The entire process takes less than 10 hours to complete and instills a renewed sense of craftsmanship to the field of architectural design.

Vanderbilt University

In July of 2015, over 30 environmental engineering experts met at Vanderbilt University to discuss emerging 3D printing technology and how they could use it to improve efficiency in the construction industry. Recognizing that the decades-old method of mixing cement with sand and water to create a slurry is slow, labor-intensive, and costly, the industry experts discussed taking a lesson in technology from these ongoing projects:

- A 12 x 12 pavilion made from 3D printed blocks in a traditional Thai flower pattern

- A case study for a 3D printed house at a Beijing resort

- Construction of a six-story apartment building from recycled concrete materials

- Construction of a miniature cement castle using components created by a 3D printer

The success of these projects was encouraging to architects who can use 3D printing technology to create buildings in new shapes and contractors who now have the freedom to build new structures without relying on external forms. Civil engineers who attended the Vanderbilt University conference look forward to replacing cement-based mixtures with more efficient materials created by 3D printers.

University of California, Berkeley

A team or researchers at the University of California’s flagship institution, led by the associate professor of architecture Ronald Rael, recently produced a powder-based concrete structure called Bloom using 3D printing technology. This process involves printing out a dry cement powder and then spraying it with water to cause the structure to harden. The major benefit of this method is that it creates a finished structure that is more complex and precise than those created using the extrusion method. The polymers mixed with the cement and fibers produce lightweight parts that allows for less waste and a lighter finished product.

Economic Viability

Despite the large amount of research done at academic institutions around the globe, talk of transforming the construction industry through 3D printing has been largely theoretical. However, recent accomplishments by a Chinese company Winsun suggest that the future may have arrived. According to a recent article in The Guardian, Winsun recently constructed a 11,800 sq. ft. villa using a custom 3D printer and a feedstock made from recycled rubble, fiberglass, steel, cement and binder.

The cost savings generated by using this cutting-edge technology are significant compared to traditional construction methods, according to Zheng Jian, general manager of Winsun’s Suzhou operations, who tells The Guardian, “It took eight people one month to finish the £105,000 villa. If traditional construction methods were used it would take 30 people three months. Costs are halved.”

Winsun now boasts an agreement with the Egyptian government to build 20,000 single-story dwellings in the desert using a variation of their technology. That project will use a feedstock largely comprised of desert sands and the construction will be done on-site. Should that project be a success, it would be the greatest validation of the economic viability of 3D-printed technology for large-scale construction to date.

Impressive as these recent developments sound, there still are many challenges ahead for 3D printing in construction. Although the cost savings reported by Winsun on their villa project are significant, it’s unclear whether they factored in any of the costs of developing their highly secretive, custom 3D printer (a goliath reported to be 6.6 meters tall, 10m wide and 150m long). Additionally, they may face litigation at some point as Professor Khoshnevis of USC told The Guardian that Winsun representatives had met with him in 2013 and allegedly copied his innovation.

Like any new disruptive technology, the implementation of 3D printing in the construction industry will face more hiccups and roadblocks as it breaks into the mainstream. However, given the volume of research being done at institutions around the globe, the question of 3D-printing becoming a viable construction technology for large-scale structures appears to be more of a question of “when” rather “if.”