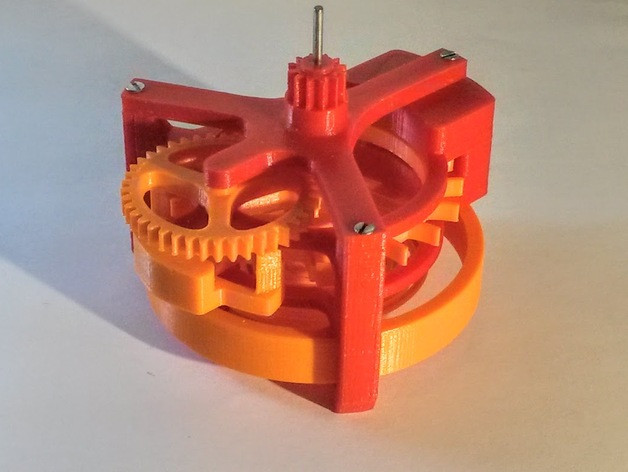

It may not become a commercial product anytime soon, but the Tourbillon clock created by (logically) Swiss designer and engineer Cristoph Laimer is certainly a prime example of what low-cost FFF 3D printing technology can achieve in terms of mechanical devices. In fact, it has already risen to Thingiverse celebrity status, with the complete 3D model – with accurate video instructions for assembly – featured on the 3D model network’s homepage.

A “Tourbillon” is an addition to the mechanics of a watch escapement developed around 1795 and patented by the French-Swiss watchmaker Abraham-Louis Breguet to counter the effects of gravity. It does so by mounting the escapement and balance wheel in a rotating cage. By continuously rotating the entire balance wheel/escapement assembly at a slow rate (typically about one revolution per minute), positional errors are averaged out.

Laimer designed the watch with Autodesk Fusion 360, and 3D printed it with an Ultimaker 2. It has a Swiss lever escapement, embedded in the Tourbillon, and is driven by a 3D-printed spring,running about 35 minutes (with the addition of a wire retraction spring made from steel it would perform better). The standard deviation is less than 0.5 seconds per minute, which is not bad for something entirely made of plastic. The next challenge will be to actually get it into a pocket but, then again, there already are 3D printing technologies around that might just be able to do that.