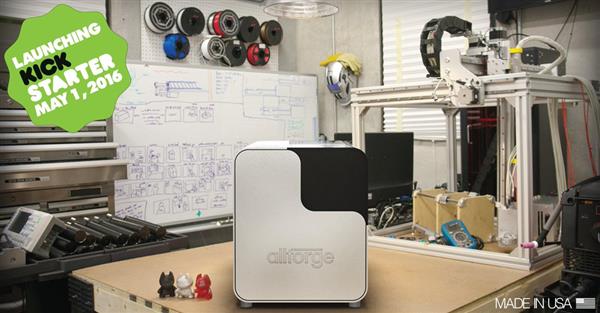

Allforge has started taking advance orders for its desktop 3D molding machine today.

Even with the 50% early-bird discount it is still a hefty $2,495 and the retail price will be $5000 when it officially launches in six months. The initial plan was to run a Kickstarter campaign, but the company decided to opt for advanced sales at the last minute.

With the Allforge you can load a mold that you make yourself with a 3D printer or on a mill, choose the quantity of items using an app on your phone and the desktop molder will take care of the rest. It’s hands-off mass production, on a table.

Different strokes for different folks

There are three models: Boss, Startup and Sweet.

The Sweet is designed to create candy and desserts, the Startup can make candy and melt plastics and the Boss can mold metal, plastic and sweets.

The confectionary-heavy approach might seem strange, but it’s a USP in its own special way and there certainly is a ready market of artisan confectioners that could use this technology to design their own sweets. It’s a way for children to get used to dealing with injection molding as well, making chocolate, taffy and wax creations in relative safety.

Upgrades are available

You can upgrade the machines as your confidence grows. So once you have mastered chocolate then you can step up and challenge yourself with plastic, or go the whole hog with metal.

The Startup will be more practical for most hobbyists and small businesses. This one turns pellets of ABS or PLA into specific molded shapes. It’s way faster than 3D printing and the unit cost is much lower.

So if a small business wants to create its own packaging, or it produces a lot of parts from plastic, then this can work in conjunction with 3D printing to create an effective production line on a desktop.

Buy prefabricated molds, or make them yourself

You can order the mold through 3D Hubs, or you can print one yourself and then simply load it into the Allforge to create a production run. This is ideal if you use a large number of the same, relatively simple part, as 3D printing can take hours and it simply isn’t cost-effective for some items.

Of course the Boss is the really intriguing one here as it could be an absolute gamer changer for home metal workers that can mold parts instead of milling or even printing them.

It opens up all kinds of opportunities to sell limited runs of ornaments and statues and people could even fabricate spare parts for domestic machines with plans downloaded from the web.

Get heavy with metal

You can’t use the Boss with every metal, but anything that melts below 650 degrees Farehnheit is fair game. That covers the likes of Pewter, Tin and Cadmium, which are traditional modelling materials. The company reckons that serious users could potentially get the equipment up to 1200 degrees Farenheit and melt Aluminum, Magnesium and Zinc.

Aluminum and Magnesium in particular are used for high-performance parts in computing, remote control toys and other fields, thanks to their strength and light weight. So if the Boss does produce this kind of performance, then it should do well.

It’s fast, seriously fast

The making time for metal and plastic is listed as 5 minutes 32 seconds, but in reality the parts are created in seconds and cooling time is the limiting factor. The molder cannot produce another part until it has cooled, but this is still a quantum leap forward and most small businesses will live with the timescale.

Size is an issue

The only real limitation is the size. While the Allforge accepts molds up to 20x20x5cm, the company recommends using molds up to 20x20x2cm. That puts a real dampener on it for some people, but it will be more than enough for a vast number of hobbyists and small businesses that will have a specific application in mind.

It’s a fascinating addition to the desktop fabrication market and this kind of injection molder could form an ideal complement for a 3D printer. It effectively allows mass production on a small scale, which will give artists, home businesses and advanced hobbyists a world of opportunities.

It’s a pricey toy, or an invaluable tool. We’re crossing our fingers and hoping it’s the latter.