The month of February 2020 saw industry leaders come together for TÜV SÜD’s 2nd Additive Manufacturing Conference, alongside 3D printing-enabled medical breakthroughs and a landmark delivery of 3D printed parts within the maritime sector.

Read on for the standout developments of February 2020, which involved the likes of Renishaw, Wilhelmsen, Formlabs, COBOD, and Evonik.

TÜV SÜD’s Additive Manufacturing Conference

February got underway with the 2nd TÜV SÜD Additive Manufacturing Conference, held in the heart of Bavaria, which brought together 3D printing experts, industry leaders, and academics to share their thoughts on the implementation of industrial additive manufacturing.

During the conference, standardization and digitization were singled out as the gateways to a fully automated additive manufacturing system in years to come in regards to material testing, quality assurance, part certification, and process chains.

Space-time research expands for AM

Meanwhile, researchers from the Delft University of Technology (TU Delft) developed a method to concurrently optimize 3D printed structures and the fabrication sequence that creates them, specifically in the wire arc additive manufacturing process (WAAM).

Recently awarded the ISSMO/Springer prize from the International Society of Structural and Multidisciplinary Optimization (ISSMO), the research can be explained using the example of a robot building a bridge in a futuristic scenario, where the bridge must maintain its mechanical strength as it is being built in order to support the weight of the robot.

Wilhelmsen’s landmark maritime delivery

Global maritime industry group Wilhelmsen delivered what it claimed to be a “landmark commercial delivery” of 3D printed parts to dry bulk shipping company Berge Bulk. The delivery was part of Wilhelmsen’s Early Adopter Program with additive manufacturing service bureau Ivaldi Group, which was launched in late 2019 and involved the supply of 3D printed spare parts on-demand to ships and other vessels.

“This is just the beginning of the journey, and we are quickly expanding our offering, together with our key development partners, enabling our customers to benefit from the savings provided by 3D printing, digital inventory and on-demand localized manufacturing,” said Hakon Ellekjaer, head of venture, 3D printing, at Wilhelmsen Ships Services.

Research roadmaps and material exploration

Midway through February, a worldwide collective of researchers from various universities and institutions came together to produce a roadmap for 3D bioprinting, which was published in Biofabrication.

Summarising the current state of bioprinting, including recent advances of the technology, present developments, and challenges, the paper envisioned how the technology could improve in the future. Topics covered in the paper ranged from cell expansion and novel bio-ink development to stem cell printing and organoid-based tissue development, in addition to bioprinting human-scale tissue structures and multicellular engineered living systems.

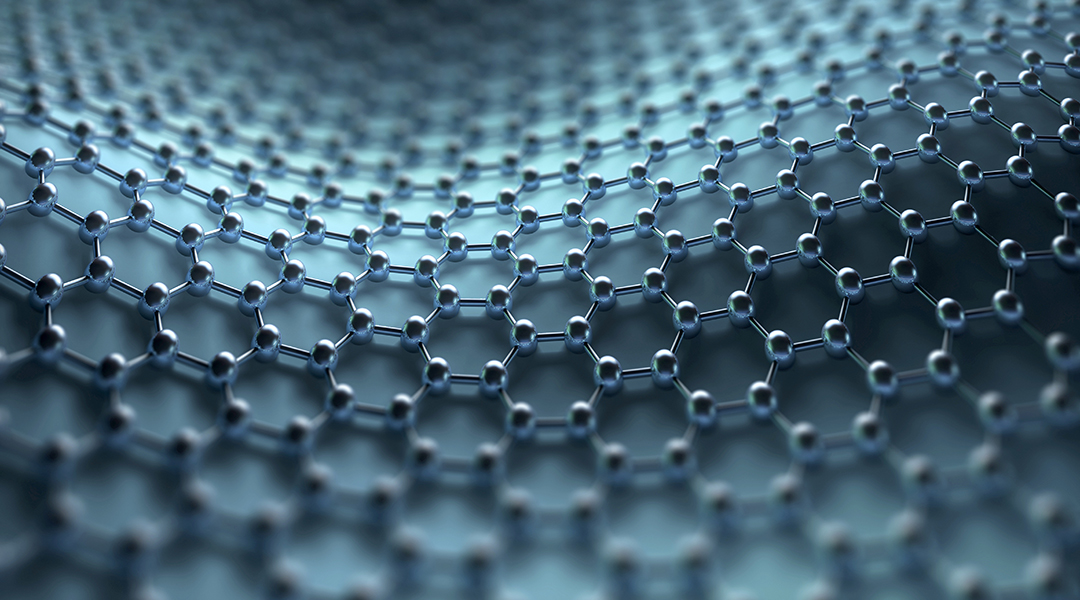

Elsewhere, research coming out of the Tokyo University of Science explored how water molecules react when they come into contact with the surface of graphene, revealing there is much to learn about the interaction between water and 3D printed materials.

“Surface water on carbon nanomaterials such as graphene has attracted much attention because the properties of these materials make them ideal for studying the microscopic structure of surface water,” said Professor Takahiro Yamamoto, leader of the study.

Advancing dental restorations

SLA 3D printer manufacturer Formlabs announced new materials from German dental 3D printing pioneer BEGO were to be used in Formlab’s Form 3B and Form 2 resin printers. Using these systems, dental professionals are now able to 3D print temporary and permanent crowns and bridges directly for patients.

Widely regarded as a specialist in the sector, BEGO has been developing dental-specific 3D printing materials for over two decades. Now, Formlabs’ printing systems will use BEGO’s materials to print permanent single crowns, inlay, onlays, and veneers, and temporary crowns and bridges.

Construction printing: Live

Danish 3D printing construction firm COBOD demonstrated its construction technology by 3D printing the walls of small four houses during the international Bautec construction exhibition in Berlin, between 18-21 February. The demo was completed using the company’s BOD2 3D construction printer, and aimed to provide an un-cut example of its technology in action to Bautec visitors.

“When you print live, it is not possible to hide anything,” explained Henrik Lund-Nielson, COBOD CEO. “With this live printing, we are documenting that our technology has the quality, robustness and stability to perform hour after hour, day after day.”

Evonik’s first 3D printing software tool

Towards the latter stages of February, German specialty chemicals company Evonik launched its first software tool for 3D printing, designed to help manufacturers select the appropriate additive manufacturing process for their desired part.

Developed by Israeli start-up Castor, in which Evonik invested in late 2019, the software aids users in their choices by taking into account the design’s geometry, material, and financial analysis.

Renishaw lands Parkinson’s study milestone

Rounding off the month on a positive note, UK-based engineering technologies firm Renishaw announced a milestone in a medical study seeking to help sufferers of Parkinson’s disease, for which it developed a patented intraparenchymal drug delivery device using 3D printing.

Initial results of the study were promising and indicated predictable and accurate placement of the neuroinfuse device, as well as significant efficacy and safety of both the device and the drug, CDNF, which was developed by pharmaceuticals experts Herantis Pharma.

Renishaw has since concluded an extension to the study, which is currently the only platform to facilitate repeated, intermittent infusions into the parenchyma, and enables patients to receive the infusions in an out-patient setting.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Fabian Meyer-Brötz, head of 3D printing at Peri, showcasing the end result for the printing on February 19, 2020. Photo via COBOD.