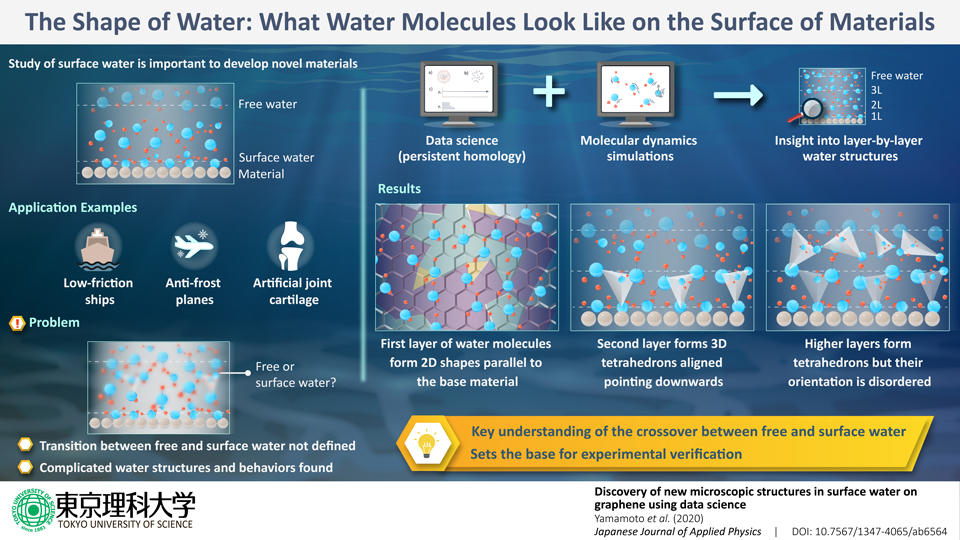

New research from the Tokyo University of Science has revealed what happens to water molecules on the surface of graphene. The study, led by Professor Takahiro Yamamoto, combined statistical data analysis tools with molecular dynamics simulations to explore the change in the structure of water when in contact with the carbon-based material, suggesting there is much to learn about the interaction between water and 3D printed materials.

Professor Yamamoto told 3D Printing Industry, “In a 3D printer, understanding and control of wetting on material surfaces is essential for the process of stacking layers. The wetting is determined by the microscopic structure of water adsorbed on the surface. However, the method to determine this has not been established yet. The present study proposes such a potential method based on a data scientific approach. The developed method is expected to be applied to not only graphite surfaces but also various materials surfaces.”

The results of the 2020 research, published in the Japanese Journal of Applied Physics, are expected to have major implications in marine and aircraft engineering, as well as being beneficial to implantation surgeries.

The importance of water dynamics

Water is a very common substance, found naturally in virtually every environment on the planet. The properties of the first few layers of water, called surface water, are especially important in material science as they determine how water flows in relation to the contact material’s surface.

Understanding how this water behaves and why it behaves how it does would allow material scientists to develop hydrophobic or hydrophilic materials and perhaps even change the properties of existing ones. Reducing water friction on the surfaces of ships would lead to greater fuel efficiency, or developing ice-resistant materials for airplanes could introduce new safety measures when flying in sub-zero environments.

Water molecules and graphene

The present study is focused on the interaction between water and graphene, which is an atomically flat material. This makes graphene a perfect contact material when studying the fundamentals of water’s interactional properties.

Professor Yamamoto explains: “Surface water on carbon nanomaterials such as graphene has attracted much attention because the properties of these materials make them ideal for studying the microscopic structure of surface water.”

Previous studies have already established that water, in contact with graphene, forms stable 2D shapes in both surface water and free water, the water away from the surface of the contact material. The differences between surface water and free water had not previously been determined however. The transition zone between these two groups is especially hard to characterize, which is what the Japanese study aimed to accomplish.

Due to the complexity of the research, multiple characterization methods had to be employed in conjunction with each other. Persistent homology (PH), a method from data science was mixed in with simulations of molecular dynamics. PH can be used in materials science to find stable 3D structures in chaotic fluids.

“Our study represents the first time PH was used for a structural analysis of water molecules,” remarks Prof Yamamoto.

When a single layer of water molecules is placed on the surface of graphene, the water molecules align in a 2D structure connected by their hydrogen bonds, parallel to the surface of the graphene. A second layer makes this structure 3D and unidirectional, forming a tetrahedral network pointing ‘down’ towards the surface of the graphene. A third layer maintains the tetrahedral 3D structure but makes it omnidirectional, where the tetrahedrons point in all directions. Any subsequent layers after the third are oriented in the same way as the third, suggesting this is where the surface water ends and the free water starts.

Professor Yamamoto states: “These results confirm that the crossover between surface and free water occurs within only three layers of water.”

The study is titled ‘Discovery of new microscopic structures in surface water on graphene using data science’ and was published in the Japanese Journal of Applied Physics on January 14th, 2020. It is co-authored by Koichiro Kato, Yuki Maekawa, Naoki Watanabe, Kenji Sasaoka and Takahiro Yamamoto.

What does it mean for 3D printing?

Although graphene is a relatively simple surface, and other more realistic surfaces are bound to have more complex water interactions, this study verifies the validity of the novel method used for characterization. 3D printed surfaces have not yet been examined in this depth due to the relative infancy of the technology, and Professor Yamamoto expects the approach to aid in the characterization of 3D printed surfaces in contact with water in years to come.

Perhaps the approach can be applied to the 3D printed graphene structures developed in California to determine any differences in graphenes produced using completely different technologies. Elsewhere, in Sweden, 3D printable graphene filament has been developed, suggesting a bright future in additive manufacturing for the carbon-based supermaterial.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Featured image shows structure of graphene. Image via Science Photo Library.