As 2020 draws to a close, 3D Printing Industry looks back over a rather tumultuous and unsettled year, which for reasons obvious to many has left a lasting impact across almost all areas of modern life as we know it. So, how has additive manufacturing fared in the face of the Covid-19 pandemic that has largely dominated the last 12 months, and what other emerging 3D printing trends, developments, and applications have come to the fore in that time?

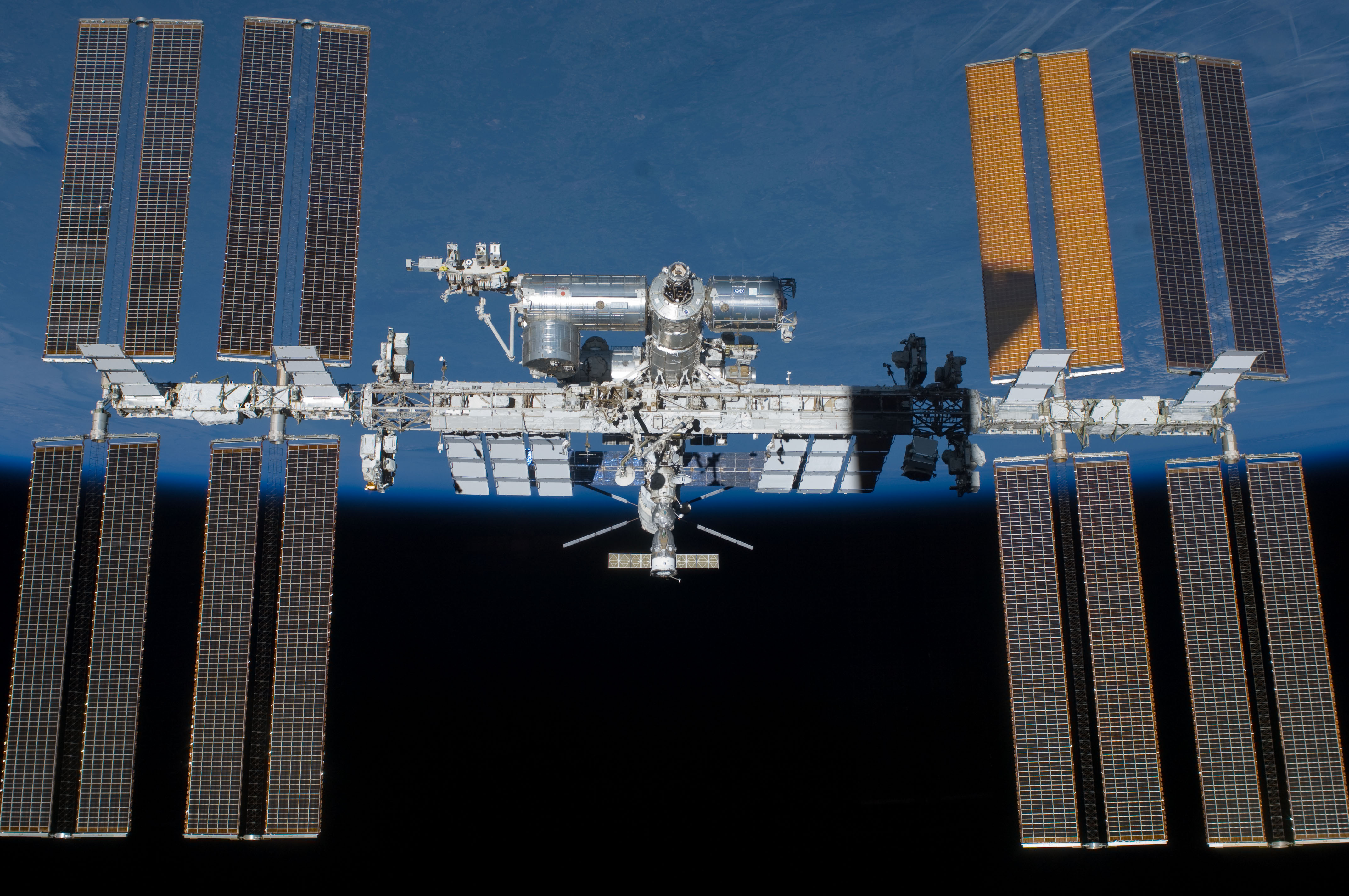

In January, 3D printed parts powered the engines of the largest twin-engine jetliner to date, new means of bioprinting tissues were developed, and biomedical researchers announced plans to deliver 3D printed miniature hearts to the International Space Station (ISS).

Read on to discover the standout developments from the first month of 2020.

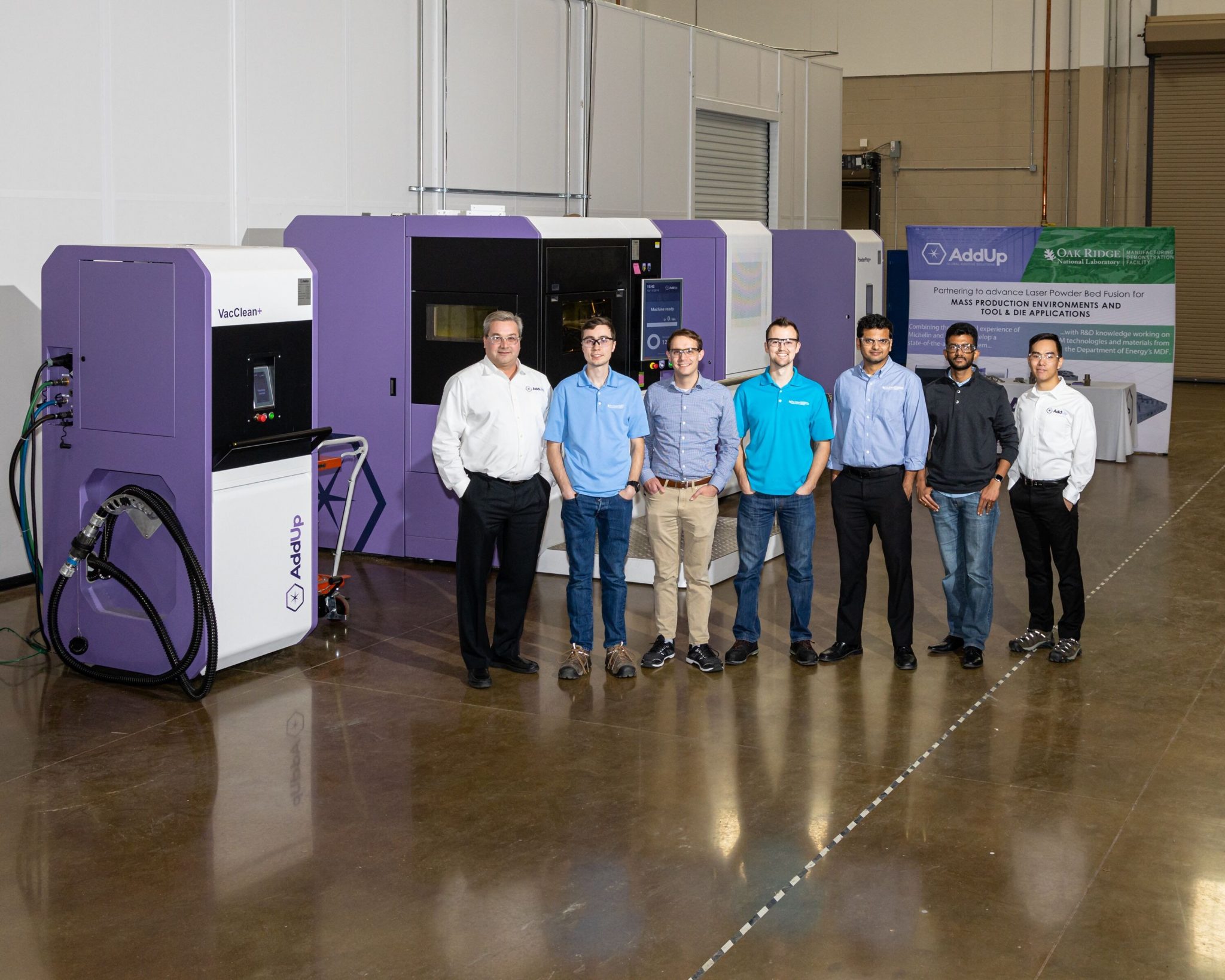

AddUp and ORNL join forces to advance LPBF

Kicking off the year, French industrial 3D printer provider AddUp entered into a $2.7 million agreement with the Oak Ridge National Laboratory (ORNL) to develop metal additive manufacturing materials processes for tooling.

The pair announced a focus on advancing laser powder bed fusion (LPBF) technology, alongside plans to investigate solutions for the geometric constraints concerning tooling within mass production environments, such as overhang angles, thin walls, and process repeatability.

Medical bioprinting advances

Meanwhile, 3D printer OEM 3D Systems and Israeli bioprinting material developer CollPlant partnered to create tissue and scaffold bioprinting solutions for third party collaborators.

In a bid to accelerate breakthroughs in regenerative medicine, the firms announced plans to create integrated 3D bioprinting solutions, consisting of 3D Systems’ bioprinters, CollPlant’s bio-inks, and new formulations of CollPlant’s proprietary rhCollagen-based bio-inks, to allow the manufacture of tissues and scaffolds.

Elsewhere, researchers from the MIT Media Lab, Harvard University’s Wyss Insitute, and the Dana-Farber Cancer Institute collaborated to develop a Hybrid Living Material (HLM) fabrication platform – essentially, a method to 3D print objects which can control living organisms. Within the HLM platform, a soluble support resin was used with a structural resin material and a multi-material inkjet-based 3D printer to produce 3D printed parts that became absorbent and capable of retaining chemical signals to control the behavior of living organisms.

“We can define very specific shapes and distributions of the hybrid living materials and the biosynthesized products, whether they be colors or therapeutic agents, within the printed shapes,” explained Rachel Soo Hoo Smith, Graduate student, MIT Mediated Matter Group.

Automated robotics

ABB Robotics, the robotics division of multinational electrical equipment firm ABB, added 3D printing software to its robotics simulation program in January, claiming users would be able to program ABB robots to begin additive manufacturing production in 30 minutes. With the addition of the new 3D printing software, the firm aimed to eliminate manual programming for its customers in order to facilitate faster prototype production.

“With our new 3D printing software, we are offering customers a faster and more streamlined 3D printing process,” said Steven Wyatt, Head of portfolio and digital at ABB Robotics. “Coupled with the high performance of our robots, this means manufacturers can now produce high-quality 3D printed objects for a variety of industrial applications more efficiently.”

Additive manufacturing in aerospace

January saw a couple of 3D printing-related announcements from the aerospace sector, the first of which involved the signing of a Memorandum of Understanding (MoU) between multinational aerospace firm BAE Systems and metal 3D printer manufacturer Renishaw to improve manufacturing processes for combat aircraft systems.

At the time of the announcement, BAE Systems’ manufacturing and materials strategy and technology director, Andy Schofield, said: “This agreement allows us to create a more open and collaborative environment to share ideas and knowledge. In an environment of fast-developing technology and challenged budgets, collaboration, and innovation are absolutely essential in order to retain cutting edge capability.”

Just over a week later, GE Aviation revealed that multinational aerospace giant Boeing had completed the first flight of its 777X jet, powered by twin GE9X engines equipped with over 300 3D printed parts. The world’s largest twin-engine jetliner and passenger plane, the 777X took off from Paine Field in Everett, WA, on January 25.

President and CEO of GE Aviation, David Joyce, said the firm was “proud to be the power under the wings of the 777X and provide this state-of-the-art aircraft with GE’s advanced technology.”

Energizing turbomachinery

Around the same time, GE was awarded around $1.3 million to accelerate the development of 3D printed turbomachinery parts, in partnership with ORNL and the Palo Alto Research Center. The funds were granted by the U.S. Advanced Research Projects Agency-Energy’s (ARPA-E) DIFFERENTIATE program, which aims to reduce the timeline for designing and validating 3D printed components by up to 65%.

Upon receiving the funding, leader of GE Research’s additive efforts, Brent Brunell, said: “One of the keys to enabling the widespread use and benefits of 3D printing is the reduction of the time it takes to create and validate defect-free 3D component designs.

“Using multi-physics enabled tools and [Artificial Intelligence] AI, we think we can beat the timeline for some traditional manufacturing processes by automating the entire process.”

Singapore welcomes digital manufacturing

Towards the end of January, HP, NTU Singapore, and the National Research Foundation Singapore officially opened the HP-NTU Digital Manufacturing Corporate Lab, offering skills development programs to train firms in additive manufacturing and digital design. First announced in 2018 with an estimated value of $84 million, the lab’s main aim is to support research development within 3D printing, including advanced polymers, tissue bioprinting, new materials and applications, and 4D printing.

Additionally, more than 60 researchers within the lab are exploring AI, cybersecurity, and machine learning, while new design software tools are being developed for material optimization.

3D printing enables smartphone diagnosis

Using your smartphone to diagnose parasitic diseases became possible at the start of the year, after researchers from the University of Grenada and the University of Glasgow 3D printed a plastic attachment that works in tandem with a phone’s rear camera to illuminate and identify parasites within humans and livestock.

The researchers hoped providing an accessible and affordable diagnosis tool would aid those living and working in remote areas of developing countries with limited access to resources for such tools.

Sending hearts to space

Rounding off January’s standout developments is the collaboration between biomedical researchers from Texas Tech University Health Sciences Center El Paso (TTUHSC El Paso) and the University of Texas at El Paso (UTEP) to develop and deliver 3D printed ‘artificial mini-hearts’ to the ISS.

Produced via a combination of human stem cells and 3D bioprinting, the ‘artificial mini-hearts’, also known as cardiac organoids, will enable the scientists to gain insight into how microgravity affects the function of the human heart. Funded by the National Science Foundation and the ISS’s U.S. National Laboratory, the project will take place over the next couple of years.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the ISS Exterior. Photo via Roscosmos/ NASA/TTUHSC El Paso.